|

Header lateral distributor is widely used in the under draining applications with the features of effective filtering and screening performance.

Inquiry now

|

Wedge Wire Screen |

|

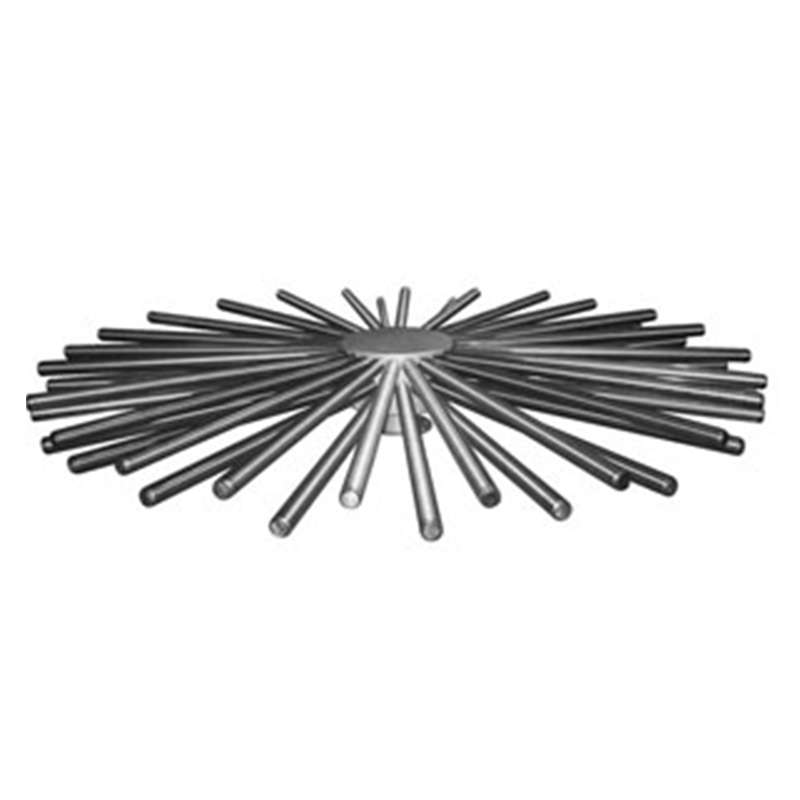

Wedge wire lateral assemblies, also called Wedge Wire Hub and Header Laterals, are assemblies of horizontal herring bone style wedge wire screen laterals and vertically secured round hubs.

Inquiry now

|

News&Trends |

|

Header-Lateral System For the treatment of process water such as in ‘Ion Exchange’ and in the process of removing organic matter.

Inquiry now

|

News&Trends |

|

Each of our Header and Hub-Lateral Systems are carefully designed from your specified design conditions that includes the vessel inside diameter, volumetric flow rate, allowable pressure drop through the screen, resin/media to be retained and minimum open area to list.

Inquiry now

|

News&Trends |

|

Each header lateral consists of a series of screen laterals connected to a central header. Header laterals screen can be used to either distribute inflow or collect flow, depending on their location within a vessel.

Inquiry now

|

News&Trends |

|

wedge wire screen, Lateral Water Distributor, Header-Lateral

Inquiry now

|

News&Trends |

|

The wedge wire hub lateral water distributor is designed for industrial or commercial water treatment and wastewater treatment systems.

Inquiry now

|

Wedge Wire Screen |

|

Water filter hub lateral as an efficient collector, the screen lateral is available in several sizes, with various slots and end fittings.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire screen header lateral water distributors are extensively used in draining operations with the features of effective filtering and webbing performance.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Header Lateral Distributor Filters System can be widely used in all kinds of industry factory filtration processes and screening processes. It is the best filter for industry water treatment and liquid filtration.

Inquiry now

|

Wedge Wire Screen |

|

SS v wire wedge screen nozzle filter is composed of V-profile wire stainless steel which is spirally wrapped in certain equal slot. To maintain the slot size around inside and add extra strength are mounted. It has each cover for both ends of nozzle.Each wire and rod are made by spot welding. and fitting pipe is adjusted according to the thickness of set bottom plate.Nozzle is completed by welding fitting pipe to a cover of down end after setting screw according to the type of nut.

Inquiry now

|

Wedge Wire Screen |

|

SS v wire wedge screen nozzle filter is composed of V-profile wire stainless steel which is spirally wrapped in certain equal slot. To maintain the slot size around inside and add extra strength are mounted. It has each cover for both ends of nozzle.Each wire and rod are made by spot welding. and fitting pipe is adjusted according to the thickness of set bottom plate.Nozzle is completed by welding fitting pipe to a cover of down end after setting screw according to the type of nut.

Inquiry now

|

Wedge Wire Screen |

|

The header lateral has two type: threaded ending wedge wire screen lateral and flange ending wedge wire screen lateral. Threaded ending wedge wire screen laterals are composed of a solid cap on one end and a threaded pipe connection on the other end. The flange ending wedge wire screen lateral is composed of solid cap on one end and a flange. The different design makes it possible to suit different applications and machines.

Inquiry now

|

Wedge Wire Screen |

|

Slot wire header lateral,hub lateral,collector,distributor .UBO Provide even distribution or collection and avoid flow/pressure concentrations such as dead zones, wall effects or channeling.

Inquiry now

|

Wedge Wire Screen |

|

Our filter nozzles are an excellent technical and economical solution in bringing together a fully welded, strong and highly corrosion resistant structure and with a non-plugging surface.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire Mash are placed in a housing, inline with the flow to capture expensive media from traveling downstream. We can design the traps to capture media particles of any size. With the continuous open slot, the traps provide sufficient open area to let process flow move smoothly thus minimizing pressure loss through the system.

Inquiry now

|

Wedge Wire Screen |

|

Hub laterals promote even distribution while also avoiding flow/pressure concentrations. The non-plugging hub style design is ideal for accommodating disc head vessels. Made to your specification of size, open area and material, you can expect easy maintenance and exceptional long-term durability. We can builds hub laterals to your specifications for material, wire and rod size as well as open area.

Inquiry now

|

Wedge Wire Screen |

|

hub radial laterals factory for exchange resin is made of V shaped stainless steel wire. It has flow area.water distribution uniformity, the high mechanical strength, temperature,pressure,anti aging, anti corrosive has been greatly enhanced. Stainless steel wire around the space under the index finger to the size of the design.

Inquiry now

|

Wedge Wire Screen |

|

The stainless steel hub lateral can be designed with slot openings and wires running radially onthe outside for flow from outside to inside. Or they can be positioned axially on the inside of the cylinder for flow from inside to outside.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire screen hub lateral performs well in media filters, sand filters, carbon strip vessels, carbon towers, clay filters and in many water and waster water treatment application.

Inquiry now

|

Wedge Wire Screen |