| Category: | Header-Lateral |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

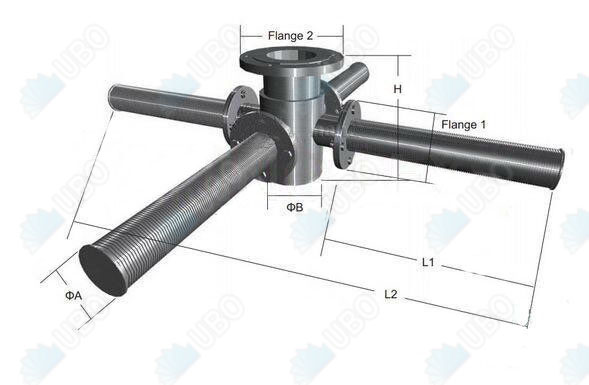

| Properties: | Hub Laterals |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

Wedge wire lateral assemblies is widely used in the under draining applications with the features of effective filtering and screening performance. Wedge wire lateral assemblies are a typical screen type used in the under draining.

Wedge wire lateral assemblies, also called header lateral assemblies, are assemblies of horizontal herring bone style wedge wire screenlaterals and vertical secured round hub. The screen lateral has inherent even pattern, which is made of stainless steel, hastelloy alloy steel and other alloy steels. The screen lateral has various slot size, wire size and diameters to suit common or customized applications.

wedge wire type hub and header lateral consist of a series of screen laterals connected to either a central-header pipe or a hub, they are important components of ion exchange units, media filters, sand filters, carbon strip vessels, carbon towers, clay filters and in many water and waster water treatment applications.

1. Screens with high open area are more suitable for the construction of high-quality water wells, oil wells and gas wells.

2. Low cost operation.

3. Reduce the abrasion of the pump.

With the advantage of the wrap wire screens pipe,large flow area, uniform water distribution, high mechanical strength,temperature resistance, pressure resistance, aging resistance,corrosion resistance have been greatly improved. Even if the branch pipe bending occurs, the resin still can’t flow out.Stainless steel wire slot size can be designed according to the resin size.

| nominal diameter | Branch diameter | Branch Qty | The specification of the nominal flange |

| 1500 | 45-76 | 4-12 | DN100 |

| 2000 | 45-76 | 4-12 | DN125 |

| 2500 | 57-89 | 4-12 | DN150 |

| 3000 | 57-108 | 4-12 | DN200 |

| 3200 | 57-108 | 4-12 | DN200 |