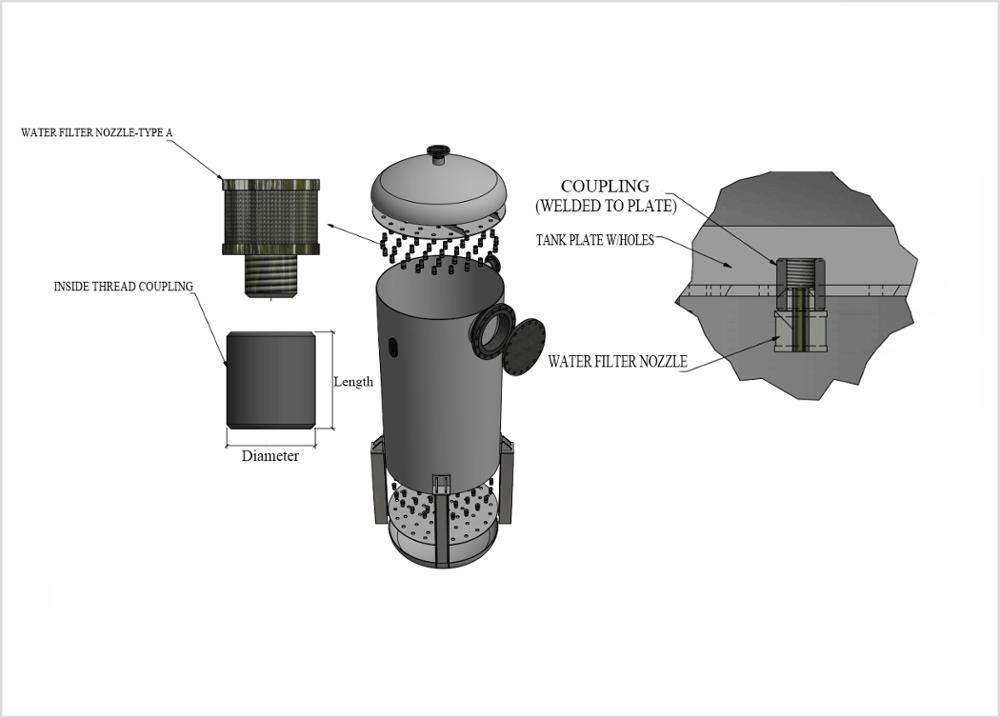

| Category: | Water Strainer & Nozzle |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request |

