| Category: | Sieve Plate Screen |

| Material: | Stainless Steel |

| Properties: | Wedeg Wire Screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

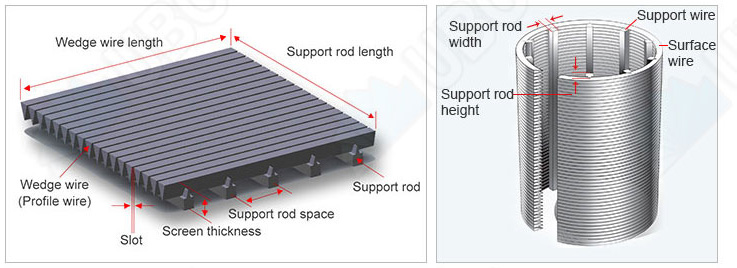

Wedge wire Mash can be manufactured with a variety of rectangular or round support rods. The wire width and relief angle is determined by weight per square foot and efficiency requirements. This screen decking magnifies vibration with drum-tight tension and withstands the violent vibrating action. These industrial profile screens are also used in fluid bed dryers, coolers and much more.

Our Wedge wire Mash are all custom made and can be designed and built to fit any screening equipment in any specified width and length. Need a stainless steel Wedge Wire screens on an extra-large scale? No problem. Plus, size, shape and spacing of profile wire are engineered to meet your special job requirements. Individual wire on the working surface of each wedge wire flat panel screen can be manufactured at a tilt to better serve your need.

Accurate slot gap, high efficiency performance, stable structure, anti-high temperature, anti-corrosive, good mechanical properties, long-lasting and durable, safe and reliable, various field can be applied.

Wedge Wire screens are used for wide range of applications such as sizing, classification and de-watering in mining and other industries. These are used for coal & iron ore beneficiations when fitted on the vibratory machine.

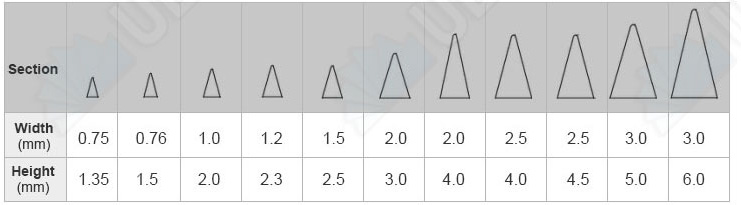

specification (wedge wire ):

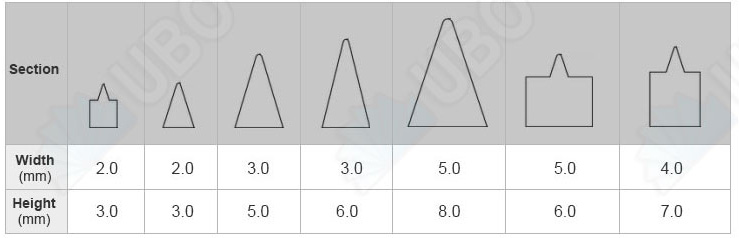

specification (support rod):

Note: this is the normal wire, others could customized

| Outside Diameter | Profile wire | Rod wire | Rod quantity | Slot size | Length | ||

| DN | Inch | mm | mm | mm | mm | mm | |

| 20 | 3/4 | 26.9 | 1.5*2 | 2*3 | 12 | 0.1~0.25 | 45~3000 |

| 25 | 1 | 33.7 | 1.5*2 | 2*3 | 14 | 0.1~0.25 | 45~3000 |

| 32 | 1~1/4 | 42.4 | 1.5*2 | 2*3 | 16 | 0.1~0.25 | 45~3000 |

| 40 | 1~1/2 | 48.3 | 1.5*2 | 2*3 | 16 | 0.1~0.25 | 45~3000 |

| 50 | 2 | 60.3 | 1.5*2 | 2*3 | 18 | 0.1~0.5 | 45~3000 |

| 65 | 2~2/2 | 76.1 | 1.5*2 | 2*3 | 20 | 0.1~0.5 | 45~3000 |

| 80 | 3 | 88.9 | 1.8*2.5 | 2*3 | 24 | 0.1~0.5 | 45~3000 |

| 100 | 4 | 114.3 | 1.8*2.5 | 2*3 | 30 | 0.5~2 | 1000~6000 |

| 125 | 5 | 139.7 | 2.3*2.7 | 2*3 | 36 | 0.5~2 | 1000~6000 |

| 150 | 6 | 168.3 | 2.3*2.7 | 3*5 | 44 | 0.5~2 | 1000~6000 |

| 200 | 8 | 219.1 | 3.3*4.5 | 3*4.7 | 56 | 0.5~2 | 1000~6000 |

| 250 | 10 | 273 | 3.3*4.5 | 4*6 | 66 | 0.5~2 | 1000~6000 |

| 300 | 12 | 323.9 | 3.3*4.7 | 4*6 | 72 | 0.5~2 | 1000~6000 |

| 350 | 14 | 355.6 | 3.7*5 | 4*6 | 80 | 0.5~2 | 1000~6000 |

| 400 | 16 | 406.4 | 1.5*2 | 2*3 | 94 | 0.1~2 | 1000~6000 |

| 450 | 18 | 457 | 2*3 | 4*5 | 112 | 0.1~2 | 500~400 |

| 500 | 20 | 508 | 2*3 | 4*5 | 124 | 0.1~2 | 500~400 |

| 550 | 22 | 559 | 2*3 | 4*5 | 140 | 0.1~2 | 500~400 |

| 600 | 24 | 610 | 2*3 | 4*5 | 156 | 0.1~2 | 500~400 |

| Siot:0.1mm~2mm Tolerance:0.05 | |||||||