|

pressure screen filters, typically made from perforated plate with hole diameters of less than 0.008 in. / 0.20 mm, can be used to recover fibers in water streams, to remove fibers in water used on the paper machine or in dilution water for the headbox. Using a pressure screen filter eliminates the risk of stringing and of plugging the water nozzles.

Inquiry now

|

Wedge Wire Screen |

|

Ubo offers single- and multi-stage pressure screens, applicable in all screen applications, i.e., recycled fibers, mechanical pulp, chemical pulp, broke screening and machine screen applications.

Inquiry now

|

Wedge Wire Screen |

|

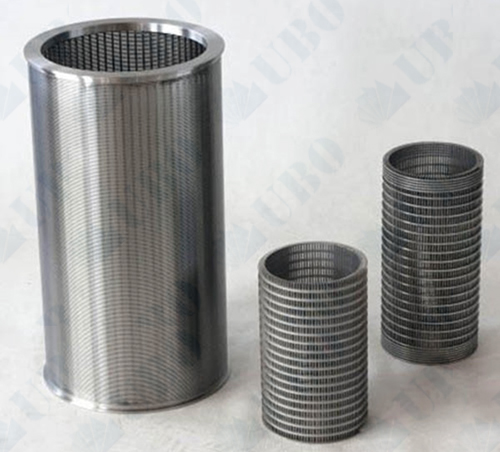

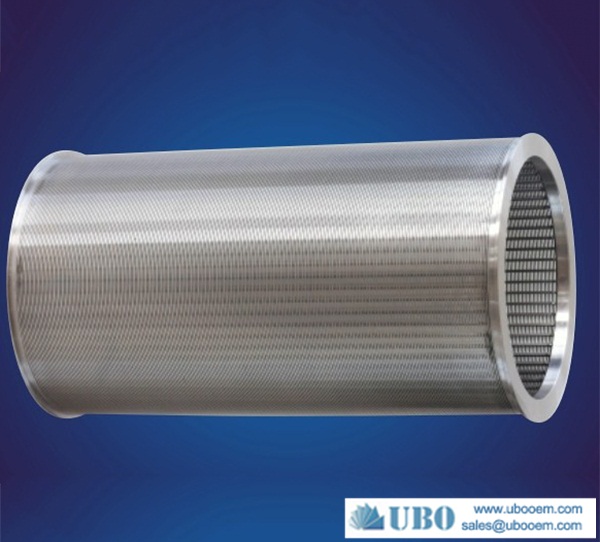

Drum Screens are made from V shaped profile wire, which is spirally wound around a cage of longitudinal support rods.

Inquiry now

|

Wedge Wire Screen |

|

We offer a reliable and efficient range of Stainless Steel Wedge Wire Filter Cartridges. Our offered products are extensively demanded by various industries and are manufactured in accordance with the industry set norms and guidelines. Post-production, we test each product on various stages to give our clients.

Inquiry now

|

Wedge Wire Screen |

|

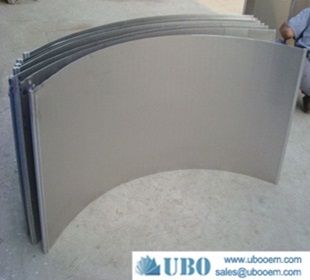

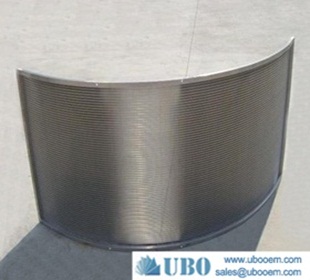

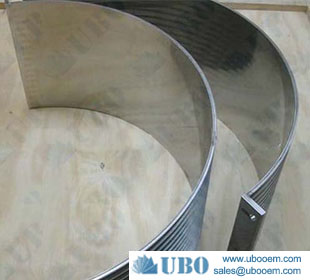

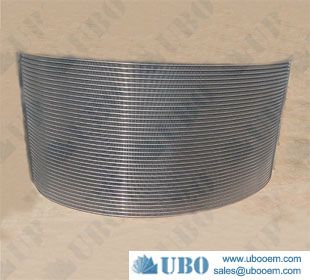

Looped Wire Screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface

Inquiry now

|

Wedge Wire Screen |

|

UBO offers a multitude of screen configurations and sizes for both internally- fed and externally-fed rotary sieve equipment. Screens are used for effluent solids separation and by-product recovery in a wide variety of municipal and industrial waste water and food processing applications.

Inquiry now

|

Wedge Wire Screen |

|

Conical Screens are all custom made. Length, width, shape and spacing of profile wire are engineered to meet your special job requirements. And the individual wire on the working surface of the wedge wire screen or stainless steel screen can be manufactured at various angles to better serve your needs. Our wedge wire screen sieves, baskets, flat panels and cylinders are used in a wide variety of industries to support, beautify, dewater, deslime, drain and rinse, classify wet/dry, strain, filter, dry and cool.

Inquiry now

|

Wedge Wire Screen |

|

Rotary Sieve Screens is easy to penetrate, having good wear-resisting and corrosion resistance. With Trapezoidal cross-section, even gap, stable welding quality, large opening area, long life time, high strength and high load capacity, it can be made into various shapes. The dimensions, wire diameter, slot and frame structure can be customized.

Inquiry now

|

Wedge Wire Screen |

|

Ubo provides dewatering screens for cossette mixers and diffusion towers in sugar beet processing. As the sugar beet travels through the cossette mixers and diffusion towers, the juice is screened through our looped Wedge Wire screens.

Inquiry now

|

Wedge Wire Screen |

|

Nowadays,most important choice for production of paper, improvement of quality of paper, elevation of productivity, and lowering production cost are decided by Steep Tank Screens .Steep Tank Screens to bring your company the best quality and productivity, and satisfactory outcome in lowering production cost. Steep Tank Screens will bring your company the satisfactory quality of paper, productivity and production cost. Wedge wire designed with superior technology makes effective elimination of foreign substances of stronger screen basket, and supply more open areas.

Inquiry now

|

Wedge Wire Screen |

|

The Passive Intake Screens can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication.

Inquiry now

|

Wedge Wire Screen |

|

Gravity Fed Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.,Gravity Fed Screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Inquiry now

|

Wedge Wire Screen |

|

The dewatering capacity of a Wedge Flapper Screens is primarily influenced by the screen width, the slot opening, and the wire size. Installation angle, feed velocity and uniform distribution across the screen are also very important.

Inquiry now

|

Wedge Wire Screen |

|

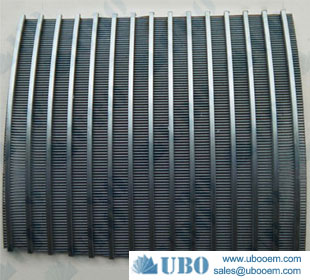

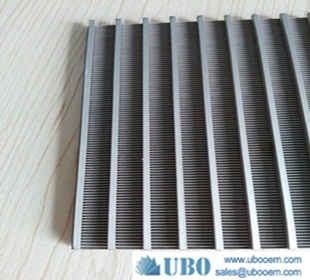

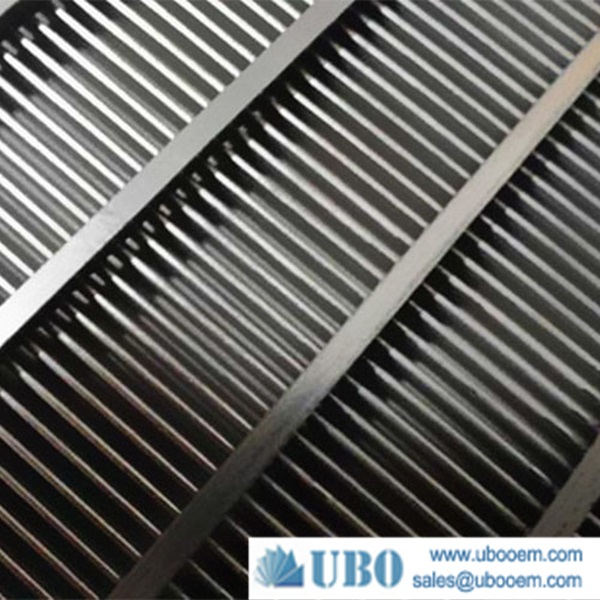

Stainless steel flat wedge screen panel is made of V shaped rod or Convex shape wire with an unique welding process, offering great strength precision ,long service life.

Inquiry now

|

Wedge Wire Screen |

|

Fine mesh woven wire cloth is used in thousands of applications requiring small particle size screening, sorting, sieving, classifying, sizing and separating. Fine mesh screens may be provided complete with screen-edge treatments.

Inquiry now

|

Wedge Wire Screen |

|

Fully welded Wedge Wire flat screens are used for dewatering, sizing, media recovery, and classification. Rigid flat panels are resistance-welded at every wire and support rod juncture.

Inquiry now

|

Wedge Wire Screen |

|

Ubo centrifugal screen baskets are the strongest and most robust in the mineral processing industry. The baskets are built to exacting specifications and quality standards. There are models to suit most centrifugal dryers. Screen wires are welded to support rods at every junction to ensure strong, rigid construction.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Screens column covers are made of SS V shaped and SS V shaped or SS V shaped and SS rod or SS V shaped and SS Convex shaped rod with the unique computer controlled machinery in which a continuous length of profile wire of a triangular section is fusion welded into support rods. This V shaped profile wire is wound around the support rods over the full length of the screen thus creating a continuous slot opening.

Inquiry now

|

Wedge Wire Screen |

|

Profile wire Screens consist of V-shape profile wire and the longitudinal support rods. each intersecting point of these wires is fusion welded. So Profile wire Screens has sturdy constriction and good mechanical property. The V-shape section plane can avoid blockage, and make sure of the unimpeded water. The continuous slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so Profile wire Screens can filter sand better. Meanwhile ,the slot size can be changed according to the real condition of the customer requirements

Inquiry now

|

Wedge Wire Screen |

|

stainless steel static wedge wire screen panels for ventilation is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine, then be made to screen panel through cutting and edge welding. Each profile wire and support rod is welded by resistance welding.,

Inquiry now

|

Wedge Wire Screen |