|

UBO offers a multitude of screen configurations and sizes for both internally- fed and externally-fed rotary sieve equipment. Screens are used for effluent solids separation and by-product recovery in a wide variety of municipal and industrial waste water and food processing applications.

Inquiry now

|

Wedge Wire Screen |

|

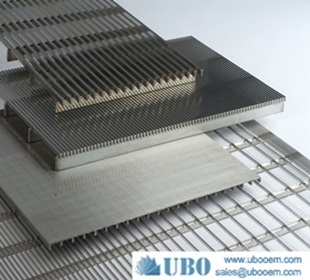

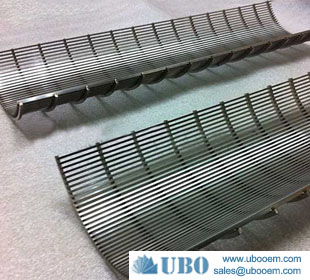

Rotary Sieve Screens is easy to penetrate, having good wear-resisting and corrosion resistance. With Trapezoidal cross-section, even gap, stable welding quality, large opening area, long life time, high strength and high load capacity, it can be made into various shapes. The dimensions, wire diameter, slot and frame structure can be customized.

Inquiry now

|

Wedge Wire Screen |

|

gravity fed boxes are typically applied to make The gravity fed boxes are typically applied to make coarse separations ahead of the degerminators and in multistage germ washing. The system uses a Wedge Wire dewatering screen to retain the solids while allowing effluent to run through the system. The slurry is gravity fed to the head box and flows to the screen. The solids retained from the screen gather for disposal or reuse.

Inquiry now

|

Wedge Wire Screen |

|

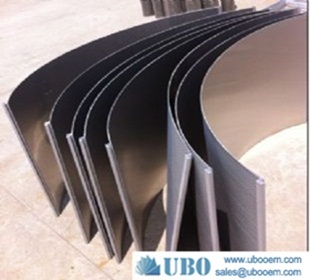

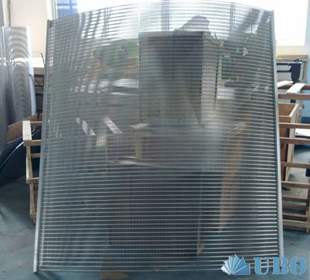

Deep arch Sieve Screens is manufactured by a V or wedge shaped wire around an internal array of longitudinal support rods. Each intersection point of this wire is fusion welded. The V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening

Inquiry now

|

Wedge Wire Screen |

|

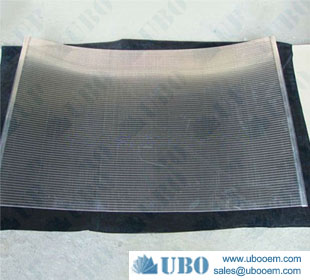

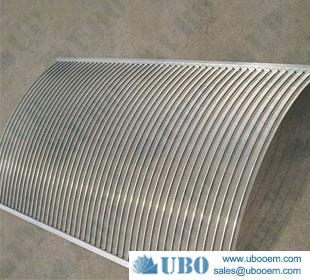

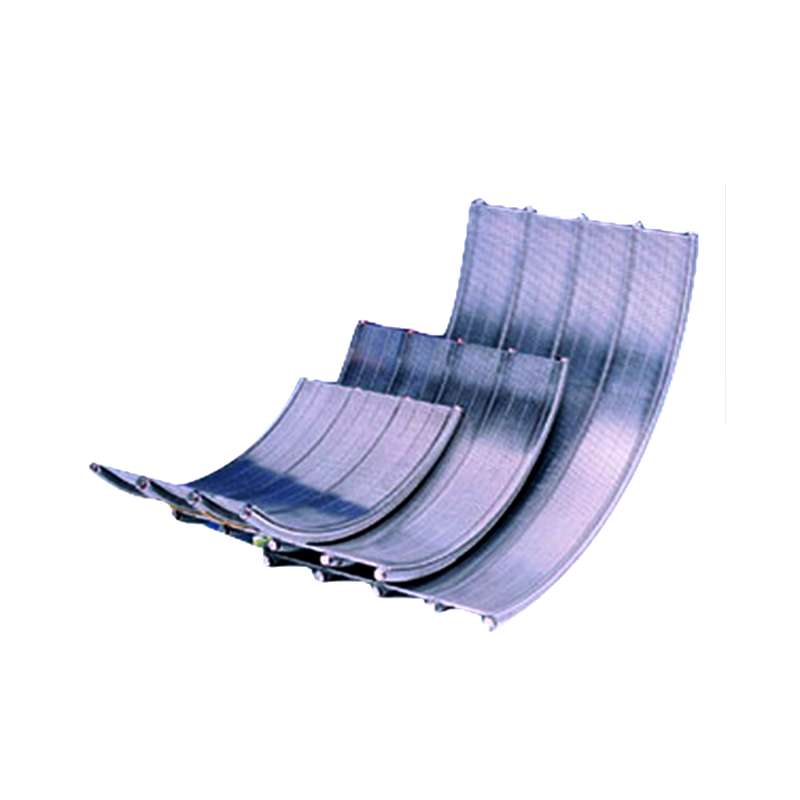

The fine wire sieve bend screen, also known as the wedge wire run down screen, wedge wire side hill screen, DSM screen, Parabolic screen, wedge wire curve screen and so on. The sever bend screen could be custom made and designed according to the application. They are usually used to separate solids from liquids. The curved screen of sieve bend provides greater capacity than flat wedge wire screen due to increased gravitaonal forces on material frowing against the curve.

