| Category: | Lauter Tun Screen |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request |

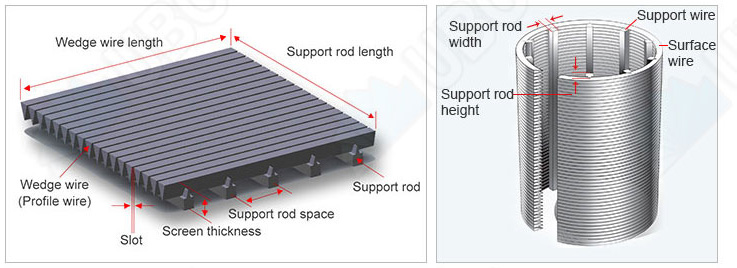

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

wedge wire screen for mining & mineral processing are made from V shaped profile wire, with an unique welding process, offering great strength, precision, long service life and a wide range of applications in the field of process, engineering such as sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals etc.

Wedge wire screens are used in a wide range of architectural situations such as floor grates to cover water run off drains in places such as driveways, car parks, shopping centers or malls. It can also solve the problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals.

1.) Wedge wire screen style isn't easy to be locked

2.) Due to the different pressure between inside from outside,it could be very easily to clean the plugging material.

3.) We are eager for long-terms cooperative parters ,our factory promise the best quality to have a high filtering accuracy, high strengh and durability

4.) We have the most advanced equipments and the most professional workers , so totally could be as per customer's drawing to produce new styles.

1. Non-clogging construction: The V-shape section plane of wedge wire screens (Wedge Wire type screens) creates the continuous slot, which can avoid blockage and make sure of the unimpeded water.

2. Large Filtering Area: The consecutive slot of wedge wire screens (Wedge Wire type screens) have wider open area,

and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can control sand better,

which can increase the water yield and prolong service time of the well.

3.Long service life Wire and support rods are all-welded, which makes wedge wire screens (Wedge Wire types screens) more robust and longer life.

4.Excellent construction strength: The longitudinal support rods and the continuous slot make the wedge wire screens(Wedge Wire type screens) have more excellent pressure-resistant performance.

5.Specifications and end connections of wedge wire screens(Wedge Wire Screens) can me fabricated according to customers’ requirements.

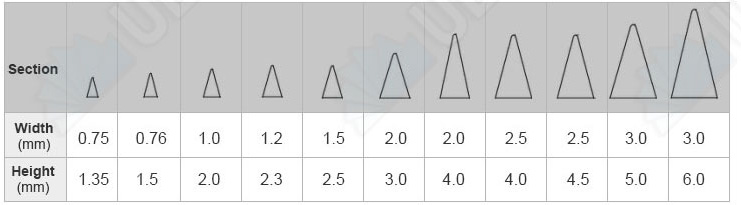

specification (wedge wire ):

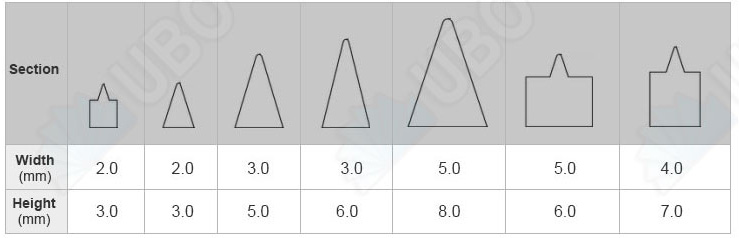

specification (support rod):

Note: this is the normal wire, others could customized

| Outside Diameter | Profile wire | Rod wire | Rod quantity | Slot size | Length | ||

| DN | Inch | mm | mm | mm | mm | mm | |

| 20 | 3/4 | 26.9 | 1.5*2 | 2*3 | 12 | 0.1~0.25 | 45~3000 |

| 25 | 1 | 33.7 | 1.5*2 | 2*3 | 14 | 0.1~0.25 | 45~3000 |

| 32 | 1~1/4 | 42.4 | 1.5*2 | 2*3 | 16 | 0.1~0.25 | 45~3000 |

| 40 | 1~1/2 | 48.3 | 1.5*2 | 2*3 | 16 | 0.1~0.25 | 45~3000 |

| 50 | 2 | 60.3 | 1.5*2 | 2*3 | 18 | 0.1~0.5 | 45~3000 |

| 65 | 2~2/2 | 76.1 | 1.5*2 | 2*3 | 20 | 0.1~0.5 | 45~3000 |

| 80 | 3 | 88.9 | 1.8*2.5 | 2*3 | 24 | 0.1~0.5 | 45~3000 |

| 100 | 4 | 114.3 | 1.8*2.5 | 2*3 | 30 | 0.5~2 | 1000~6000 |

| 125 | 5 | 139.7 | 2.3*2.7 | 2*3 | 36 | 0.5~2 | 1000~6000 |

| 150 | 6 | 168.3 | 2.3*2.7 | 3*5 | 44 | 0.5~2 | 1000~6000 |

| 200 | 8 | 219.1 | 3.3*4.5 | 3*4.7 | 56 | 0.5~2 | 1000~6000 |

| 250 | 10 | 273 | 3.3*4.5 | 4*6 | 66 | 0.5~2 | 1000~6000 |

| 300 | 12 | 323.9 | 3.3*4.7 | 4*6 | 72 | 0.5~2 | 1000~6000 |

| 350 | 14 | 355.6 | 3.7*5 | 4*6 | 80 | 0.5~2 | 1000~6000 |

| 400 | 16 | 406.4 | 1.5*2 | 2*3 | 94 | 0.1~2 | 1000~6000 |

| 450 | 18 | 457 | 2*3 | 4*5 | 112 | 0.1~2 | 500~400 |

| 500 | 20 | 508 | 2*3 | 4*5 | 124 | 0.1~2 | 500~400 |

| 550 | 22 | 559 | 2*3 | 4*5 | 140 | 0.1~2 | 500~400 |

| 600 | 24 | 610 | 2*3 | 4*5 | 156 | 0.1~2 | 500~400 |

| Siot:0.1mm~2mm Tolerance:0.05 | |||||||