| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request |

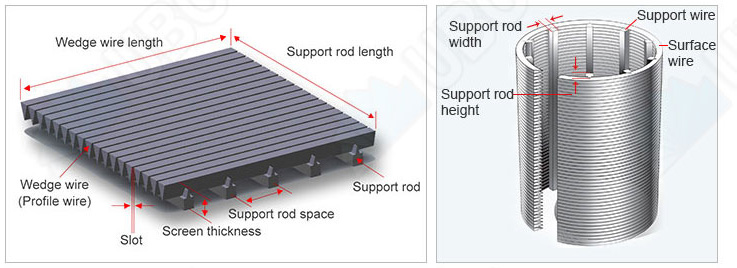

| Properties: | Wedge Wire Screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

wedge wire screen for food beverage processing can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

1. Screens with high open area are more suitable for the construction of high-quality water wells, oil wells and gas wells.

2. Low cost operation Screens with high open area shall favor groundwater infiltration. Abundant water shall reduce the water levels down, thus to save energy consumption.

3. Reduce the abrasion of the pump

Under the same condition, high open area can make the speed of groundwaters entering into the screen much slower than any other filtration apparatus, which will avoid sands entering into.

Application in deep well pump to dive the water pump, in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment; the petroleum industry, the petroleum product terminal filters; and the chemical acid, the alkali liquid filters, the ethyl alcohol and the organic solution recycling filters.

Profile Screen Laterals is made of V shaped stainless steel wire. It has flow area.water distribution uniformity, the high mechanical strength, temperature,pressure,anti aging, anti corrosive has been greatly enhanced. Stainless steel wire around the space under the index finger to the size of the design.

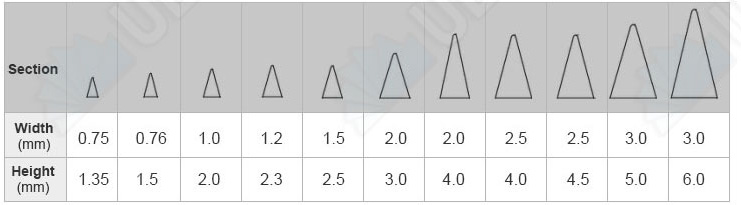

specification (wedge wire ):

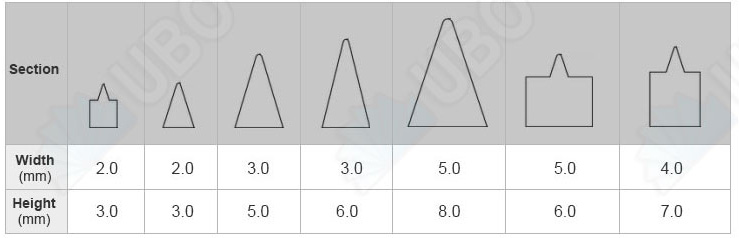

specification (support rod):

Note: this is the normal wire, others could customized

| Outside Diameter | Profile wire | Rod wire | Rod quantity | Slot size | Length | ||

| DN | Inch | mm | mm | mm | mm | mm | |

| 20 | 3/4 | 26.9 | 1.5*2 | 2*3 | 12 | 0.1~0.25 | 45~3000 |

| 25 | 1 | 33.7 | 1.5*2 | 2*3 | 14 | 0.1~0.25 | 45~3000 |

| 32 | 1~1/4 | 42.4 | 1.5*2 | 2*3 | 16 | 0.1~0.25 | 45~3000 |

| 40 | 1~1/2 | 48.3 | 1.5*2 | 2*3 | 16 | 0.1~0.25 | 45~3000 |

| 50 | 2 | 60.3 | 1.5*2 | 2*3 | 18 | 0.1~0.5 | 45~3000 |

| 65 | 2~2/2 | 76.1 | 1.5*2 | 2*3 | 20 | 0.1~0.5 | 45~3000 |

| 80 | 3 | 88.9 | 1.8*2.5 | 2*3 | 24 | 0.1~0.5 | 45~3000 |

| 100 | 4 | 114.3 | 1.8*2.5 | 2*3 | 30 | 0.5~2 | 1000~6000 |

| 125 | 5 | 139.7 | 2.3*2.7 | 2*3 | 36 | 0.5~2 | 1000~6000 |

| 150 | 6 | 168.3 | 2.3*2.7 | 3*5 | 44 | 0.5~2 | 1000~6000 |

| 200 | 8 | 219.1 | 3.3*4.5 | 3*4.7 | 56 | 0.5~2 | 1000~6000 |

| 250 | 10 | 273 | 3.3*4.5 | 4*6 | 66 | 0.5~2 | 1000~6000 |

| 300 | 12 | 323.9 | 3.3*4.7 | 4*6 | 72 | 0.5~2 | 1000~6000 |

| 350 | 14 | 355.6 | 3.7*5 | 4*6 | 80 | 0.5~2 | 1000~6000 |

| 400 | 16 | 406.4 | 1.5*2 | 2*3 | 94 | 0.1~2 | 1000~6000 |

| 450 | 18 | 457 | 2*3 | 4*5 | 112 | 0.1~2 | 500~400 |

| 500 | 20 | 508 | 2*3 | 4*5 | 124 | 0.1~2 | 500~400 |

| 550 | 22 | 559 | 2*3 | 4*5 | 140 | 0.1~2 | 500~400 |

| 600 | 24 | 610 | 2*3 | 4*5 | 156 | 0.1~2 | 500~400 |

| Siot:0.1mm~2mm Tolerance:0.05 | |||||||