|

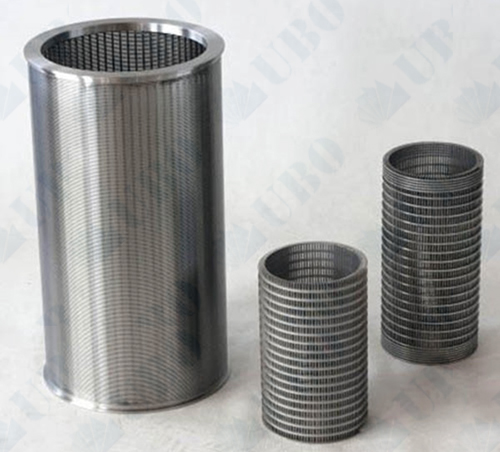

The wedge wire basket is widely used in many industries in screening, filtering, dehydration, mud, and other operations.

Inquiry now

|

Wedge Wire Screen |

|

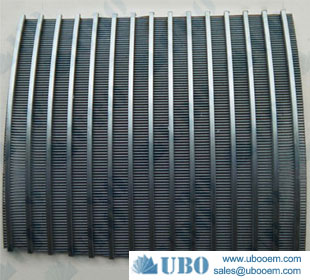

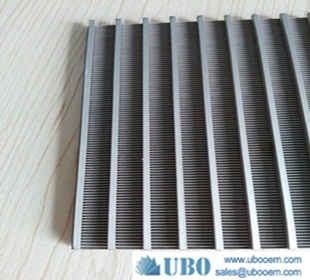

Fetures of wedge wire screen basket:,The wire shape is inverse triangle,it makes the pulp flows out amoothly,and decreases the resistance.

Inquiry now

|

Wedge Wire Screen |

|

High quality and large stock sintered filter, you can learn more details from the description and specifications.

Inquiry now

|

Sintered Filter |

|

pressure screen filters, typically made from perforated plate with hole diameters of less than 0.008 in. / 0.20 mm, can be used to recover fibers in water streams, to remove fibers in water used on the paper machine or in dilution water for the headbox. Using a pressure screen filter eliminates the risk of stringing and of plugging the water nozzles.

Inquiry now

|

Wedge Wire Screen |

|

Ubo offers single- and multi-stage pressure screens, applicable in all screen applications, i.e., recycled fibers, mechanical pulp, chemical pulp, broke screening and machine screen applications.

Inquiry now

|

Wedge Wire Screen |

|

Packaged Treatment Plant is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine. Each profile wire and support rod is welded by resistance welding.

Inquiry now

|

Wedge Wire Screen |

|

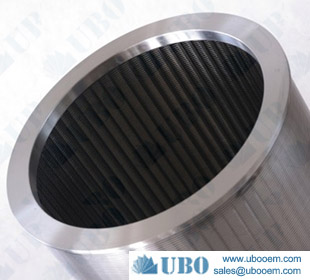

Wedge wire screen drum basket is composed of rod strips and V shaped wires through manufacturing on specialized welding machine.,The rib strips and V shaped wires will be welded by resistance welding, has enough welding strength, equally slot gap, high corrosion resistance, large filter area, good permeability, simple structure,

Inquiry now

|

Wedge Wire Screen |

|

Drum Screens are made from V shaped profile wire, which is spirally wound around a cage of longitudinal support rods.

Inquiry now

|

Wedge Wire Screen |

|

We offer a reliable and efficient range of Stainless Steel Wedge Wire Filter Cartridges. Our offered products are extensively demanded by various industries and are manufactured in accordance with the industry set norms and guidelines. Post-production, we test each product on various stages to give our clients.

Inquiry now

|

Wedge Wire Screen |

|

It is manufactured by a v or wedge shaped wire around an internal array of longitudinal supportrods. Each intersecting point of these wire is fusion welded.

