|

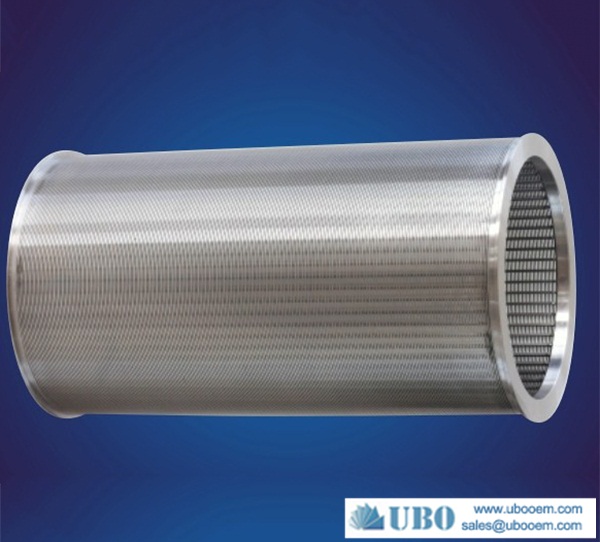

Stainless steel resin traps can be used in water treatment, resin trap, oil field, mining, food industry, chemical industry, paper industry, decoration. YUBO specialized productions of SS resin traps.

Inquiry now

|

Wedge Wire Screen |

|

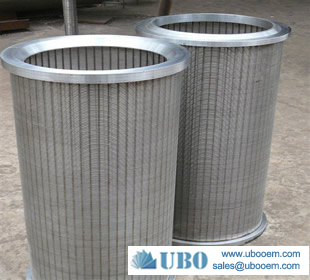

pressure screen filters, typically made from perforated plate with hole diameters of less than 0.008 in. / 0.20 mm, can be used to recover fibers in water streams, to remove fibers in water used on the paper machine or in dilution water for the headbox. Using a pressure screen filter eliminates the risk of stringing and of plugging the water nozzles.

Inquiry now

|

Wedge Wire Screen |

|

Ubo offers single- and multi-stage pressure screens, applicable in all screen applications, i.e., recycled fibers, mechanical pulp, chemical pulp, broke screening and machine screen applications.

Inquiry now

|

Wedge Wire Screen |

|

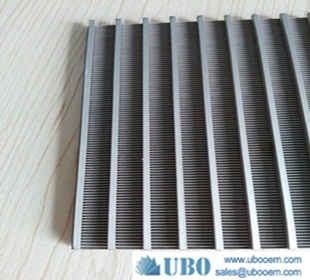

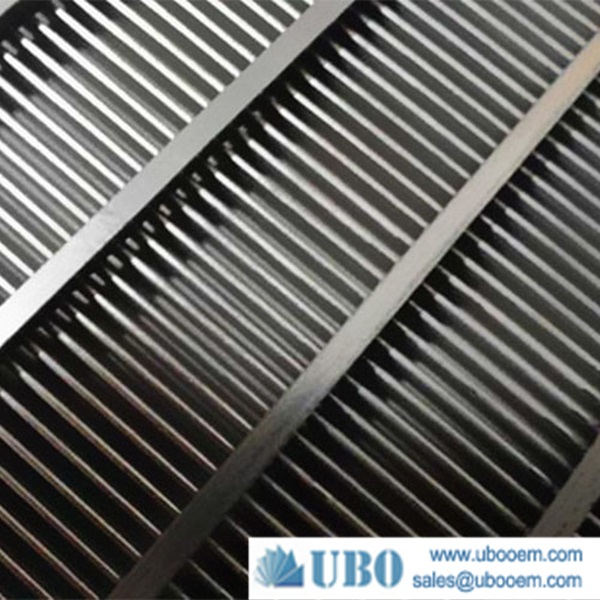

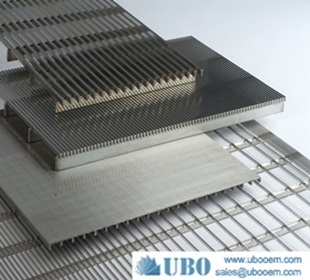

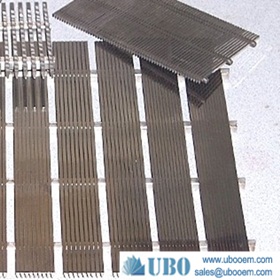

It is manufactured by a v or wedge shaped wire around an internal array of longitudinal supportrods. Each intersecting point of these wire is fusion welded.

Inquiry now

|

Wedge Wire Screen |

|

Ubo provides dewatering screens for cossette mixers and diffusion towers in sugar beet processing. As the sugar beet travels through the cossette mixers and diffusion towers, the juice is screened through our looped Wedge Wire screens.

Inquiry now

|

Wedge Wire Screen |

|

The Passive Intake Screens can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication.

Inquiry now

|

Wedge Wire Screen |

|

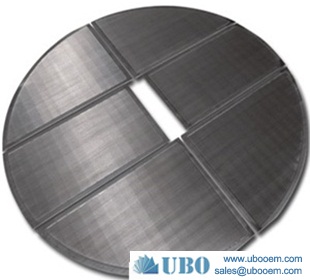

Stainless steel flat wedge screen panel is made of V shaped rod or Convex shape wire with an unique welding process, offering great strength precision ,long service life.

