|

wedge wire pipe,Materials: stainless steel 304,316L, low carbon galvanized or as per your request.

Inquiry now

|

Wedge Wire Screen |

|

wire wrapped liner,Materials:stainless steel 304,316L.

Inquiry now

|

Wedge Wire Screen |

|

Stainless Steel Profile Wire Screen,we are a factory of wedge wire screen, if you have picture , we will be drawing for you

Inquiry now

|

Wedge Wire Screen |

|

stainless steel looped wedge wire screen,Material: low carton galvanized steel, stainless steel (304,316) ,Use: waste water treatment,water well.

Inquiry now

|

Wedge Wire Screen |

|

Stainless Steel V Shaped Wire Screens,Material: low carton galvanized steel, stainless steel (304,316) Use: waste water treatment,water well.

Inquiry now

|

Wedge Wire Screen |

|

Wire wrapped stainless steel wedge wire screen meshs are made up of rods and wire. The rod can be round wire, triangular wire or trapezoid wire. The wire is triangular wire (V-shaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time, water well screens have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

Inquiry now

|

Wedge Wire Screen |

|

wedge construction wire,Materials: stainless steel 304,316L, low carbon galvanized or as per your request.

Inquiry now

|

Wedge Wire Screen |

|

Oil screen tube,Material: Low carton, low carton galvanized steel (LCG), stainless steel (304,316etc.)

Inquiry now

|

Wedge Wire Screen |

|

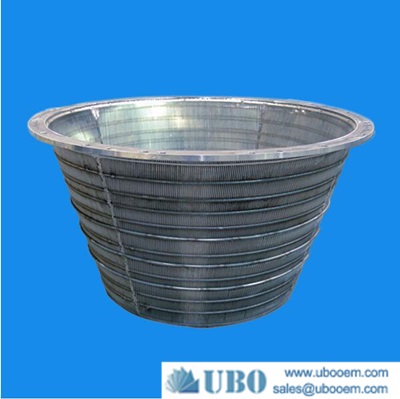

The sieve screen basket liners which require external supports and also self-supporting balanced baskets for the centrifuge manufacturers. These wedge wire screen baskets are more complex than the other types of screens requiring extra strength to withstand the stresses of centrifuge dryers. These baskets are typically used in mineral processing for coal, potash, salt, sand, pulp,paper and a variety of chemicals. They are also used for refuse removal from oil and gas drillers.

Inquiry now

|

Wedge Wire Screen |

|

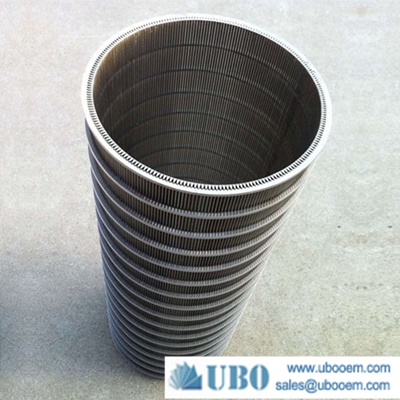

Wedge wire Wedge Wire Screen pipe is manufactured by a V or wedge shaped wire around an internal array of longitudinal support rods. Each intersection point of this wire is fusion welded. The V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water (oil) to enter your well freely in ample quantities while at the same time keeps the majority of sand and gravel out of the well.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Screen Basket is mainly used in centrifuge dewatering,coal,chemical,and metallurgical industries. Screen basket is a key part of centrifuge.It is high-speed rotating parts. When work, the basket should not only bear the vibration load, but also bear the impact of coal and water. So it requires relatively high strength and precision.

Inquiry now

|

Wedge Wire Screen |

|

Stainless steel cylindrical wedge wire screens, also called round slot tube. It is made of stainless steel wire, which is the most popular type because of outstanding chemical stability and corrosion resistance. The stainless steel cylindrical wedge wire screensis composed of working profile and support profile. It is produced on an automotive machine. The support profiles is placed on the suit position of the machine, during the surface profiles are spirally wounding, the support profiles are welded onto the surface profiles

Inquiry now

|

Wedge Wire Screen |

|

reverse rolled screen ,Material: Low carton, low carton galvanized steel (LCG), steel treated with plastic,

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire screen are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.,

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire screen are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

Inquiry now

|

Wedge Wire Screen |

|

Wedge wire water strainer&nozzle is composed of V-profile wire stainless steel which is spirally wrapped in certain equal slot. To maintain the slot size around inside and add extra strength are mounted. It has each cover for both ends of nozzle. Each wire and rod are made by spot welding. and fitting pipe is adjusted according to the thickness of set bottom plate.Nozzle is completed by welding fitting pipe to a cover of down end after setting screw according to the type of nut.,

Inquiry now

|

Wedge Wire Screen |

|

Stainiess steel strainer nozzle is composed of V-profile wire stainless steel which is spirally wrapped in certain equal slot. To maintain the slot size around inside and add extra strength are mounted. It has each cover for both ends of nozzle.Each wire and rod are made by spot welding. and fitting pipe is adjusted according to the thickness of set bottom plate.Nozzle is completed by welding fitting pipe to a cover of down end after setting screw according to the type of nut.

Inquiry now

|

Wedge Wire Screen |

|

Stainless steel filter nozzles manufactured by wrapping a shaped wire around an internal array of longitudinal rods.The wire and rod, generally made from carbon or stainless steel are joined by resistance welding. Screen sections are usually twenty feet long. Commonly referred to as continuous slot or wire wrap screen, this product was originally developed to overcome problems associated with cable tool wells drilled in fine grained.

Inquiry now

|

Wedge Wire Screen |

|

Water wedge wire screen filter nozzle is composed of V-profile wire stainless steel which is spirally wrapped in certain equal slot. To maintain the slot size around inside and add extra strength are mounted. It has each cover for both ends of nozzle.Each wire and rod are made by spot welding. and fitting pipe is adjusted according to the thickness of set bottom plate.Nozzle is completed by welding fitting pipe to a cover of down end after setting screw according to the type of nut.

Inquiry now

|

Wedge Wire Screen |

|

The Wedge Wedge Wire filter nozzle suppliers have a screen pipe. Nozzles are closed on one side and have a threaded fitting on the other. The screen nozzle with thread coupling can be fixed on the filtering equipment for the filteration of water petrol resin and other medium.One rubber shim , one steel shim and two thin nuts of the same material for a nozzle.,

Inquiry now

|

Wedge Wire Screen |