| Category: | Water Strainer & Nozzle |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request |

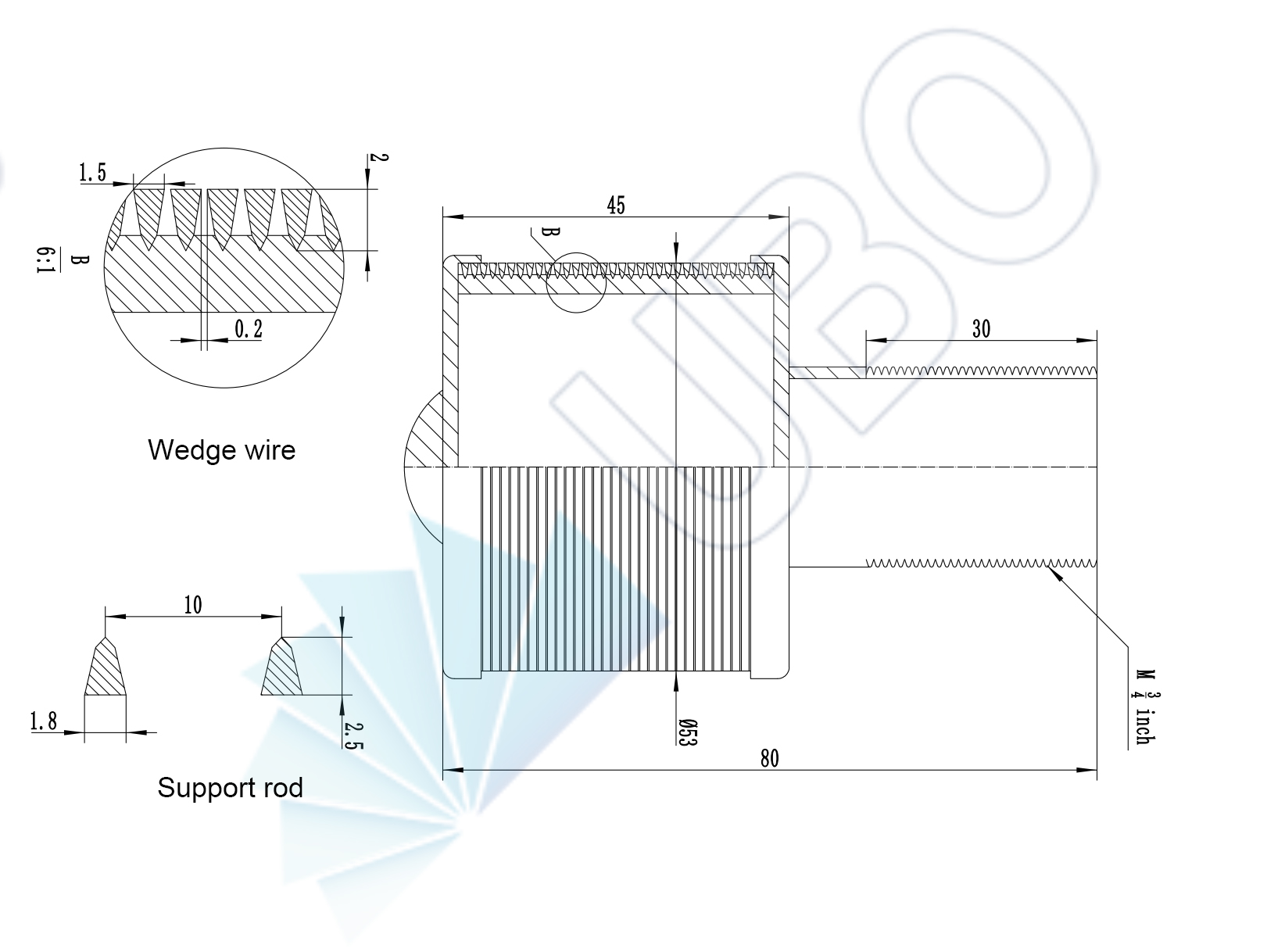

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

Wedge wire water strainer nozzle are used in liquid/solid or gas/solid separation (sand, catalyst, resins, zeolite etc). The design of each nozzle and the exact quantity will be proposed in order to obtain a perfect distribution or collection of flow.

Our filter nozzles are an excellent technical and economical solution in bringing together a fully welded, strong and highly corrosion resistant structure and with a non-plugging surface.

-- Catalytic processes

-- Ion exchange processes

-- Sand filters

-- Activated carbon processes

-- Filter nozzles design

1) Strength: As fourth and fifth layers do support, with high mechanical strength and compressive strength.

2) Easy to clean: As a result of surface of the filter material, having means for cleaning characteristics, especially suitable for backwashing.

3) Easy processing: suitable for cutting, bending, stamping, drawing, welding and other processes.

4) High temperature: 480 °Ccan withstand high temperatures.

5) Corrosion resistance: As a result of SUS316L, 304 materials, the corrosion resistance.

6) Filtration: Filtration range of 1μm-200μm, has a reliable filter performance.

7) Stability: Because there are two layers to do to protect the screen, plus solid melting diffusion sintering process which make filters is not easily to deform.

-- Used in food and beverage industry (milk powder, tea, coffee and etc).

-- Used in chemical and pharmaceutical industry (pharmaceutical products,plastic Recycling and Precision sieving of powders and etc.)

-- Used in petrochemical industry.

-- Used in water treatment system.

-- Used in aerospace industry

| D | L | L1 | Slot Size | d | Flow Area mm2 |

| 45 | 98 | 34 | 0.2-0.25 | M20 | 380-493 |

| 45 | 100 | 44 | 0.2-0.25 | M24 | 551-690 |

| 53 | 100 | 34 | 0.2-0.25 | M24 | 453-597 |

| 53 | 100 | 44 | 0.2-0.25 | M27 | 680-710 |

| 53 | 105 | 50 | 0.2-0.25 | M32 | 800-920 |

| 57 | 115 | 34 | 0.2-0.25 | M30 | 560-670 |

| 57 | 120 | 55 | 0.2-0.25 | M32 | 780-905 |

| 60 | 120 | 55 | 0.2-0.25 | G1" | 905-1100 |

| 82 | 130 | 50 | 0.2-0.25 | M33 | 1170-1280 |

| 108 | 200 | 100 | 0.2-0.25 | G2" | 3050-4600 |