Inquiry now

|

Wedge Wire Screen |

|

Screw presses are used in a wide variety of dewatering applications, often in the same applications as belt presses, centrifuges, and filter presses. The screw press is a simple, slow moving mechanical device. Dewatering is continuous and is accomplished by gravity drainage at the inlet end of the screw and then by reducing the volume as the material being dewatered is conveyed from the inlet to the discharge end of the screw press.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire screen support grids offer a relatively flat and smooth surface to reduce degradation of the media in down-flow processes.

Inquiry now

|

Wedge Wire Screen |

|

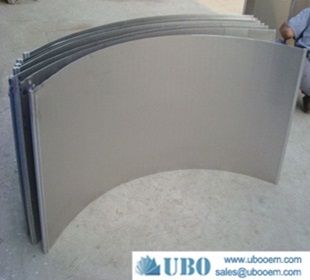

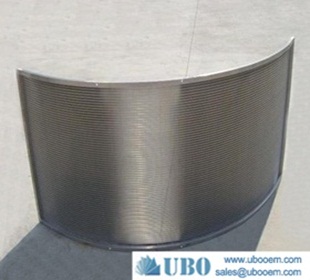

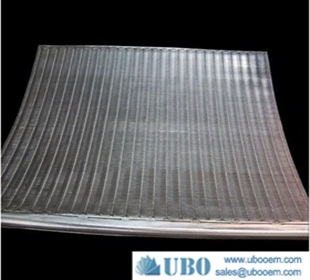

The dewatering capacity of a wedge wire cross-flow sieve panels is primarily influenced by the screen width, the slot opening, and the wire size (width). Installation angle, feed velocity and uniform distribution across the screen are also very important.

Inquiry now

|

Wedge Wire Screen |

|

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media in dewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

Stainless steel Casing pipe & tube are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Inquiry now

|

Wedge Wire Screen |

|

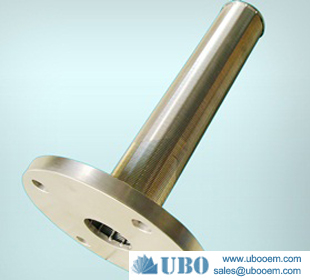

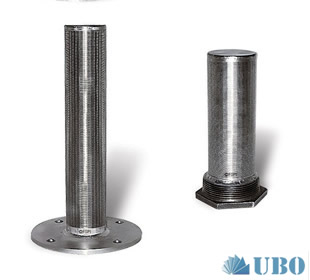

Wedge wire screen resin trap is a safety device used on the outlet pipe lines of ion exchange units, high-purity water systems and activated carbon and media filters.

Inquiry now

|

Wedge Wire Screen |

|

Filter nozzles are used in liquid/solid or gas/solid separation (sand, catalyst, resins, zeolite etc). The design of each nozzle and the exact quantity will be proposed in order to obtain a perfect distribution or collection of flow.

Inquiry now

|

Wedge Wire Screen |

|

stainless steel Water treatment products water filters is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). It has a structure and high open area, as well as accurate slot dimension.

Inquiry now

|

Wedge Wire Screen |

|

stainless steel flat wedge wire screen panel can also be called Wedge Wire screen flat panel, wedge wire sieve bend screen,stainless steel screen plate.,The dewatering capacity of a welded wedge wire screen is primarily influenced by the screen width, the slot opening, and the wire size (width). Installation angle, feed velocity and uniform distribution across the screen are also very important.

Inquiry now

|

Wedge Wire Screen |

|

The Water well screens pipe (V-shaped wire). The welded ring sand control wedge wire screen pipe have a robust structure and large open area, as well as accurate slot dimension. At the same time, wedge wire screens pipe have many advantages such as heat-resisting, anti-corrosive, good machine capability,long service life, safety and reliability and so on. It can be used in many kinds of medium filtering.,

Inquiry now

|

Wedge Wire Screen |

|

This type of wedge wire v shap screen tube is constructed by winding cold rolled triangular V-shaped wire around a circular array of longitudinal rods. the wire is welded to the rods and produces a rigid unit that has high strength and minimum weight.

Inquiry now

|

Wedge Wire Screen |

|

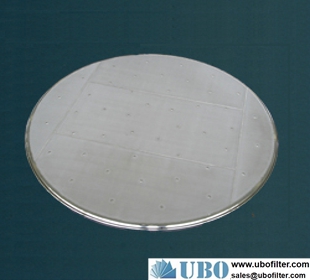

This kind of Stainless Steel Wire Mesh Pressure Leaf Filter are made of muti-layer sintered wire woven mesh.It has good capacicties such as the corrossion resistance,good air permeability,easy to back wash,high filter rating and etc.

Inquiry now

|

Filter Disc |

|

Stainless Steel Wire Mesh Stainless Steel Wire Filter Mesh Wire Cloth,Material:SUS302, 304, 316, 304L, 316L stainless steel wire ,

Inquiry now

|

Filter Disc |