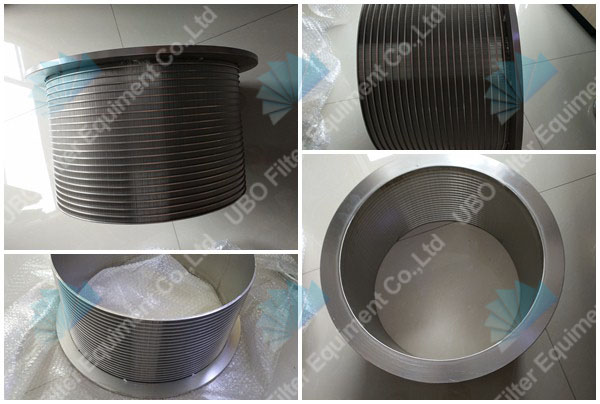

| Category: | Wedge Wire Screen Cylinders |

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request |

| Properties: | wedge wire screen cylinders |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

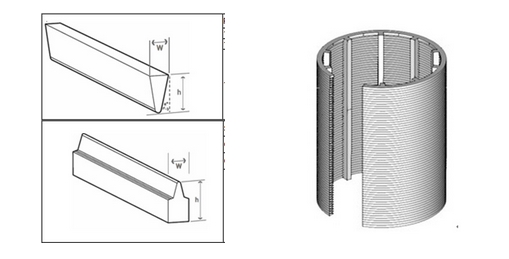

V shaped wire sieving basket as centrifugal liners which require external supports and also self-supporting balanced baskets for the centrifuge manufacturers. These V shaped wire sieving baskets are more complex than the other types of screens requiring extra strength to withstand the stresses of centrifuge dryers. These baskets are typically used in mineral processing for coal, potash, salt, sand, pulp,paper and a variety of chemicals. They are also used for refuse removal from oil and gas drillers.

The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time, Wedge Wire Screen have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. Wedge Wire Screen can be used in many kinds of medium filtering.

1. Many wing pieces, no winding, highly efficient rotary drum type rotor.

2. Pulp consistency can reach 2.5~4%, reduce water consumption and fiber loss of production process.

3. Heavy impurity discharge tube, ensure the security of the sieve drum operation.

4. Advanced structure, strong and durable, easy dismounting, low energy consumption, less wastage fiber.

5. Equipped with automatic oiling and mechanical seal water monitoring device, high degree of automation.

6. Compact structure, small power, high output.

7. 1 year warranty and best after-sale service

|

Outside Diameter

|

Profile

wire

|

Rod

wire

|

Rod

quantity

|

Slot

size

|

Length

|

||

|

DN

|

Inch

|

mm

|

mm

|

mm

|

|

mm

|

mm

|

|

20

|

3/4

|

26.9

|

1.5*2

|

2*3

|

12

|

0.1~0.25

|

45~3000

|

|

25

|

1

|

33.7

|

1.5*2

|

2*3

|

14

|

0.1~0.25

|

45~3000

|

|

32

|

1~1/4

|

42.4

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000

|

|

40

|

1~1/2

|

48.3

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000

|

|

50

|

2

|

60.3

|

1.5*2

|

2*3

|

18

|

0.1~0.5

|

45~3000

|

|

65

|

2~2/2

|

76.1

|

1.5*2

|

2*3

|

20

|

0.1~0.5

|

45~3000

|

|

80

|

3

|

88.9

|

1.8*2.5

|

2*3

|

24

|

0.1~0.5

|

45~3000

|

|

100

|

4

|

114.3

|

1.8*2.5

|

2*3

|

30

|

0.5~2

|

1000~6000

|

|

125

|

5

|

139.7

|

2.3*2.7

|

2*3

|

36

|

0.5~2

|

1000~6000

|

|

150

|

6

|

168.3

|

2.3*2.7

|

3*5

|

44

|

0.5~2

|

1000~6000

|

|

200

|

8

|

219.1

|

3.3*4.5

|

3*4.7

|

56

|

0.5~2

|

1000~6000

|

|

250

|

10

|

273

|

3.3*4.5

|

4*6

|

66

|

0.5~2

|

1000~6000

|

|

300

|

12

|

323.9

|

3.3*4.7

|

4*6

|

72

|

0.5~2

|

1000~6000

|

|

350

|

14

|

355.6

|

3.7*5

|

4*6

|

80

|

0.5~2

|

1000~6000

|

|

400

|

16

|

406.4

|

1.5*2

|

2*3

|

94

|

0.1~2

|

1000~6000

|

|

450

|

18

|

457

|

2*3

|

4*5

|

112

|

0.1~2

|

500~400

|

|

500

|

20

|

508

|

2*3

|

4*5

|

124

|

0.1~2

|

500~400

|

|

550

|

22

|

559

|

2*3

|

4*5

|

140

|

0.1~2

|

500~400

|

|

600

|

24

|

610

|

2*3

|

4*5

|

156

|

0.1~2

|

500~400

|

|

Siot:0.1mm~2mm Tolerance:0.05

|

|||||||