|

Stainless Steel V Shaped Wire Screens,Material: low carton galvanized steel, stainless steel (304,316) Use: waste water treatment,water well.

Inquiry now

|

Wedge Wire Screen |

|

Wire wrapped stainless steel wedge wire screen meshs are made up of rods and wire. The rod can be round wire, triangular wire or trapezoid wire. The wire is triangular wire (V-shaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time, water well screens have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

Inquiry now

|

Wedge Wire Screen |

|

The sieve screen basket liners which require external supports and also self-supporting balanced baskets for the centrifuge manufacturers. These wedge wire screen baskets are more complex than the other types of screens requiring extra strength to withstand the stresses of centrifuge dryers. These baskets are typically used in mineral processing for coal, potash, salt, sand, pulp,paper and a variety of chemicals. They are also used for refuse removal from oil and gas drillers.

Inquiry now

|

Wedge Wire Screen |

|

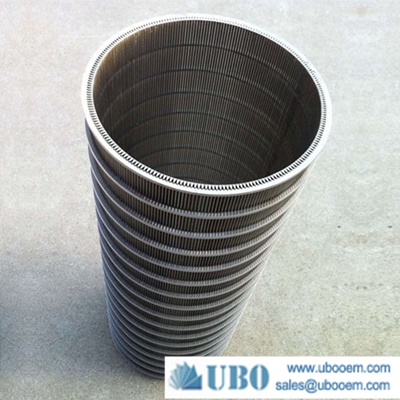

Stainless steel cylindrical wedge wire screens, also called round slot tube. It is made of stainless steel wire, which is the most popular type because of outstanding chemical stability and corrosion resistance. The stainless steel cylindrical wedge wire screensis composed of working profile and support profile. It is produced on an automotive machine. The support profiles is placed on the suit position of the machine, during the surface profiles are spirally wounding, the support profiles are welded onto the surface profiles

Inquiry now

|

Wedge Wire Screen |

|

reverse rolled screen ,Material: Low carton, low carton galvanized steel (LCG), steel treated with plastic,

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire screen are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Inquiry now

|

Wedge Wire Screen |

|

Stainiess steel strainer nozzle is composed of V-profile wire stainless steel which is spirally wrapped in certain equal slot. To maintain the slot size around inside and add extra strength are mounted. It has each cover for both ends of nozzle.Each wire and rod are made by spot welding. and fitting pipe is adjusted according to the thickness of set bottom plate.Nozzle is completed by welding fitting pipe to a cover of down end after setting screw according to the type of nut.

Inquiry now

|

Wedge Wire Screen |

|

Stainless steel filter nozzles manufactured by wrapping a shaped wire around an internal array of longitudinal rods.The wire and rod, generally made from carbon or stainless steel are joined by resistance welding. Screen sections are usually twenty feet long. Commonly referred to as continuous slot or wire wrap screen, this product was originally developed to overcome problems associated with cable tool wells drilled in fine grained.

Inquiry now

|

Wedge Wire Screen |

|

Water wedge wire screen filter nozzle is composed of V-profile wire stainless steel which is spirally wrapped in certain equal slot. To maintain the slot size around inside and add extra strength are mounted. It has each cover for both ends of nozzle.Each wire and rod are made by spot welding. and fitting pipe is adjusted according to the thickness of set bottom plate.Nozzle is completed by welding fitting pipe to a cover of down end after setting screw according to the type of nut.

Inquiry now

|

Wedge Wire Screen |

|

The Wedge Wedge Wire filter nozzle suppliers have a screen pipe. Nozzles are closed on one side and have a threaded fitting on the other. The screen nozzle with thread coupling can be fixed on the filtering equipment for the filteration of water petrol resin and other medium.One rubber shim , one steel shim and two thin nuts of the same material for a nozzle.,

Inquiry now

|

Wedge Wire Screen |

|

Cross flow sieve bend screen are used for making animal feed,filteration,dehydration

Inquiry now

|

Wedge Wire Screen |

|

ubo”s Welded Wedge Wire Screens provide a unique combination of the most important features required for maximum screening efficiency.The product is custom designed to suit the specific requirements of the customer and to enable a relatively low cost and high performance solution for the screening application. The high open area of the Wedge Wire screen provides excellent capacity. Wedge Wire screen offers continuous slot openings that widen inwardly so that particles tend to pass

Inquiry now

|

Wedge Wire Screen |

|

Ubo is specialized in producing and distributing stainless steel filter elements,filter element, filter disc, sintered filter,filter strainer,polymeric filter,basket filter, wire mesh filter,wedge wire screen,Welcome to contact us for more information and cooperation.0086-0311-83289301

Inquiry now

|

Filter Disc |

|

Ubo is specialized in producing and distributing stainless steel filter elements,filter element, filter disc, sintered filter,filter strainer,polymeric filter,basket filter, wire mesh filter,wedge wire screen,Welcome to contact us for more information and cooperation.0086-0311-83289301

Inquiry now

|

Filter Disc |

|

Ubo is specialized in producing and distributing stainless steel filter elements,filter element, filter disc, sintered filter,filter strainer,polymeric filter,basket filter, wire mesh filter,wedge wire screen,Welcome to contact us for more information and cooperation.0086-0311-83289301

Inquiry now

|

Filter Disc |

|

Wedge wire run down screen systems range of Screentex run down screens offer a high capacity, cost effective, highly efficient method of solids/liquids separation utilising stainless steel wedge wire as the screening medium.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire sieve bend screen is widely used in mining, coaling,food,etc.

Inquiry now

|

Wedge Wire Screen |

|

Slotted wedge wire screens,the production of slotted wedge wire screens is based on electric resistance welding method through welding of specially profiled wires to carrying wires at 90 angle. They are characterized by precision workmanship and gap size. They can carry big loads and have high open surface ratio. Low susceptibility to blindness and ideally smooth surface. The newest welding technology allows using different working wires, different gaps between carrying wires in one screen, different carrying wires and different distances between them.

Inquiry now

|

Wedge Wire Screen |

|

stainless steel wedge wire screen grilles for ventilation is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine, then be made to screen panel through cutting and edge welding. Each profile wire and support rod is welded by resistance welding.

Inquiry now

|

Wedge Wire Screen |

|

Stainless steel Flat wedge screen panel is made of SS Support V shaped rod or Convex shape wire with an unique welding process, offering great strength precision,long service life. The Screen have a perfectly flat and smooth surface with rectangular openings, also named flat wedge wire screen,flat wedge wire screen panel or wedge wire.

Inquiry now

|

Wedge Wire Screen |