|

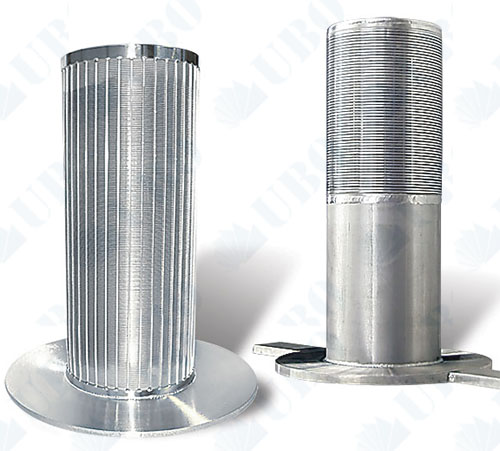

Water well stainless steel sand free screen is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights.

Inquiry now

|

Wedge Wire Screen |

|

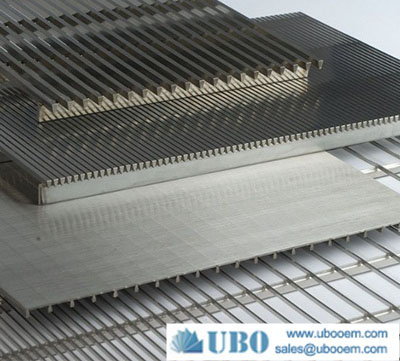

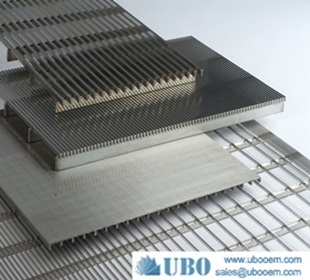

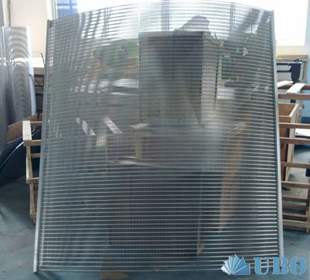

UBO high quality custom built flat panel wedge wire screens, manufactured either framed or unframed with a variety of support rods, offers a high strength, long lasting, economical solution to the market. They come in commonly shaped wedge wire profiles and offer good screening efficiency across a wide range of applications. Flat wedge wire screens are excellent for use to de-water, de-slim, drain and rinse, wet classify, dry classify, filter, dry and cool. They are recommended for use in any application that requires efficient liquid-solid separation.

Inquiry now

|

Wedge Wire Screen |

|

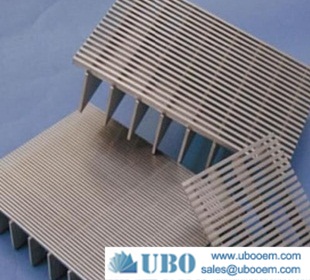

The fine wire sieve bend screen, also known as the wedge wire run down screen, wedge wire side hill screen, DSM screen, Parabolic screen, wedge wire curve screen and so on. The sever bend screen could be custom made and designed according to the application. They are usually used to separate solids from liquids. The curved screen of sieve bend provides greater capacity than flat wedge wire screen due to increased gravitaonal forces on material frowing against the curve.

Inquiry now

|

Wedge Wire Screen |

|

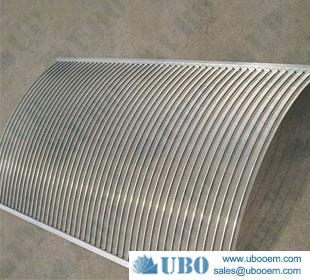

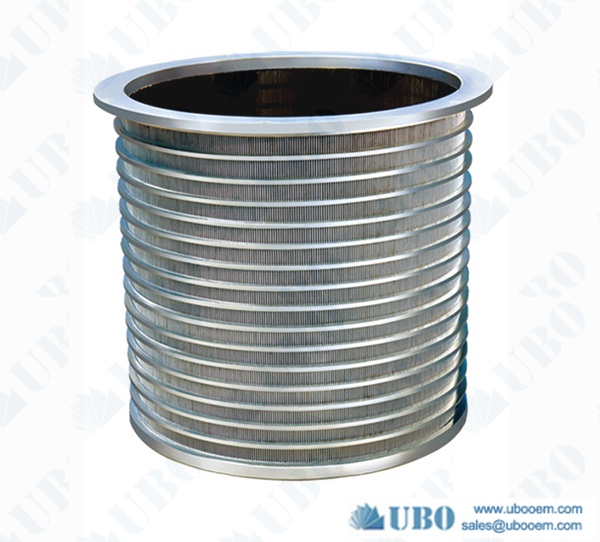

radiused screen cylinder is used in a wide variety of processes across several industry sectors. We use state-of-the-art manufacturing techniques that place our products at the cutting edge of wedge wire screen construction. Flat panels can be designed and manufactured according to customer specifications and come in a wide range of grades - from fine gap screens for small particle sizes to heavy duty screens for heavy load applications.,

