| Category: | Header-Lateral |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | hader-lateral |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

Header-Lateral System For the treatment of process water such as in ‘Ion Exchange’ and in the process of removing organic matter, Completion Products offers products such as the Header-Laterals Systems to uniformly collect and distribute process flow. Sizing of both the main header pipe and the screen laterals are based on recommended through-pipe and slot opening velocities to ensure higher efficiency and lower pressure drop. Sizing of the slot size is also critical to ensure that there is no resin/media leakage. The screen laterals (screen-based or screen + drilled pipe-base) are removable and can be designed with either a flange or threaded nipple connection.

Each of our Header-Lateral Systems are carefully designed from the specified design conditions including the volumetric flow rate, allowable pressure drop through the screen, resin/media to be retained and minimum open area to list a few. Therefore it is very important to work closely with Completion Products during the design and engineering stage to ensure that all screen characteristics are accommodated.

wedge wire type hub and header lateral consist of a series of screen laterals connected to either a central-header pipe or a hub, they are important components of ion exchange units, media filters, sand filters, carbon strip vessels, carbon towers, clay filters and in many water and waster water treatment applications.

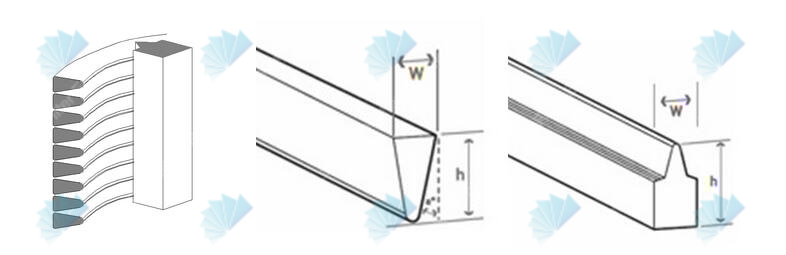

1) The V-shape section plane of Wedge wire screen pipe (Wedge Wire Screens) creates the continuous slot, which can avoid blockage and make sure of the unimpeded water.

2) The consecutive slot of Wedge wire screen pipe (Wedge Wire Screens) have wider open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can control sand better, which can increase the water yield and prolong service time of the well.

3) Wire and support rods are all-welded, which makes the Wedge wire screen pipe (Wedge Wire Screens) more robust and longer life.

4) The longitudinal support rods and the continuous slot make the Wedge wire screen pipe (Wedge Wire Screens) have more excellent pressure-resistant performance.

5) Specifications and end connections of Wedge wire screen pipe (Wedge Wire Screens) can be fabricated according to customers’ requirements.

| Specification (wedge wire): | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Package: in wood case

Delivery Time: 5-25 days