| Category: | Water Strainer & Nozzle |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request |

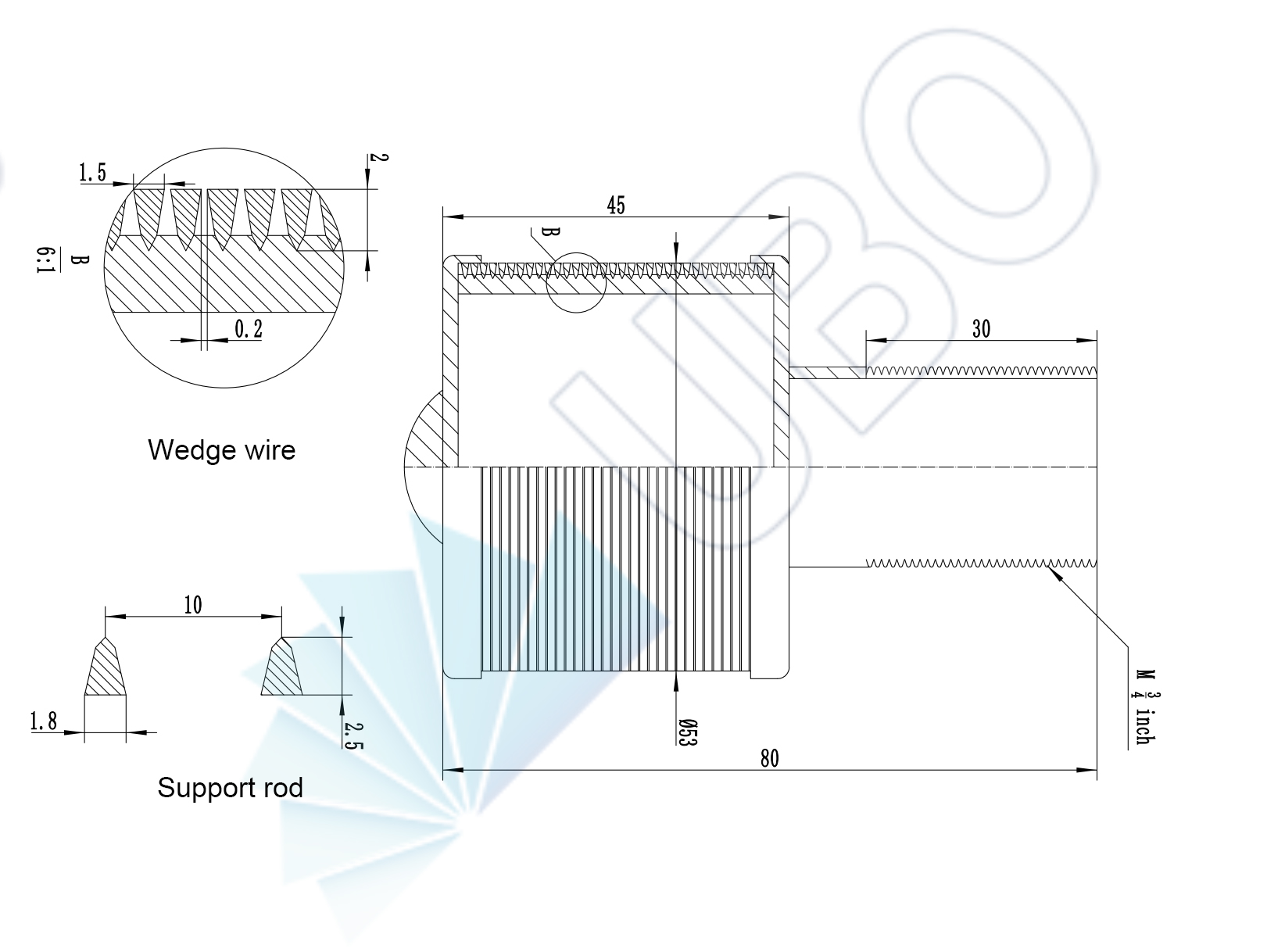

| Properties: | wedge wire screen |

| Application: | water-treatment, water well drilling,oil well drilling,mineral processing, coal-cleaning plant |

The wedge wire screen nozzles. Nozzles are closed on one side and have a threaded fitting on the other. The screen nozzle with thread coupling can be fixed on the filtering equipment for the filteration of water petrol resin and other medium.One rubber shim , one steel shim and two thin nuts of the same material for a nozzle.

The wedge wire screen filter nozzle can be fixed on the filtering equipment for the filteration of water petrol resin and other medium. Also it can be used in the water treatment, water softhening, conversion of sea water into fresh water, the filter of food chemistry.

1) Type 316L stainless steel construction.

2) Continuous slot design provide large circulation area

3) Standard nozzle are 2in/51mm diameter and can be attached to the plate either with threaded end fittings or "L" blots.

4) Standard slot opening is typically range between 0.006”(0.15mm), and 0.020in./0.50mm wide suitable for 40 to 50 mesh size media, Other slot sizes are also available.

5) Wedge wire screen is highly resistant to plugging.

6) Choice of either 3/4” NPT or 1” NPT fittings are available from stock. Other styles, such as tee-bolt mountings, and drop tubes are readily available.

7) Unaffected by temperature, corrosion resistant, aging resistant, long life span, easy change, saftey and enviormental friendly.

Manfre introduce advanced korea technology , the construction method used is the latest, ultra clean TiG and plasma welding system. This method of construction guarantees cartridge integrity, eliminating the risk of bypass and the presence of extractables derived from any bonding agents.

|

No. |

Type |

Ton |

Slot Opening |

Size |

0.2-0.25mm slot opening Area of through-flow mm2 (reference) |

|||

|

D |

L1 |

L |

M |

|||||

|

1 |

TYS45-1-C |

0.5 |

0.2-0.5 |

45 |

45 |

95 |

24 |

500 |

|

2 |

TYS53-2-B |

1 |

0.2-0.5 |

53 |

45 |

100 |

24 |

570 |

|

3 |

TYS53-2-C |

1.5 |

0.2-0.5 |

53 |

50 |

110 |

32 |

700 |

|

4 |

TYS57-3-B |

2 |

0.2-0.5 |

57 |

45 |

110 |

32 |

600 |

|

5 |

TYS70-4-B |

3 |

0.2-0.5 |

70 |

55 |

120 |

32 |

1000 |