| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel |

| Properties: | Wedge Wire Screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration |

conical centrifuge screens baskets are more complex than the other types of screens requiring extra strength to withstand the stresses of centrifuge dryers. These baskets are typically used in mineral processing for coal, potash, salt, sand, pulp,paper and a variety of chemicals. They are also used for refuse removal from oil and gas drillers.

widely used in mineral processing,coal processing,food processing,water treatment,petrochemical industry,architecture industry, as well as many other applications involving liquid & solids separation.

Maximum effective flow area and maximum operating efficiency are maintained throughout service life.

Maintenance costs are reduced drastically due to reduced clogging and stapling of fibrous material.

Long-lived straining element provides reduced operating costs over entire service life.

Rigid element prevents flexing which can cause premature element failure.

Efficient, effective debris collection at media/screen interface.

We can also make manufacture according to your detail specifications and we assure that we will give you the best services.

If you are interested in our products please feel free to contact us and your inquiry will meet with our careful attention.

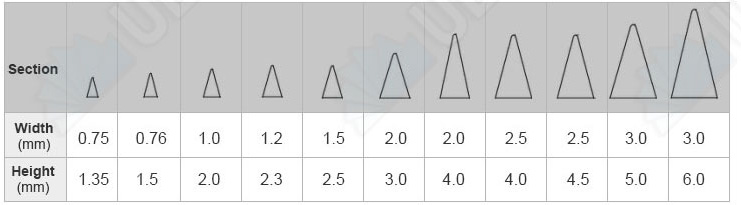

specification (wedge wire ):

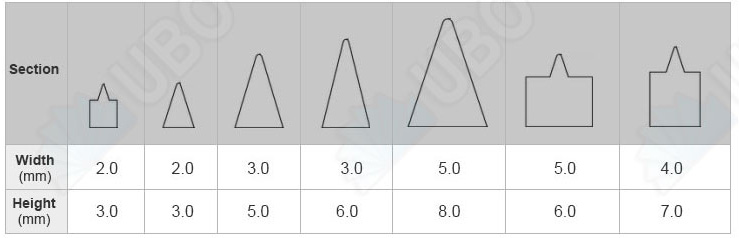

specification (support rod):

Note: this is the normal wire, others could customized

| Outside Diameter | Profile wire | Rod wire | Rod quantity | Slot size | Length | ||

| DN | Inch | mm | mm | mm | mm | mm | |

| 20 | 3/4 | 26.9 | 1.5*2 | 2*3 | 12 | 0.1~0.25 | 45~3000 |

| 25 | 1 | 33.7 | 1.5*2 | 2*3 | 14 | 0.1~0.25 | 45~3000 |

| 32 | 1~1/4 | 42.4 | 1.5*2 | 2*3 | 16 | 0.1~0.25 | 45~3000 |

| 40 | 1~1/2 | 48.3 | 1.5*2 | 2*3 | 16 | 0.1~0.25 | 45~3000 |

| 50 | 2 | 60.3 | 1.5*2 | 2*3 | 18 | 0.1~0.5 | 45~3000 |

| 65 | 2~2/2 | 76.1 | 1.5*2 | 2*3 | 20 | 0.1~0.5 | 45~3000 |

| 80 | 3 | 88.9 | 1.8*2.5 | 2*3 | 24 | 0.1~0.5 | 45~3000 |

| 100 | 4 | 114.3 | 1.8*2.5 | 2*3 | 30 | 0.5~2 | 1000~6000 |

| 125 | 5 | 139.7 | 2.3*2.7 | 2*3 | 36 | 0.5~2 | 1000~6000 |

| 150 | 6 | 168.3 | 2.3*2.7 | 3*5 | 44 | 0.5~2 | 1000~6000 |

| 200 | 8 | 219.1 | 3.3*4.5 | 3*4.7 | 56 | 0.5~2 | 1000~6000 |

| 250 | 10 | 273 | 3.3*4.5 | 4*6 | 66 | 0.5~2 | 1000~6000 |

| 300 | 12 | 323.9 | 3.3*4.7 | 4*6 | 72 | 0.5~2 | 1000~6000 |

| 350 | 14 | 355.6 | 3.7*5 | 4*6 | 80 | 0.5~2 | 1000~6000 |

| 400 | 16 | 406.4 | 1.5*2 | 2*3 | 94 | 0.1~2 | 1000~6000 |

| 450 | 18 | 457 | 2*3 | 4*5 | 112 | 0.1~2 | 500~400 |

| 500 | 20 | 508 | 2*3 | 4*5 | 124 | 0.1~2 | 500~400 |

| 550 | 22 | 559 | 2*3 | 4*5 | 140 | 0.1~2 | 500~400 |

| 600 | 24 | 610 | 2*3 | 4*5 | 156 | 0.1~2 | 500~400 |

| Siot:0.1mm~2mm Tolerance:0.05 | |||||||