|

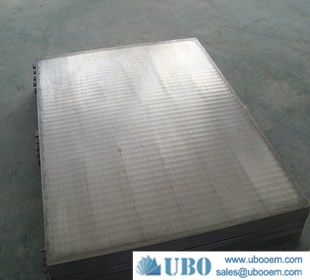

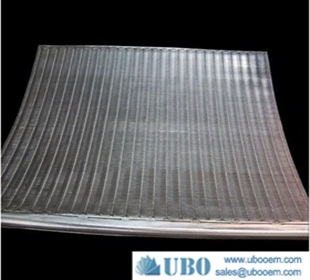

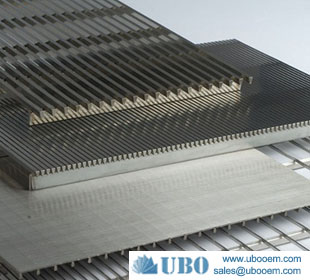

Wedge wire decking for vibrating conveyors typically use Wedge wire screen with rectangular support rods for increased beam strength. The wire length of the screen is theoretically unlimited and is only usually restrained by handling and shipping concerns.

Inquiry now

|

Wedge Wire Screen |

|

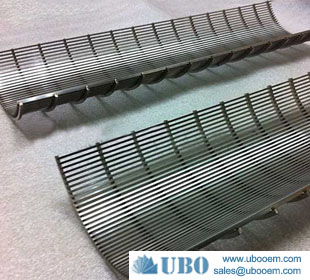

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media in dewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media indewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

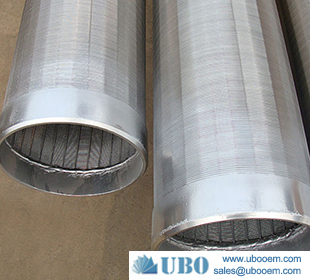

Stainless steel Casing pipe & tube are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Inquiry now

|

Wedge Wire Screen |

|

We produce the proven slip-on type of pipe base screen. Our slip-on type of pipe base screen is manufactured from two components: the base pipe and the slip-on screen. The base pipe, casing or tubing, is selected to API specifications by size, grade and weight for each of your required applications. See Table 3, for our standard range.

Inquiry now

|

Wedge Wire Screen |

|

UBO is specialized in producing and distributing wire mesh, hardware cloth,wire mesh fence,perforated metal etc. Welcome to contact us for more information and cooperation.0086-0318-5183240

Inquiry now

|

Wedge Wire Screen |

|

The V-shaped wire can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen”s construction

Inquiry now

|

Wedge Wire Screen |

|

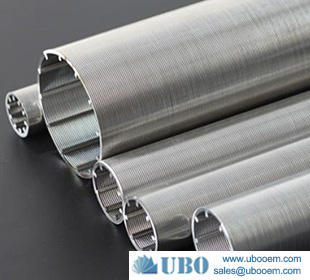

Welded Wedge wire Wedge Wire Screen filter pipe is manufactured by a V or wedge shaped wire around an internal array of longitudinal support rods. Each intersection point of this wire is fusion welded. The V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water (oil) to enter your well freely in ample quantities while at the same time keeps the majority of sand and gravel out of the well.,

Inquiry now

|

Wedge Wire Screen |

|

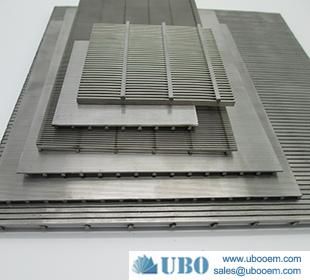

Flat wedge wire screen panel / stainless steel material welded wedge wire screen / flat welded screens in a large variety of surface and support wire combinations, that can be applied for simple screen plates to heavily reinforced reactor internals.

Inquiry now

|

Wedge Wire Screen |

|

They Provide even distribution or collection and avoid flow/pressure concentrations such as dead zones, wall effects or channeling. Hub Laterals can be designed for disc head vessels enabling the system to collect completely to the bottom of the vessel.

Inquiry now

|

Wedge Wire Screen |

|

Filter nozzles are used in liquid/solid or gas/solid separation (sand, catalyst, resins, zeolite etc). The design of each nozzle and the exact quantity will be proposed in order to obtain a perfect distribution or collection of flow.

Inquiry now

|

Wedge Wire Screen |

|

stainless steel Water treatment products water filters is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). It has a structure and high open area, as well as accurate slot dimension.

Inquiry now

|

Wedge Wire Screen |

|

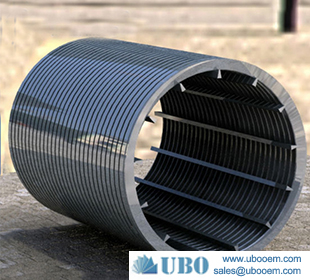

Wedge Wire cylinders are used as rotary screens, collectors such as screen laterals and nozzles, resin traps, in-line strainers,water intake screens, well screens, as well as many other applications involving liquid / solids separation.,

Inquiry now

|

Wedge Wire Screen |

|

Crimped wire screen can withstand the rigorous treatment and survive the day and night attrition experienced in quarries, sand and gravel pits and all types of ore treatment.,Atlas crimped screen is renowned for their extremely high resistance to abrasion. Close checks on raw materials, production processes and constant quality control at all stages of manufacture guarantee a top quality finished product.,

Inquiry now

|

Wedge Wire Screen |

|

Mining screens are used in sorting, classifying, dewatering, scalping, and desliming applications,such as copper, gold, coal, iron ore, platinum, Diamond chrome, mineral sands,silver mine, clay, sandy soil,etc.

Inquiry now

|

Wedge Wire Screen |

|

Welded Wedge Wire Screens are made from V shaped profile wire, which is spirally wound around a cage of longitudinal support rods. Each intersecting point of these wires is fusion welded, with an unique welding process. The pitch of winding gives different spacing between two adjacent turns of wire. This spacing gives passage for water to enter.

Inquiry now

|

Wedge Wire Screen |

|

Run down screens offer a high capacity, cost effective method of solids/liquids separation utilizing stainless steel wedge wire as the screening medium.

Inquiry now

|

Wedge Wire Screen |

|

Vibrating screen consumes big quantity of wedge wire.

Inquiry now

|

Wedge Wire Screen |

|

Stainless steel Wedge Wire oil well screen filter tubes have become the predominant screen type in the water well industry.

Inquiry now

|

Wedge Wire Screen |

|

The warp is triangular wire (V-shaped wire). The welded ring sand control wedge wire screen pipe have a robust structure and large open area, as well as accurate slot dimension.

Inquiry now

|

Wedge Wire Screen |