| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request |

| Properties: | Wedge Wire pipe |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant,refining & petrochemical |

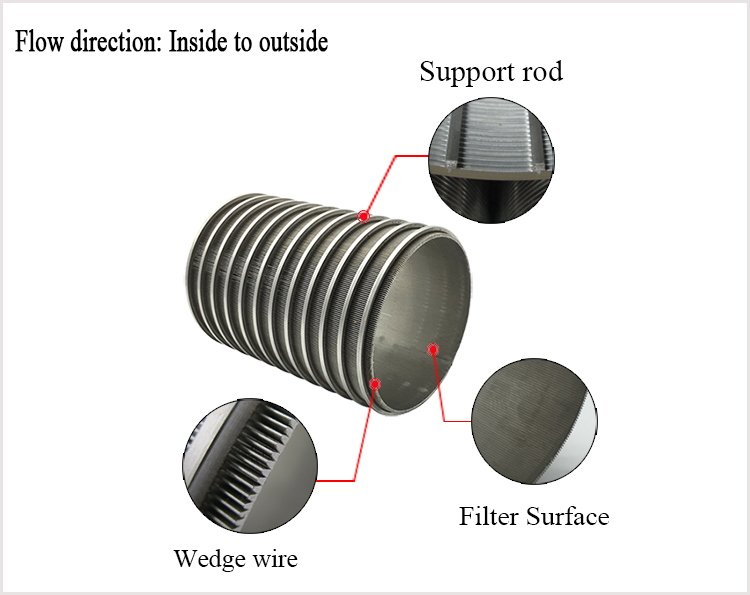

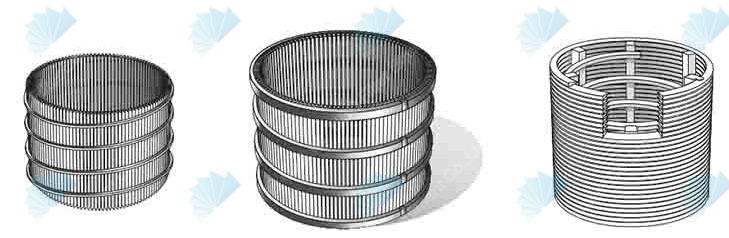

Looped or welded wedge wrapped wire screens cylinders are composed of a variety of wedge wire configurations and constructed in a spiral shaped form where the support profile is wrapped spirally by the surface. UBO uses stainless steel grade of 304, 316 and 316L sourced out from well-known stainless steel manufacturing companies.

-- Bigger filter area preventing buildups of impurities;

-- Easy maintenance / back flushing;

-- Low operational cost;

-- Minimum gap between profiles is about 20 micron (0.020mm);

-- Stop impurities/ particles with its v-shaped construction.

Wedge wires can be employed in almost all industrial processes which require very fine and uniformly accurate aperture, combining rapid discharge of material and high mechanical strength. Some of the specialized applications of these screens are given below -

Wedge wire screen used in industries for water, oil filtration equipments like

Filteration Equipments

Filtration Systems

Filters

Wedge Wire Screen

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

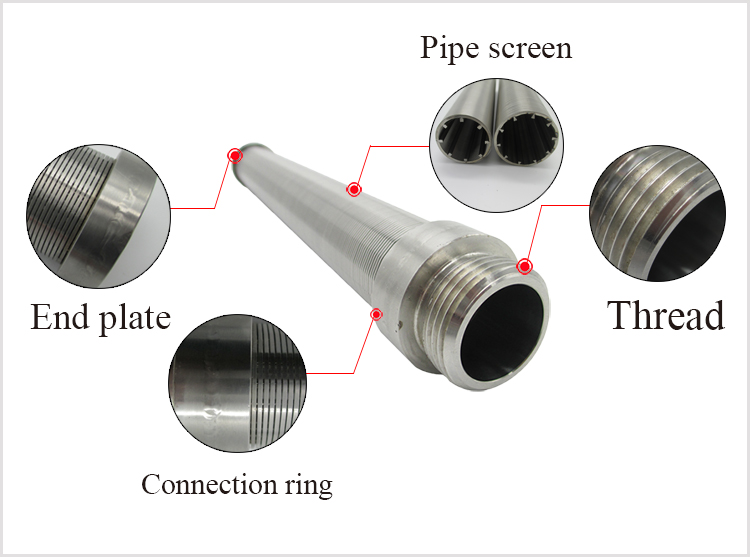

End connection |

Plain beveled ends, flanged or threaded couplings |