Inquiry now

|

Wedge Wire Screen |

|

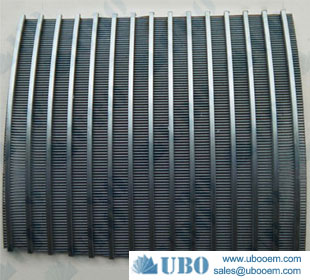

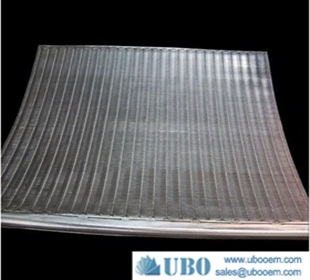

The dewatering capacity of a wedge wire cross-flow sieve panels is primarily influenced by the screen width, the slot opening, and the wire size (width). Installation angle, feed velocity and uniform distribution across the screen are also very important.

Inquiry now

|

Wedge Wire Screen |

|

The dewatering capacity of a wedge wire cross flow sieve bend screen is primarily influenced by the screen width, the slot opening, and the wire size (width). The chart below shows typical dewatering capacities in US gallons per minute (GPM) per foot of screen width.

Inquiry now

|

Wedge Wire Screen |

|

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media in dewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media indewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

Vibrating screen consumes big quantity of wedge wire.

Inquiry now

|

Wedge Wire Screen |

|

Sieve Bend Screens have another name as DSM sreens because the Dutch State adapts sieve bend in mine development first. Sieve bends are manufactured to suit a wide range of industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Widely used for fiber removal in Starch industry.

Inquiry now

|

Wedge Wire Screen |

|

oil vibration sieve screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.,A oil vibration sieve screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.,oil vibration sieve screens are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.

Inquiry now

|

Wedge Wire Screen |

|

The stainless steel test sieve is applied to exact mesh analysis, test, measure, classification for powdery material in lab, hospital, pharmacy, foodstuff, metallurgy, construction departments,etc.

Inquiry now

|

Wedge Wire Screen |

|

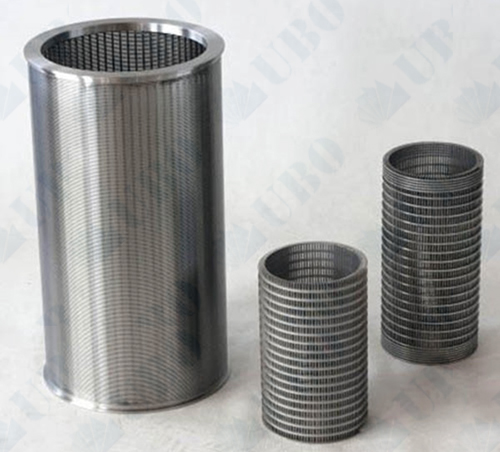

Sieve Cylinder Filter is a metal mesh filter for screening structural elements. Widely used in many ,industries in the screening, filtration, dehydration, removing mud and other operations. It has ,high strength, stiffness and load capacity, can be molded into the shape.

Inquiry now

|

Stainless Steel Filter Element |

|

Tapioca Starch Vibrating Sieve is a specialized equipment designed to enhance the quality and efficiency of tapioca starch production.

Inquiry now

|

News&Trends |

|

Wedge Wire Arc Curved Screen Plate is called Wedge Wire wedge wire hillside screen ,sieve bend screen and DSM screen etc

Inquiry now

|

Stainless Steel Filter Element |

|

The china aquaculture wedge wire sieve filter is not only high in quality but also low in price, and very cost-effective. It is widely sold all over the world. Let”s see.

Inquiry now

|

News&Trends |

|

Wedge wire mesh screen is an indispensable production tool in the process of food production and processing. So let’s take a look at the role of wedge wire sieve in the grain industry today.

Inquiry now

|

News&Trends |

|

Even in the business of manufacturing and supplying vibratory sieving and screening equipment, the terms ‘sieve’ and ‘screen’ are pretty interchangeable, but technically speaking, there is a difference.

Inquiry now

|

News&Trends |

|

The sieve bend screen is one of the fine screening equipment used in the treatment plant.

Inquiry now

|

News&Trends |