| Category: | Water Strainer & Nozzle |

| Material: | stainless steel 304,304L,316,316L,321,430 or as per your request. |

| Properties: | filter nozzle |

| Application: | water-treatment,beer brewing,water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant, refining & petrochemical |

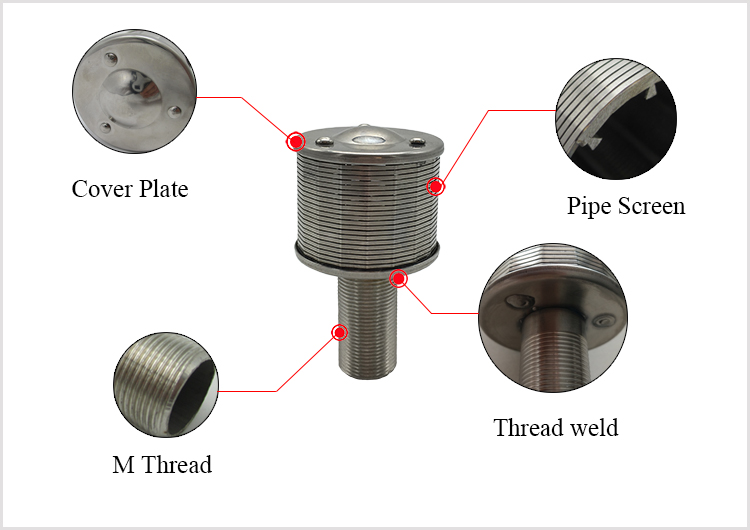

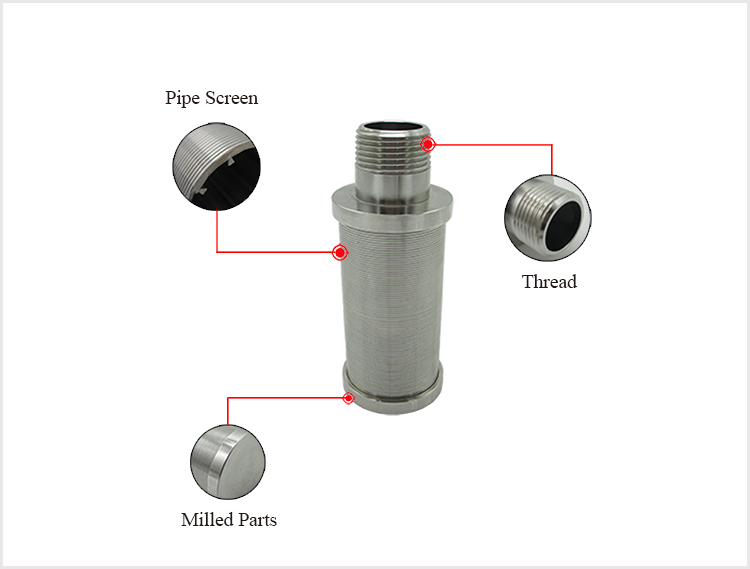

Wedge Wire Screen water filter nozzle strainers are wedge wire structure, in order to make the slot v-shaped.It can stop the impurities very well. Wedge Wire Screen water filter nozzle strainer, have many called, for example, strainer nozzle, stainless steel filter nozzle, header lateral, stainless steel lateral arm, water &gas Strainers.

The wedge wire was welded on the support wire well-proportioned and have perfect roundness. Ensure the screen have bigger filter area and non obstructive, avoid the high concentration of impurities

After work for a period of time, the filter can be back flush.It can use for many times.

Filtering direction from outside to inside (FOTI)

1) Type 316L stainless steel construction.

2) Continuous slot design provide large circulation area

3) Standard nozzle are 2in/51mm diameter and can be attached to the plate either with threaded end fittings or "L" blots.

4) Standard slot opening is typically range between 0.006”(0.15mm), and 0.020in./0.50mm wide suitable for 40 to 50 mesh size media, Other slot sizes are also available.

5) Wedge wire screen is highly resistant to plugging.

6) Choice of either 3/4” NPT or 1” NPT fittings are available from stock. Other styles, such as tee-bolt mountings, and drop tubes are readily available.

7) Unaffected by temperature, corrosion resistant, aging resistant, long life span, easy change, saftey and enviormental friendly.

AISI 304 Wedge Wire water filter screen nozzles are used in liquid/solid or gas/solid separation. Their design and quantity will vary depending on application and customer-flow requirements. Scree Nozzles allow a more effective use of the treatment media.

YUBO WEDGE-FLOW nozzles have distinct advantages in that they are economical, non-clogging and ideally suited as collectors and distributors. The most common standard nozzle is style "N" as shown.

They are efficient and easily installed in false bottom installations with lateral systems. Standard "T" bolt, coupling and custom design connections are equally available. We will provide complete engineering assistance in the design and selection of nozzle internal systems.

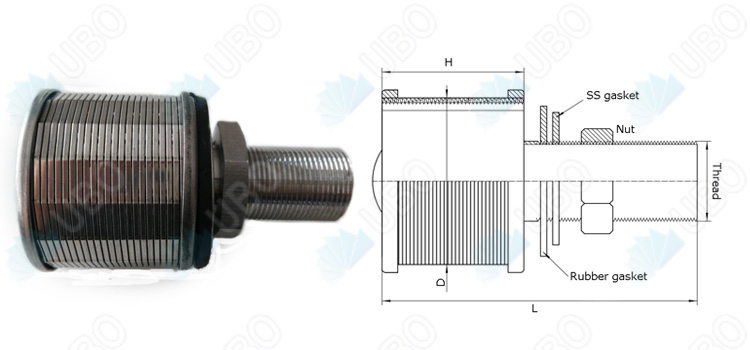

|

|||||||

| Type |

Slot (mm) |

Dimension |

Flow Rating (M3/H) |

||||

| D(mm) | H(MM) | L(MM) | Thread | Fittings | |||

| YUBO-0.5 | 0.25 | 45 | 45 | 90/request | M,NPT, G, PT(BSPT),Z,BSP, request |

SS Gasket, Rubber gasket, Nut, request |

0.5 |

| YUBO-1.0 | 0.25 | 53 | 45 | 90/request | 1.0 | ||

| YUBO-1.5 | 0.25 | 57 | 45 | 90/request | 1.5 | ||

| YUBO-2.0 | 0.25 | 57 | 55 | 100/request | 2.0 | ||

| YUBO-2.5 | 0.25 | 70 | 55 | 100/request | 2.5 | ||

| YUBO-3.0 | 0.25 | 70 | 70 | 120/request | 3.0 | ||

| Note |

* All the above size are the normal size. Customized size is possible. * YUBO could help to design according to the application and requirement. * The nozzles customized range as below: 1. Slot range: 0.05-2mm 2. Dimension: Diameter, Screen Height, Length could produce according to actual requirement and application 3. Thread according to requirement |

||||||

Package: in wood case

Delivery: 10-20 days