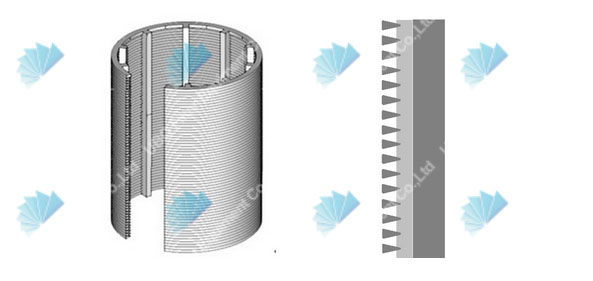

| Category: | Wedge Wire Screen Cylinders |

| Material: | 316 stainless steel |

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

316 Wedge Filter Elements are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Wedge wire screen filter elements are widely used for water, oil and gas wells in the world. As China chief manufacturer and exporter, we export good quality water well screen to many countries. Main products cover bridge slot screen, wire wrapped well screen, stainless steel Wedge Wire Screen, water well screen, wedge wire screen, sieve bend screen, Wedge Wire tube and sand control screen. In addition, we also offer perforated pipes and base pipes for well screen and Wedge Wire Screen.

A continuous slot opening which significantly increases the available open area, thus providing a greater access to the water bearing zone.

A 'V' shaped profile wire which avoids clogging and ensures uninterrupted flow.

A uniform and efficient well development due to the continuous slot opening

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |