| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment, water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

The advanced SS continuous wire wrap screen tube technology provides superior weld strength and accurate slot openings. The accurate V-shaped wires provide free flow and optimal sand control.

A large number of support rods increases tensile strength and achieves rounder and stronger screens.

The screen jacket is fully pickled and passivated for maximum corrosion resistance.

-- Used in industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc.

-- Used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by dramatically reducing the load.

-- Used for fiber removal in Starch industry.

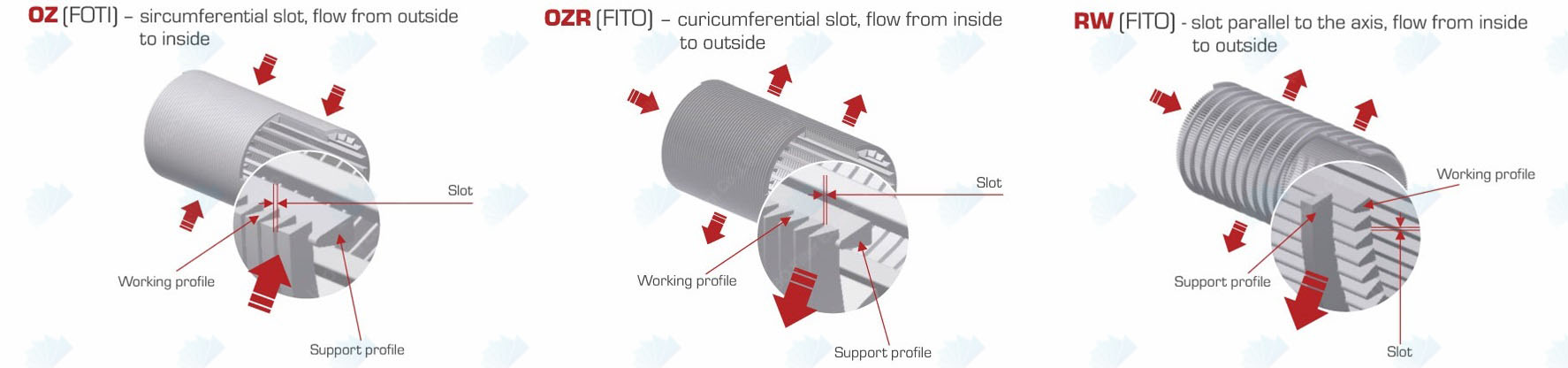

-- A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

-- A “V”shaped profile wire which avoids clogging and ensures an uninterrupted flow.

-- A uniform and efficient well development due to the continuous slot opening.

-- Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

-- Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

|

Size

(inch)

|

O.D

(mm)

|

Slot

(inch)

|

Collapse Strength

(Psi)

|

Tensile Weight

(Ton)

|

Wrap(thick*deep)

(mm)

|

Rods

(mm)

|

|

4

|

117

|

0.04

|

395

|

6

|

2.2*3.0

|

3.8mm/22

|

|

4

|

114.3

|

0.04

|

395

|

6

|

2.3*3.0

|

3.8mm/22

|

|

6

|

168.3

|

0.04

|

252

|

8

|

2.3*3.5

|

3.8mm/32

|

|

8

|

219.1

|

0.01

|

399

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

8

|

219.1

|

0.02

|

370

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

8

|

219.1

|

0.04

|

323

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

10

|

273.1

|

0.01

|

206

|

11

|

3.0*5.0

|

3.8mm/50

|

|

10

|

273.1

|

0.02

|

191

|

11

|

3.0*5.0

|

3.8mm/50

|

|

10

|

273.1

|

0.04

|

167

|

11

|

3.0*5.0

|

3.8mm/50

|