| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen pipe |

| Application: | water-treatment,beer brewing,water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant,refining & petrochemical |

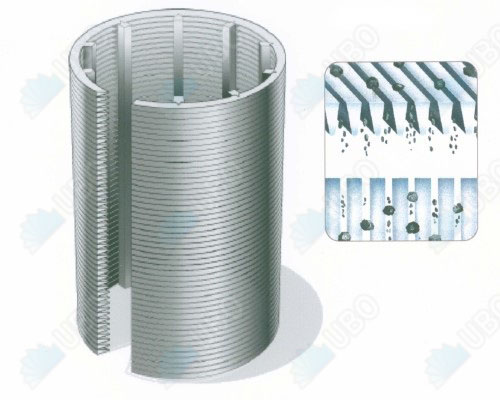

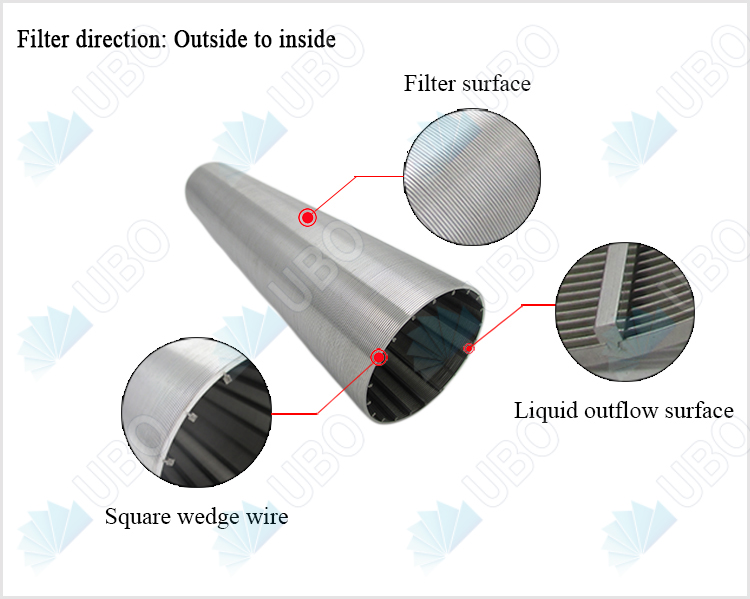

Wedge Wire wedge wire screen tube filter strainer is composed of ribs and V—winding wire, manufactured with advanced special welding equipment.Ribs and V—winding wire are connected with resistance weld by special equipment and has the advantages, such as, high welding strength, homogeneous gap, corrosion resistance, large effective filtration area, good permeability,simple structure, and slot size is 20 micron or larger for users to choose freely.

1) Screens with high open area are more suitable for the construction of high-quality water wells, oil wells and gas wells.

2) Low cost operation Screens with high open area shall favor groundwater infiltration. Abundant water shall reduce the water levels down, thus to save energy consumption.

3) Reduce the abrasion of the pump

Under the same condition, high open area can make the speed of groundwaters entering into the screen much slower than any other filtration apparatus, which will avoid sands entering into.

deep well , water well , geothermal well , tube well , oil and gas exploration well , irrigation well , resident and industrial using well.

| Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 |

|

Note: |

other specifications available as per request |

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packing: in wood case.