| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen cylinders |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

Rotary fine wire screen Rotary fine wire screens are used for mechanical separation of solid particles from liquids. They are made from fine wire screens with carrying and strengthening structure. They are characterized by capability of working in continuous mode, high efficiency combined with low energy consumption and self-cleaning. Mesh From 0,02mm Material Stainless and acid-resistant steel (see wedge wire screens – materials.) Dimensions Depending on purpose and demanded output (Standard: Ø – 300, 405, 600, 640, 900, 916, 1230mm; length: 500-3500mm)

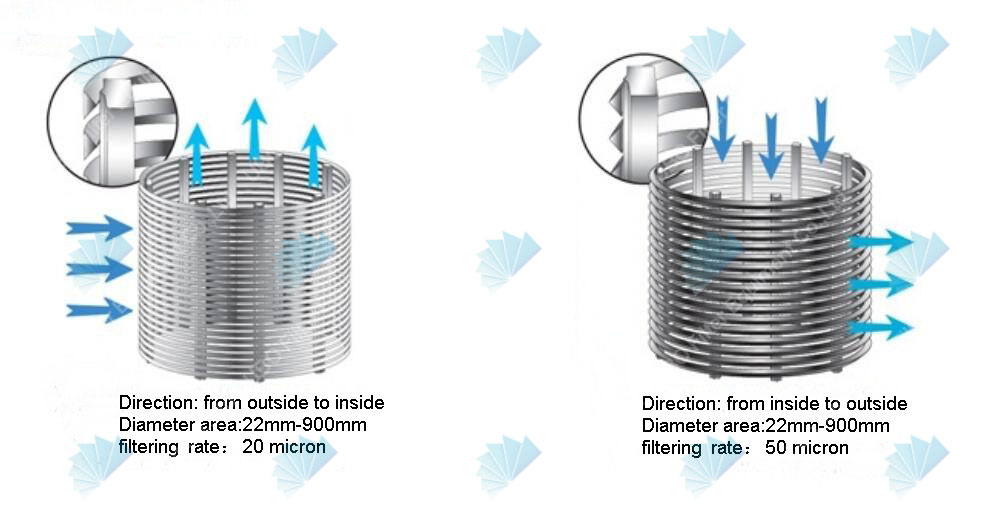

Wedge wire products are used for solid / liquid and solid / gas separation, sizing, dewatering and media retention in Oil & Gas wells, Water Wells, monitoring & soil sanitation, the (petro) chemical industry, food and process industry and architecture.

1. Many wing pieces, no winding, highly efficient rotary drum type rotor.

2. Pulp consistency can reach 2.5~4%, reduce water consumption and fiber loss of production process.

3. Heavy impurity discharge tube, ensure the security of the sieve drum operation.

4. Advanced structure, strong and durable, easy dismounting, low energy consumption, less wastage fiber.

5. Equipped with automatic oiling and mechanical seal water monitoring device, high degree of automation.

6. Compact structure, small power, high output.

7. 1 year warranty and best after-sale service

|

size |

inner diameter |

outer diameter |

|||

|

in

|

mm

|

in

|

mm

|

in

|

mm

|

|

2

|

51

|

2

|

51

|

25/8 |

67 |

|

3

|

76

|

3

|

76

|

35/8 |

92

|

|

4

|

102

|

4

|

102

|

45/8 |

117

|

|

5

|

127

|

5

|

127

|

55/8 |

143

|

|

6

|

152

|

6

|

152

|

65/8 |

168

|

|

8

|

203

|

8

|

203

|

85/8 |

219

|

|

10

|

254

|

10

|

254

|

103/4 |

273

|

|

12

|

305

|

10

|

305

|

123/4 |

324

|