|

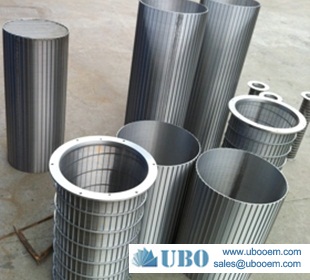

Trapezoidal galvanized V Shaped Wire Water Well Screens is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). It has a structure and high open area, as well as accurate slot dimension.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Screens special consist of V shape profile wire and the longitudinal support rods. Each intersecting point the V shape section plane can avoid blockage, and make sure of the unimpeded water. The consecutive slot have more open area, and it can reduce the speed of the water entering to these wires is fushion welded, so it has studry construction and good mechanical property. Avoid the sand entering the screen under the great pressure, so it can filter sand better. Meanwhile, the slot can change according to the real condition of the earth. if you are interested in our products, please contact us for accurate information.

Inquiry now

|

Wedge Wire Screen |

|

Wrought Stainless Steel Rod Based Wedge Wire Screens,1 Materials ss304,ss304L,ss316,ss316L etc.,2 Excellent anti-corrosion,3 Economical to install

Inquiry now

|

Wedge Wire Screen |

|

Water Well Screens,UBO Water Well Screens are manufactured using our unique computerised machinery

Inquiry now

|

Wedge Wire Screen |

|

Welded Wedge Wire Screens are made up of rods and wire. The rod can be round wire, triangular wire or trapezoid wire. The wire is triangular wire (V-shaped wire). wedge wire water well screen have a structure and high open area, as well as accurate slot dimension. At the same time, water well screens have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

Inquiry now

|

Wedge Wire Screen |

|

The advanced SS continuous wire wrap screen tube technology provides superior weld strength and accurate slot openings. The accurate V shaped wires provide free flow and optimal sand control.,A large number of support rods increases tensile strength and achieves rounder and stronger screens.,The screen jacket is fully pickled and passivated for maximum corrosion resistance.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Screens in Food Processing are used in various food processing applications as well as for the de-watering of waste water in meat, poultry and vegetable processing industries.

Inquiry now

|

Wedge Wire Screen |

|

Chip Wringer Oil Screens,Chip Wringer Oil Screens are used in chip processing centrifuges to separate residual machining fluids (coolants and oils) from metal chip waste (swarf).

Inquiry now

|

Wedge Wire Screen |

|

Wire wrapped screens is manufactured by a V or wedge shaped wire around an internal array of longitudinal support rods. Each intersection point of this wire is fusion welded. The V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water (oil) to enter your well freely in ample quantities while at the same time keeps the majority of sand and gravel out of the well.

Inquiry now

|

Wedge Wire Screen |

|

Industrial Wedge Wire Screens,Material: low carton galvanized steel, stainless steel (304,316) Use: waste water treatment,water well.

Inquiry now

|

Wedge Wire Screen |

|

conical centrifuge screens,We are into supplying a wide range of Pressure Screen Baskets, which is specially designed keeping in mind the requirements of paper industries.

Inquiry now

|

Wedge Wire Screen |

|

Externally-fed drum screens, also called round slot tube. It is made of stainless steel wire, which is the most popular type because of outstanding chemical stability and corrosion resistance. The stainless steel cylindrical wedge wire screensis composed of working profile and support profile. It is produced on an automotive machine. The support profiles is placed on the suit position of the machine, during the surface profiles are spirally wounding, the support profiles are welded onto the surface profiles.

Inquiry now

|

Wedge Wire Screen |

|

Paper Mill Pressure Screens are welded by profile V-wire and support wires,it is also called Wedge Wire Screen. It has large filter area because of big opening,Wedge Wire structure are easy for automatic back washing and avoid pipe blocking.The pressure will be reduced when water flows in for greater filter area,avoid the grains of sand flow in the wedge wire tube in the high pressure conditions,so extend the pipe”s life . Between the same length,diameter and slot size,wedge wire pipe is thrice than bridge filter pipes. Moreover, we have inside perforated metal and wedge wire tube outside filter.

Inquiry now

|

Wedge Wire Screen |

|

The stainless steel water intake screens is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire).It is used for oil well, water well, geothermal well, sewage and industrial wastewater disposal plants, food equipment, liquids filtration,cleaning treatment.

Inquiry now

|

Wedge Wire Screen |

|

The industrial SS screens is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire.The warp is triangular wire (V-shaped wire). V-wire wedge wire screen pipes have a robust structure and large open area, as well as accurate slot dimension.

Inquiry now

|

Wedge Wire Screen |

|

SS302 Wedge Wire flat screens for gravel can be constructed using rectangular support rods or round support rods. They are the most widely used type of wedge wire screens mainly in the mineral processing both for stationery as well as vibratory decks.,SS302 Wedge Wire flat screens for gravel can be designed to optimize the open area, strength and wear life for each application. The panels are either continuously or intermittently welded on the lower side of loop to provide complete rigidity to the panels thus becoming very effective in transmitting the vibrations without mechanical failures.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire sieve bend screen can be manufactured in a variety of widths, arc lengths, apertures or wedge wires to suit the flow rate and material being separated.

Inquiry now

|

Wedge Wire Screen |

|

The industrial SS screens). The Industrial wedge wire wrapped screen have a robust structure and large open area, as well as accurate slot dimension. At the same time, wedge wire screens pipe have many advantages such as heat-resisting, anti-corrosive, good machine capability,long service life, safety and reliability and so on. It can be used in many kinds of medium filtering.

Inquiry now

|

Wedge Wire Screen |

|

UBO is specialized in producing and distributing filter, filter element,polymeric filter,filter strainer,wedge wire screen etc. Welcome to contact us for more information and cooperation.0086-311-83289301

Inquiry now

|

Screen Knowledge |

|

Mechanical bar screen consists of a concave curved profile wire screen (also known as wedge wire / v / vee / wire screen) mounted in a frame with the screen openings perpendicular to the flow. Mechanical bar screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

Inquiry now

|

Wedge Wire Screen |