| Category: | Sieve Plate Screen |

| Material: | Stainless Steel |

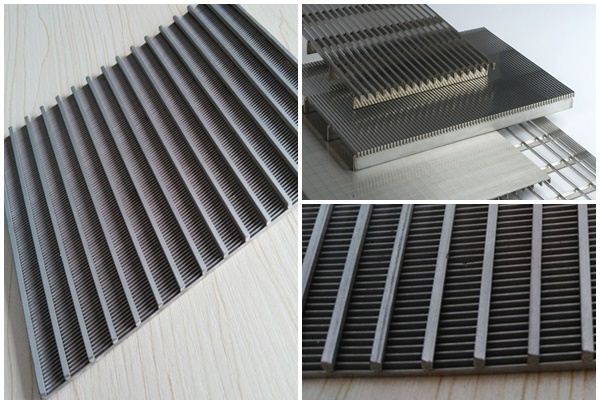

| Properties: | Wedge Wire Screen |

| Application: | Filtration |

Wedge wire decking for vibrating conveyors typically use Wedge wire screen with rectangular support rods for increased beam strength. The wire length of the screen is theoretically unlimited and is only usually restrained by handling and shipping concerns. Custom framing and reinforcing can be added for ease of installation and to meet strength requirements.

UBO supplies wedge wire flat panel for static sieve screening uses. Typical one is the following size with drawings illustrated. Custom sizes and orders are accepted.

The wedge wire is arranged in parallel to form a flat surface. The flat surface is further supported by welding to the steel rod.

-- Avoids clog and ensures an uninterrupted flow.

-- strong structure and high open area

-- Wedge wire screen panels can be constructed using round support rods or rectangular support

rods.

-- can be designed to optimize the open area strength and wear life for each application.

Applications for wedge wire screen panels include cross flow sieves, vibrating screen decking,mineral processing, surface water intake screens, fish diversion screen panels, hatchery screens, food processing, and flooring for malt kiln, germination, and grain drying.

|

Specification |

|

|

Material |

AISI304/316/316L,Galvanized low carton |

|

Wedge Wire(mm) |

Width: 1.50 1.80 2.30 3.00 3.30 3.70 |

|

Height: 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

|

Support rod (mm) |

Width: 2.30 3.00 3.30 3.70 |

|

Height: 2.70 3.60 4.70 5.60 6.30 |

|

|

Round: 2.50mm --6.00mm |

|

|

Slot /opening size |

0.10--6.00mm,also can be customized as your request. |

|

Length /Width |

Can be customized ad your request |

|

Width |

25mm--1200mm |

Package: in wood case

Delivery: 10-20 days