Inquiry now

|

Wedge Wire Screen |

|

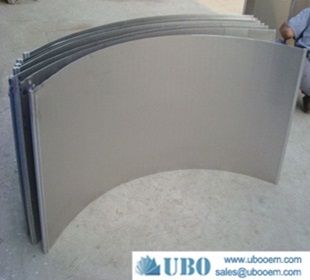

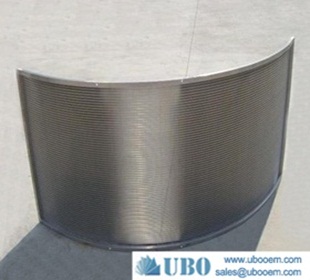

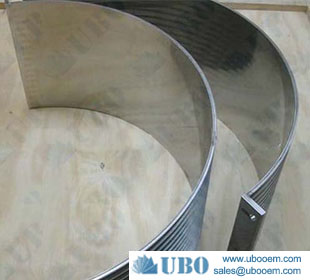

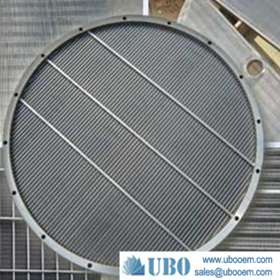

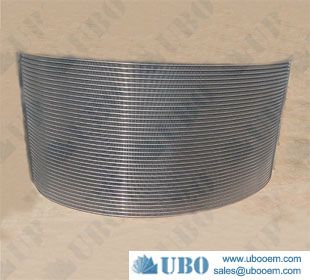

Looped Wire Screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface

Inquiry now

|

Wedge Wire Screen |

|

UBO offers a multitude of screen configurations and sizes for both internally- fed and externally-fed rotary sieve equipment. Screens are used for effluent solids separation and by-product recovery in a wide variety of municipal and industrial waste water and food processing applications.

Inquiry now

|

Wedge Wire Screen |

|

wedge wire In-line Mixers are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Inquiry now

|

Wedge Wire Screen |

|

wedge wire cylindrical strainers are used down stream from ion exchange vessels and serve as a means of minimizing the loss of ion exchange resins. We can design the traps to capture media particles of any size. With the continuous open slot, the traps provide sufficient open area to let process flow move smoothly. Haixing offers a complete range of resin trap styles to suit virtually any application. All are available in a full range of construction materials with a variety of connecting flanges and housings. In vessels using hydrochloric acid for regeneration, the resin trap must be of hastelloy construction.

Inquiry now

|

Wedge Wire Screen |

|

Conical Screens are all custom made. Length, width, shape and spacing of profile wire are engineered to meet your special job requirements. And the individual wire on the working surface of the wedge wire screen or stainless steel screen can be manufactured at various angles to better serve your needs. Our wedge wire screen sieves, baskets, flat panels and cylinders are used in a wide variety of industries to support, beautify, dewater, deslime, drain and rinse, classify wet/dry, strain, filter, dry and cool.

Inquiry now

|

Wedge Wire Screen |

|

Rotary Sieve Screens is easy to penetrate, having good wear-resisting and corrosion resistance. With Trapezoidal cross-section, even gap, stable welding quality, large opening area, long life time, high strength and high load capacity, it can be made into various shapes. The dimensions, wire diameter, slot and frame structure can be customized.

Inquiry now

|

Wedge Wire Screen |

|

Ubo provides dewatering screens for cossette mixers and diffusion towers in sugar beet processing. As the sugar beet travels through the cossette mixers and diffusion towers, the juice is screened through our looped Wedge Wire screens.

Inquiry now

|

Wedge Wire Screen |

|

wedge wire screen support grids are widely used in steel structure platforms, stair treads, sidewalks, drainages and well covers etc. We can design and manufacture standard steel grating and in customized shapes per client's requirements.

Inquiry now

|

Wedge Wire Screen |

|

Nowadays,most important choice for production of paper, improvement of quality of paper, elevation of productivity, and lowering production cost are decided by Steep Tank Screens .Steep Tank Screens to bring your company the best quality and productivity, and satisfactory outcome in lowering production cost. Steep Tank Screens will bring your company the satisfactory quality of paper, productivity and production cost. Wedge wire designed with superior technology makes effective elimination of foreign substances of stronger screen basket, and supply more open areas.

Inquiry now

|

Wedge Wire Screen |

|

Gravity Fed Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.,Gravity Fed Screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Inquiry now

|

Wedge Wire Screen |