| Category: | Sieve Plate Screen |

| Material: | Stainless steel 316L |

| Properties: | sieve plate screen |

| Application: | Filtration |

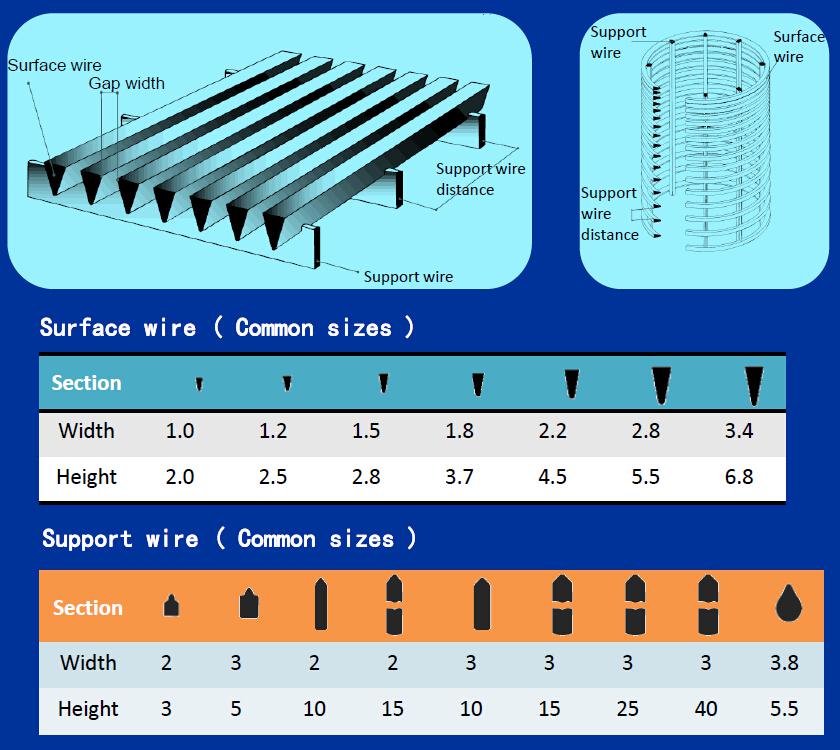

Slotted wedge wire screens ,the production of slotted wedge wire screens is based on electric resistance welding method through welding of specially profiled wires to carrying wires at 90 angle. They are characterized by precision workmanship and gap size. They can carry big loads and have high open surface ratio. Low susceptibility to blindness and ideally smooth surface. The newest welding technology allows using different working wires, different gaps between carrying wires in one screen, different carrying wires and different distances between them.

SS wedge wire sieve screen have a high open area by comparison with woven wire screen media. Supplied in mainly flat forms or curved panel forms. High opening screen gives lower entrance velocities and higher flow rates through the screen. In the case of pump in-taking screens, pumping costs are lower.

Accurate slot gap, high efficiency performance, stable structure, anti-high temperature, anti-corrosive, good mechanical properties, long-lasting and durable, safe and reliable, various field can be applied.

Wedge wire sieve screen can be parts of deep well pumps or submersible pumps; can be used for water treatment equipment, environment protection, the sea water desalination, water softening treatment, oil and chemical processing; terminal filtration for petroleum products, filtration for chemical acid and soda liquid, for alcohol and other organic solvents recycle filtration.

Slot Size (mm): 0.025mm 0.10, 0.15, 0.2, 0.25, 0.30-3mm

Open area: up to 60%

Material: low carbon, low carbon galvanized steel (LCG) steel , stainless steel (304 etc.) Lengths up to 6 meters

Diameter: ranging from 25 to 800mm

End connection: plain beveled ends for butt welding or threaded

Material: Low Carbon Galvanized ( LCG ) and Stainless Steel (SS)

Slot (mm): 0.025 0.1, 0.25, 0.50, 0.75, 1.00, 1.50, 2.00, 3.00 and so on.