Inquiry now

|

Wedge Wire Screen |

|

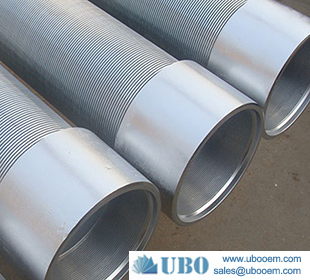

slotted screen cylinder are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Inquiry now

|

Wedge Wire Screen |

|

SS Wedge Wire v wire wrapped water well screen tube (V-shaped wire). The Industrial wedge wire wrapped screen have a robust structure and large open area, as well as accurate slot dimension. At the same time, wedge wire screens pipe have many advantages such as heat-resisting, anti-corrosive, good machine capability,long service life, safety and reliability and so on. It can be used in many kinds of medium filtering.,

Inquiry now

|

Wedge Wire Screen |

|

Drilled screen Cylinder are placed in a housing, inline with the flow to capture expensive media from traveling downstream. We can design the Drilled screen Cylinder to capture media particles of any size. With the continuous open slot, the traps provide sufficient open area to let process flow move smoothly thus minimizing pressure loss through the system.,Your resin trap can be designed to suit either new or existing strainer bodies.

Inquiry now

|

Wedge Wire Screen |

|

Vibratory Centrifuge Basket are manufactured using high quality stainless steel wedge wire and carbon steel flanges and frames. The unique centrifuge basket designs combine our specially selected wedge wire profiles with our field proven support frame and stringent manufacturing standards allowing us to produce top quality baskets that work well and are robust.

Inquiry now

|

Wedge Wire Screen |

|

Chip Wringer Oil Screens support cores is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine. Each profile wire and support rod is welded by resistance welding.

Inquiry now

|

Wedge Wire Screen |

|

Looped Wedge Wire is made from round wire which is first looped at regularly pitched intervals and then pressed into a deep wedge shaped section. The loops themselves are pressed so as to produce at each side accurately sized spacing shoulders which butt together when the wires are assembled.

Inquiry now

|

Wedge Wire Screen |

|

Looped Wedge Wire is made from round wire which is first looped at regularly pitched intervals and then pressed into a deep wedge shaped section. The loops themselves are pressed so as to produce at each side accurately sized spacing shoulders which butt together when the wires are assembled

Inquiry now

|

Wedge Wire Screen |

|

TheFish Protection Screens System design utilizes low velocity flow(typically < 1/2 fps) through the wedge wire screen surface which minimizes impingement and danger to aquatic life.,Profile wire fish screens prevent entrainment, injury, or death of the targeted aquatic species by physically precluding fish from entering a water intake.

Inquiry now

|

Wedge Wire Screen |

|

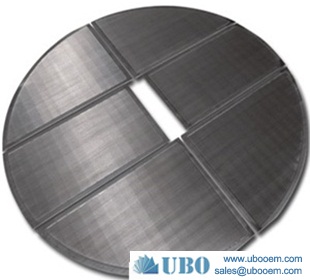

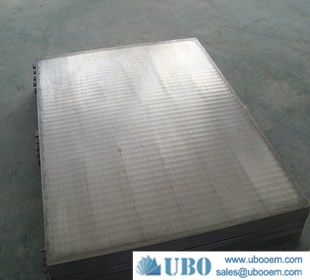

Wedge wire screen support grids offer a relatively flat and smooth surface to reduce degradation of the media in down-flow processes.

Inquiry now

|

Wedge Wire Screen |

|

A wedge wire support grid provides a false bottom in a lauter tun in many breweries. ,The stainless steel wedge wire screen can be made in sections to fit through a man-way. The outside of each section is banded with steel bar and lengths of steel strips are supplied to provide a seal between sections.

Inquiry now

|

Wedge Wire Screen |

|

Collector / Distributor systems are important components of ion exchange units, media filters, sand filters, carbon strip vessels, carbon towers, clay filters, and in many water and wastewater treatment applications.

Inquiry now

|

Wedge Wire Screen |

|

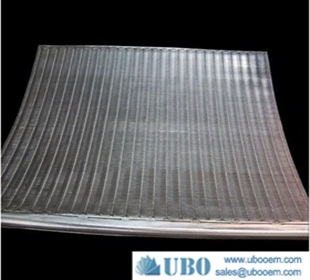

The dewatering capacity of a wedge wire cross-flow sieve panels is primarily influenced by the screen width, the slot opening, and the wire size (width). Installation angle, feed velocity and uniform distribution across the screen are also very important.

Inquiry now

|

Wedge Wire Screen |

|

The dewatering capacity of a wedge wire cross flow sieve bend screen is primarily influenced by the screen width, the slot opening, and the wire size (width). The chart below shows typical dewatering capacities in US gallons per minute (GPM) per foot of screen width.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire cylinders are used as rotary screens, collectors such as screen laterals and nozzles,resin traps, in-line strainers, water intake screens, well screens, as well as many other applications involving liquid / solids separation.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire decking for vibrating conveyors typically use Wedge wire screen with rectangular support rods for increased beam strength. The wire length of the screen is theoretically unlimited and is only usually restrained by handling and shipping concerns.

Inquiry now

|

Wedge Wire Screen |

|

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media in dewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |