|

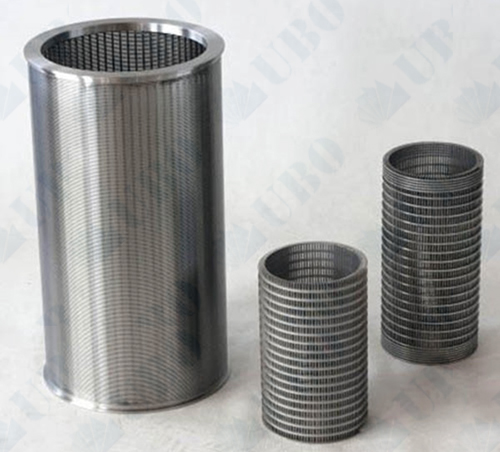

UBO offers a multitude of screen configurations and sizes for both internally- fed and externally-fed rotary sieve equipment. Screens are used for effluent solids separation and by-product recovery in a wide variety of municipal and industrial waste water and food processing applications.

Inquiry now

|

Wedge Wire Screen |

|

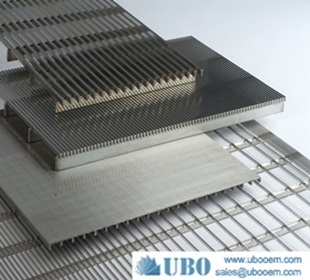

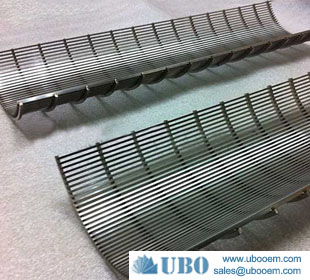

Rotary Sieve Screens is easy to penetrate, having good wear-resisting and corrosion resistance. With Trapezoidal cross-section, even gap, stable welding quality, large opening area, long life time, high strength and high load capacity, it can be made into various shapes. The dimensions, wire diameter, slot and frame structure can be customized.

Inquiry now

|

Wedge Wire Screen |

|

The Passive Intake Screens can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication.

Inquiry now

|

Wedge Wire Screen |

|

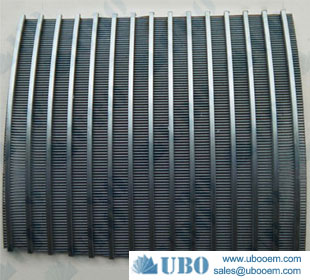

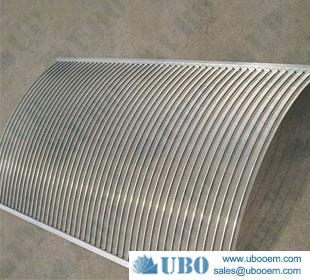

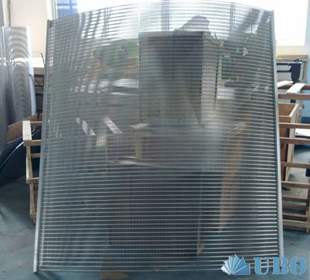

Gravity Fed Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.,Gravity Fed Screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Inquiry now

|

Wedge Wire Screen |

|

gravity fed boxes are typically applied to make The gravity fed boxes are typically applied to make coarse separations ahead of the degerminators and in multistage germ washing. The system uses a Wedge Wire dewatering screen to retain the solids while allowing effluent to run through the system. The slurry is gravity fed to the head box and flows to the screen. The solids retained from the screen gather for disposal or reuse.

Inquiry now

|

Wedge Wire Screen |

|

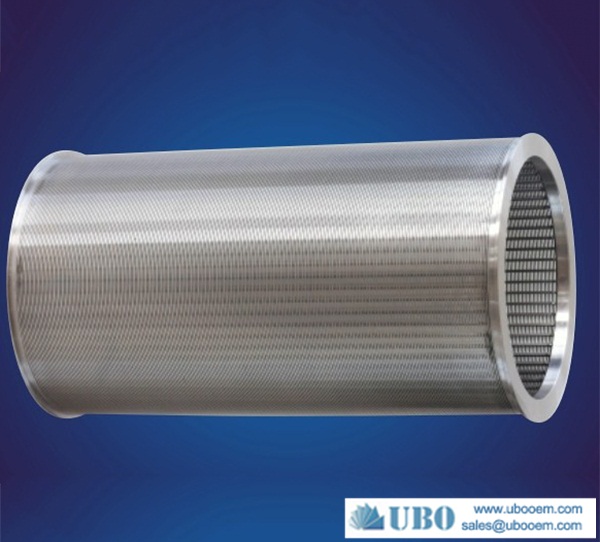

Wedge Wire Screening Systems is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Screens column covers are made of SS V shaped and SS V shaped or SS V shaped and SS rod or SS V shaped and SS Convex shaped rod with the unique computer controlled machinery in which a continuous length of profile wire of a triangular section is fusion welded into support rods. This V shaped profile wire is wound around the support rods over the full length of the screen thus creating a continuous slot opening.

Inquiry now

|

Wedge Wire Screen |

|

Vibrating Screen Panels consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

Inquiry now

|

Wedge Wire Screen |

|

Deep arch Sieve Screens is manufactured by a V or wedge shaped wire around an internal array of longitudinal support rods. Each intersection point of this wire is fusion welded. The V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening

Inquiry now

|

Wedge Wire Screen |

|

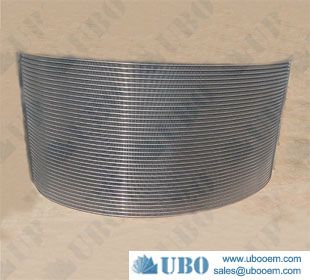

The fine wire sieve bend screen, also known as the wedge wire run down screen, wedge wire side hill screen, DSM screen, Parabolic screen, wedge wire curve screen and so on. The sever bend screen could be custom made and designed according to the application. They are usually used to separate solids from liquids. The curved screen of sieve bend provides greater capacity than flat wedge wire screen due to increased gravitaonal forces on material frowing against the curve.

Inquiry now

|

Wedge Wire Screen |

|

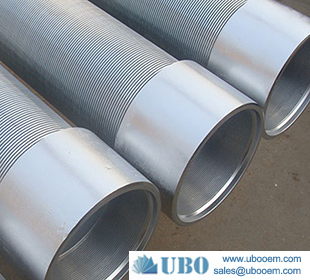

SS Wedge Wire v wire wrapped water well screen tube (V-shaped wire). The Industrial wedge wire wrapped screen have a robust structure and large open area, as well as accurate slot dimension. At the same time, wedge wire screens pipe have many advantages such as heat-resisting, anti-corrosive, good machine capability,long service life, safety and reliability and so on. It can be used in many kinds of medium filtering.,

Inquiry now

|

Wedge Wire Screen |

|

Vibratory Centrifuge Basket are manufactured using high quality stainless steel wedge wire and carbon steel flanges and frames. The unique centrifuge basket designs combine our specially selected wedge wire profiles with our field proven support frame and stringent manufacturing standards allowing us to produce top quality baskets that work well and are robust.

Inquiry now

|

Wedge Wire Screen |

|

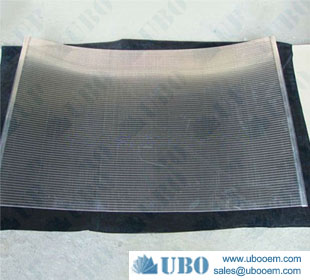

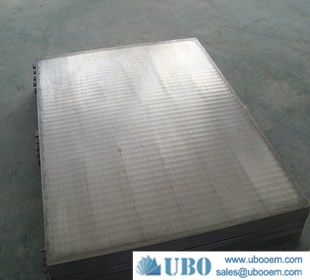

The dewatering capacity of a wedge wire cross-flow sieve panels is primarily influenced by the screen width, the slot opening, and the wire size (width). Installation angle, feed velocity and uniform distribution across the screen are also very important.

Inquiry now

|

Wedge Wire Screen |

|

The dewatering capacity of a wedge wire cross flow sieve bend screen is primarily influenced by the screen width, the slot opening, and the wire size (width). The chart below shows typical dewatering capacities in US gallons per minute (GPM) per foot of screen width.

Inquiry now

|

Wedge Wire Screen |

|

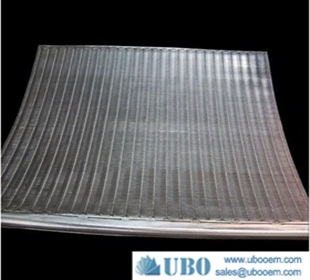

Wedge wire decking for vibrating conveyors typically use Wedge wire screen with rectangular support rods for increased beam strength. The wire length of the screen is theoretically unlimited and is only usually restrained by handling and shipping concerns.

Inquiry now

|

Wedge Wire Screen |

|

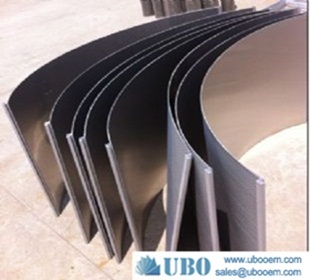

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media in dewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media indewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

The revolutionary reverse rolled wedge wire straining element is extremely rugged and more clog-resistant than conventional strainer elements that use perforated plate or wire mesh screens.This proven state-of-the-art

Inquiry now

|

Wedge Wire Screen |

|

stainless steel Water treatment products water filters is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). It has a structure and high open area, as well as accurate slot dimension.

Inquiry now

|

Wedge Wire Screen |

|

Crimped wire screen can withstand the rigorous treatment and survive the day and night attrition experienced in quarries, sand and gravel pits and all types of ore treatment.,Atlas crimped screen is renowned for their extremely high resistance to abrasion. Close checks on raw materials, production processes and constant quality control at all stages of manufacture guarantee a top quality finished product.,

Inquiry now

|

Wedge Wire Screen |