| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Wedge Wire Screen |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

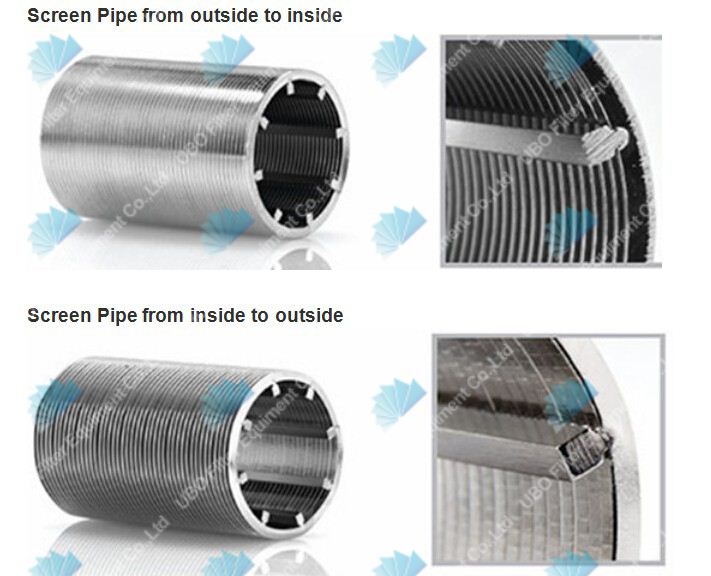

The Water well screens pipe (V-shaped wire). The welded ring sand control wedge wire screen pipe have a robust structure and large open area, as well as accurate slot dimension. At the same time, wedge wire screens pipe have many advantages such as heat-resisting, anti-corrosive, good machine capability,long service life, safety and reliability and so on. It can be used in many kinds of medium filtering.

application in deep well pump to dive the water pump, in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment; the petroleum industry, the petroleum product terminal filters; and the chemical acid, the alkali liquid filters, the ethyl alcohol and the organic solution recycling filters

Advantage of Water Well Screen Stainless Steel Wedge Wire Wedge Wire Screen Tube

·Continuous slot opening significantly increases the available open area, thus providing greater access to the water bearing zone.

· A “V”shaped profile wire avoids clogging and ensures an uninterrupted flow.

· V-wire welded screens have a robust structure and large open area, as well as accurate slot dimension.

· V-wire welded water well screens have the features of easy backwashing, long service life, high safety and reliability and competitive price.

|

Outside Diameter

|

Profile wire

|

Rod wire

|

Rod quantity

|

Slot size

|

Length

|

||

|

DN

|

Inch

|

mm

|

mm

|

mm

|

|

mm

|

mm

|

|

20

|

3/4

|

26.9

|

1.5*2

|

2*3

|

12

|

0.1~0.25

|

45~3000 |

|

25

|

1

|

33.7

|

1.5*2

|

2*3

|

14

|

0.1~0.25

|

45~3000 |

|

32

|

1-1/4

|

42.4

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000 |

|

40

|

1-1/2

|

48.3

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000 |

|

50

|

2

|

60.3

|

1.5*2

|

2*3

|

18

|

0.1~0.5

|

45~3000 |

|

65

|

2-1/23

|

76.1

|

1.5*2

|

2*3

|

20

|

0.1~0.5

|

45~3000 |

|

80

|

3

|

88.9

|

1.8*2.5

|

2*3

|

24

|

0.1~0.5

|

1000~6000 |

|

100

|

4

|

114.3

|

1.8*2.5

|

2*3

|

30

|

0.5~2

|

1000~6000 |

|

125

|

5

|

139.7

|

2.3*2.7

|

2*3

|

36

|

0.5~2

|

1000~6000 |

|

150

|

6

|

168.3

|

2.3*2.7

|

3*5

|

44

|

0.5~2

|

1000~6000 |

|

200

|

8

|

219.1

|

3.3*3.5

|

3*4.7

|

56

|

0.5~2

|

1000~6000 |

|

250

|

10

|

273

|

3.3*3.5

|

4*6

|

66

|

0.5~2

|

1000~6000 |

|

300

|

12

|

323.9

|

3.3*4.7

|

4*6

|

72

|

0.5~2

|

1000~6000 |

|

350

|

14

|

355.6

|

3.7*5

|

4*6

|

80

|

0.5~2

|

1000~6000 |

|

400

|

16

|

406.4

|

1.5*2

|

2*3

|

94

|

0.1*2

|

1000~6000 |

|

450

|

18

|

457

|

2*3

|

4*5

|

112

|

0.1*2

|

500~400 |

|

500

|

20

|

508

|

2*3

|

4*5

|

124

|

0.1*2

|

500~400 |

|

550

|

22

|

559

|

2*3

|

4*5

|

140

|

0.1*2

|

500~400 |

|

600

|

24

|

610

|

2*3

|

4*5

|

156

|

0.1*2

|

500~400 |

|

Siot:0.1mm~2mm Tolerance:0.05 |

|||||||