|

The wedge wire basket is widely used in many industries in screening, filtering, dehydration, mud, and other operations.

Inquiry now

|

Wedge Wire Screen |

|

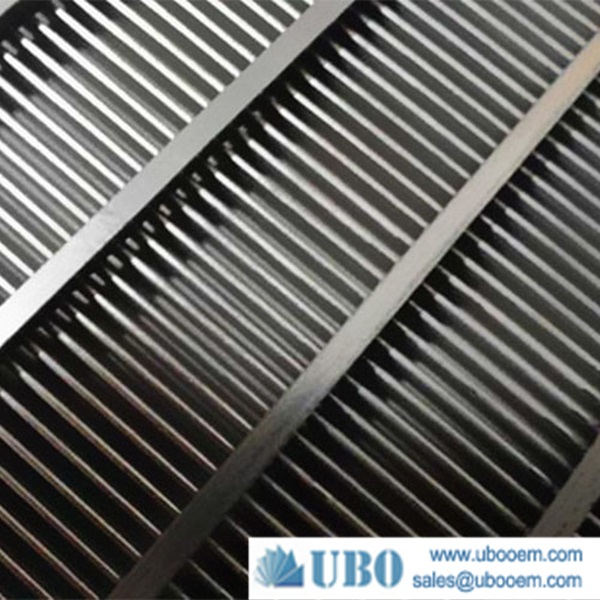

Fetures of wedge wire screen basket:,The wire shape is inverse triangle,it makes the pulp flows out amoothly,and decreases the resistance.

Inquiry now

|

Wedge Wire Screen |

|

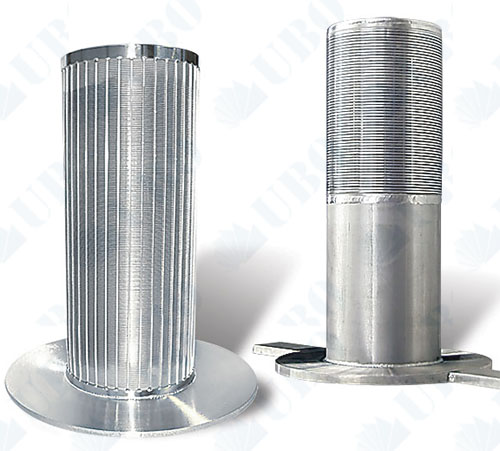

Centrifuge basket,Screen basket is centrifuge dewatering equipment of key components, screen basket is mainly used in centrifugal machine dehydration, widely used in coal, chemical industry, metallurgy industry, etc. Screen basket is one of the key components of centrifugal machine, high speed rotating parts is, not only to withstand vibration sieve basket load, but also bear coal, water serious impact, so the strength and the accuracy is higher.,The main screen by the Centrifuge basket is centrifuge dewatering equipment of key components, screen basket is mainly used in centrifugal machine dehydration, widely used in coal, chemical industry, metallurgy industry, etc. Screen basket is one of the key components of centrifugal machine, high speed rotating parts is, not only to withstand vibration sieve basket load, but also bear coal, water serious impact, so the strength and the accuracy is higher.

Inquiry now

|

Wedge Wire Screen |

|

pressure screen filters, typically made from perforated plate with hole diameters of less than 0.008 in. / 0.20 mm, can be used to recover fibers in water streams, to remove fibers in water used on the paper machine or in dilution water for the headbox. Using a pressure screen filter eliminates the risk of stringing and of plugging the water nozzles.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire screen drum basket is composed of rod strips and V shaped wires through manufacturing on specialized welding machine.,The rib strips and V shaped wires will be welded by resistance welding, has enough welding strength, equally slot gap, high corrosion resistance, large filter area, good permeability, simple structure,

Inquiry now

|

Wedge Wire Screen |

|

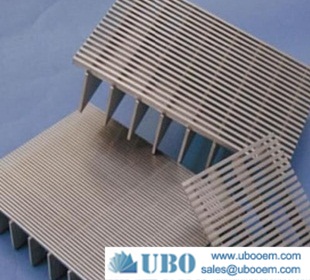

wedge wire screen support grids are widely used in steel structure platforms, stair treads, sidewalks, drainages and well covers etc. We can design and manufacture standard steel grating and in customized shapes per client's requirements.

Inquiry now

|

Wedge Wire Screen |

|

gravity fed boxes are typically applied to make The gravity fed boxes are typically applied to make coarse separations ahead of the degerminators and in multistage germ washing. The system uses a Wedge Wire dewatering screen to retain the solids while allowing effluent to run through the system. The slurry is gravity fed to the head box and flows to the screen. The solids retained from the screen gather for disposal or reuse.