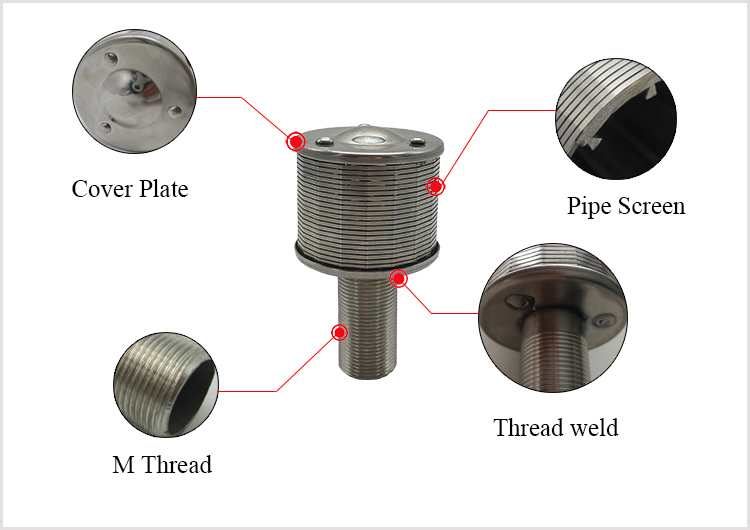

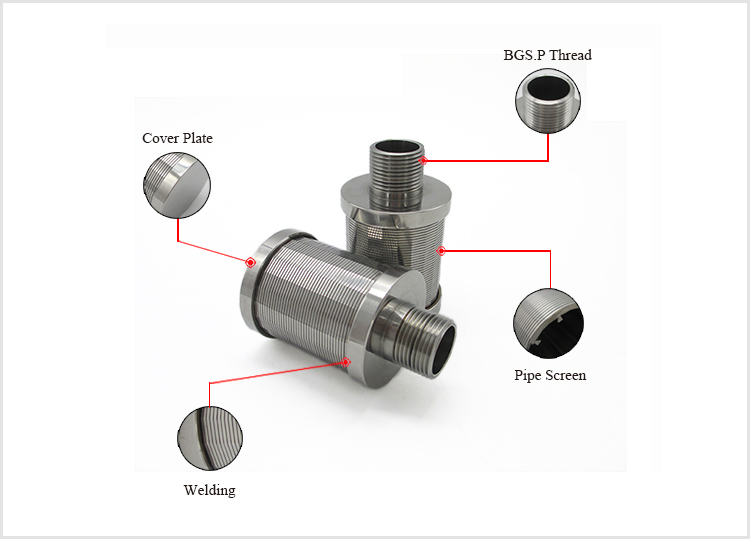

| Properties: | filter nozzle |

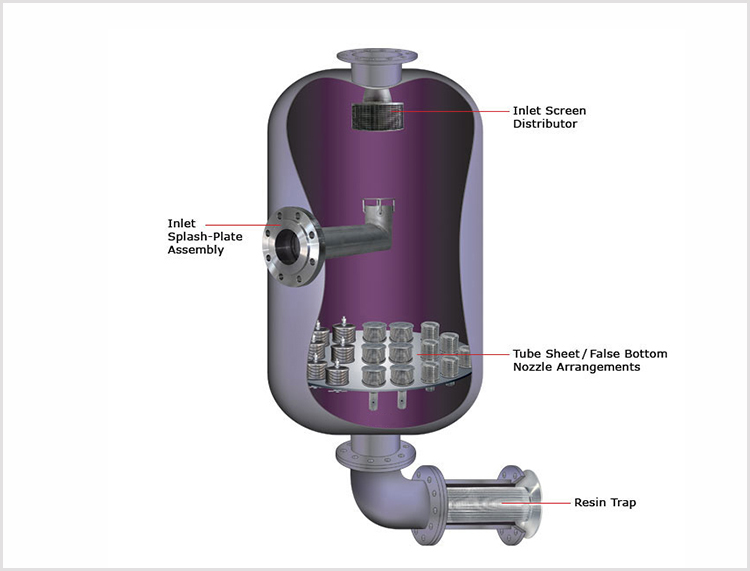

| Application: | solid-liquid separation and recovery. Especially for beer waste water, papermaking wastewater, slaughtering waste water, juice processing wastewater |

Stainless Steel v wire type wedge wire screen filter nozzle have the features of great strength, precision, long service life and a wide range of applications in the field of process and engineering such as waste water treatment, sugar juice filtration, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, water, fuels, paints, food products, liquid cooling agents, and chemicals etc.

Wedge Wire Screen has a continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone (the aquifer)

A uniform and efficient well development due to the continuous slot opening.

A "V" shaped profile wire which avoids clogging and ensures an uninterrupted flow.

- De-watering;

- Separating;

- Filtering;

- Straining;

- Sizing;

- Drying;

- Media retention

- Water intake;

|

|

|||||||

|

Type |

Slot (mm) |

Dimension |

Flow Rating (M3/H) |

||||

|

D(mm) |

H(MM) |

L(MM) |

Thread |

Fittings |

|||

|

UBO-0.5 |

0.25 |

45 |

45 |

90/request |

M,NPT, G, PT(BSPT),Z,BSP, request |

SS Gasket, Rubber gasket, Nut, request |

0.5 |

|

UBO-1.0 |

0.25 |

53 |

45 |

90/request |

1.0 |

||

|

UBO-1.5 |

0.25 |

57 |

45 |

90/request |

1.5 |

||

|

UBO-2.0 |

0.25 |

57 |

55 |

100/request |

2.0 |

||

|

UBO-2.5 |

0.25 |

70 |

55 |

100/request |

2.5 |

||

|

UBO-3.0 |

0.25 |

70 |

70 |

120/request |

3.0 |

||

|

Note |

* All the above size are the normal size. Customized size is possible. * UBO could help to design according to the application and requirement. * The nozzles customized range as below: 1. Slot range: 0.05-2mm 2. Dimension: Diameter, Screen Height, Length could produce according to actual requirement and application 3. Thread according to requirement |

||||||