Inquiry now

|

Wedge Wire Screen |

|

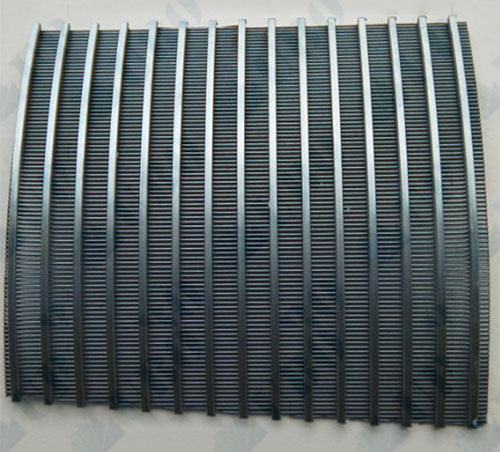

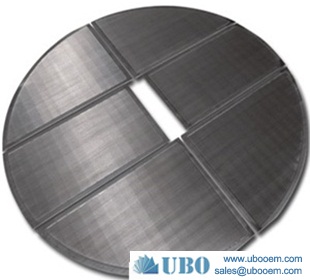

Stainless steel flat wedge screen panel is made of V shaped rod or Convex shape wire with an unique welding process, offering great strength precision ,long service life.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Screen Panels are used in the filtration industry,dewatering,desliming,jigging machines,sieve bend,wedge wire grating and vibrating screens.

Inquiry now

|

Wedge Wire Screen |

|

stainless steel static wedge wire screen panels for ventilation is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine, then be made to screen panel through cutting and edge welding. Each profile wire and support rod is welded by resistance welding.,

Inquiry now

|

Wedge Wire Screen |

|

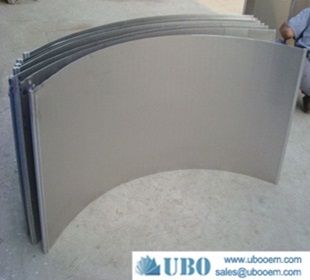

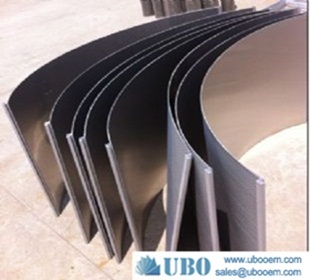

Vibrating Screen Panels consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

Inquiry now

|

Wedge Wire Screen |

|

UBO manufactures a variety of Sidewall Screens used in the sugar industry – including sidewall tower and cossette mixer screens. These high quality, long lasting screens are looped wedge wire constructed to provide the ultimate value to the market.,

Inquiry now

|

Wedge Wire Screen |

|

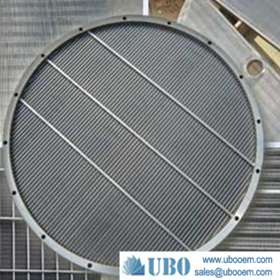

UBO high quality custom built flat panel wedge wire screens, manufactured either framed or unframed with a variety of support rods, offers a high strength, long lasting, economical solution to the market. They come in commonly shaped wedge wire profiles and offer good screening efficiency across a wide range of applications. Flat wedge wire screens are excellent for use to de-water, de-slim, drain and rinse, wet classify, dry classify, filter, dry and cool. They are recommended for use in any application that requires efficient liquid-solid separation.

Inquiry now

|

Wedge Wire Screen |

|

radiused screen cylinder is used in a wide variety of processes across several industry sectors. We use state-of-the-art manufacturing techniques that place our products at the cutting edge of wedge wire screen construction. Flat panels can be designed and manufactured according to customer specifications and come in a wide range of grades - from fine gap screens for small particle sizes to heavy duty screens for heavy load applications.,

Inquiry now

|

Wedge Wire Screen |

|

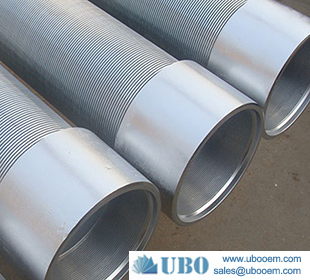

slotted screen cylinder are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Inquiry now

|

Wedge Wire Screen |

|

SS Wedge Wire v wire wrapped water well screen tube (V-shaped wire). The Industrial wedge wire wrapped screen have a robust structure and large open area, as well as accurate slot dimension. At the same time, wedge wire screens pipe have many advantages such as heat-resisting, anti-corrosive, good machine capability,long service life, safety and reliability and so on. It can be used in many kinds of medium filtering.,

Inquiry now

|

Wedge Wire Screen |

|

Drilled screen Cylinder are placed in a housing, inline with the flow to capture expensive media from traveling downstream. We can design the Drilled screen Cylinder to capture media particles of any size. With the continuous open slot, the traps provide sufficient open area to let process flow move smoothly thus minimizing pressure loss through the system.,Your resin trap can be designed to suit either new or existing strainer bodies.

Inquiry now

|

Wedge Wire Screen |

|

TheFish Protection Screens System design utilizes low velocity flow(typically < 1/2 fps) through the wedge wire screen surface which minimizes impingement and danger to aquatic life.,Profile wire fish screens prevent entrainment, injury, or death of the targeted aquatic species by physically precluding fish from entering a water intake.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire screen support grids offer a relatively flat and smooth surface to reduce degradation of the media in down-flow processes.

Inquiry now

|

Wedge Wire Screen |

|

If you have any question on Backwashing Filter Bottom Distributor 304 Screen Nozzle. We will give the professional answers to your questions.

Inquiry now

|

Wedge Wire Screen |