|

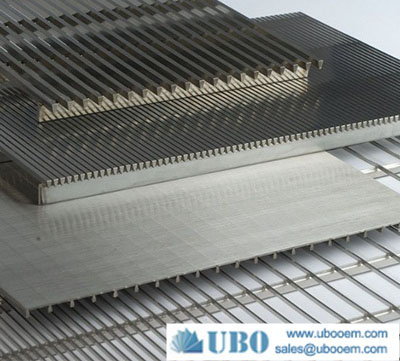

UBO supply numerous combination of Dewatering Screens for static dewatering equipments. The dewatering Screens has gravidity feed. The solid particles and the liquid are separated on a bend or folded wedge wire screen. The liquid flow through the panel screen, although the solid particles roll down.

Inquiry now

|

Wedge Wire Screen |

|

Screw presses are used in a wide variety of dewatering applications, often in the same applications as belt presses, centrifuges, and filter presses. The screw press is a simple, slow moving mechanical device. Dewatering is continuous and is accomplished by gravity drainage at the inlet end of the screw and then by reducing the volume as the material being dewatered is conveyed from the inlet to the discharge end of the screw press.

Inquiry now

|

Wedge Wire Screen |

|

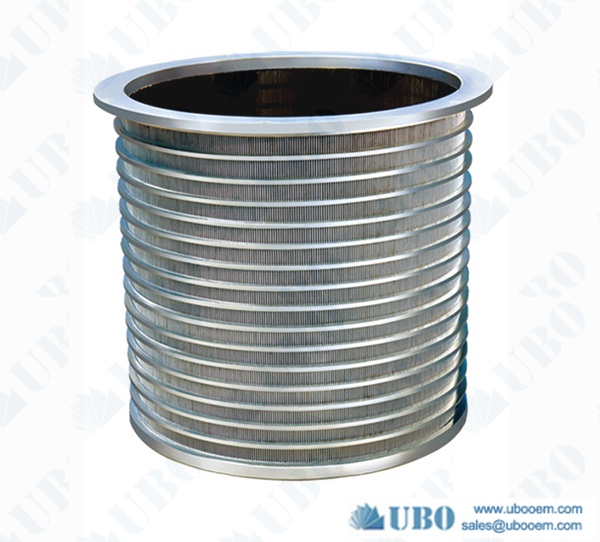

Deep arch Sieve Screens is manufactured by a V or wedge shaped wire around an internal array of longitudinal support rods. Each intersection point of this wire is fusion welded. The V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening

Inquiry now

|

Wedge Wire Screen |

|

UBO manufactures a variety of Sidewall Screens used in the sugar industry – including sidewall tower and cossette mixer screens. These high quality, long lasting screens are looped wedge wire constructed to provide the ultimate value to the market.,

Inquiry now

|

Wedge Wire Screen |

|

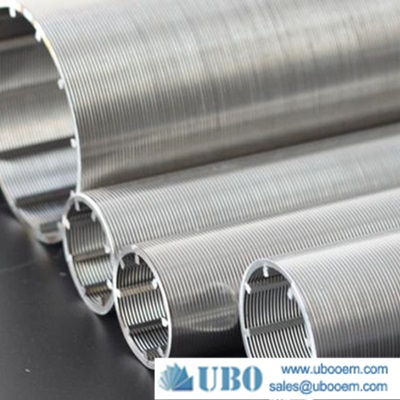

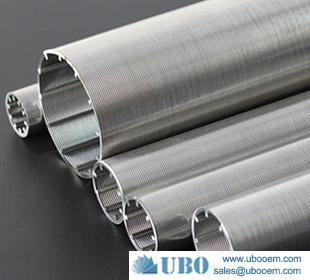

Water well stainless steel sand free screen is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights.

Inquiry now

|

Wedge Wire Screen |

|

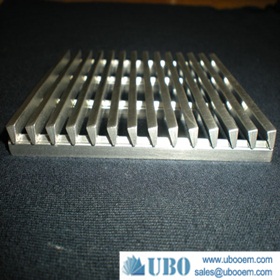

UBO high quality custom built flat panel wedge wire screens, manufactured either framed or unframed with a variety of support rods, offers a high strength, long lasting, economical solution to the market. They come in commonly shaped wedge wire profiles and offer good screening efficiency across a wide range of applications. Flat wedge wire screens are excellent for use to de-water, de-slim, drain and rinse, wet classify, dry classify, filter, dry and cool. They are recommended for use in any application that requires efficient liquid-solid separation.

Inquiry now

|

Wedge Wire Screen |

|

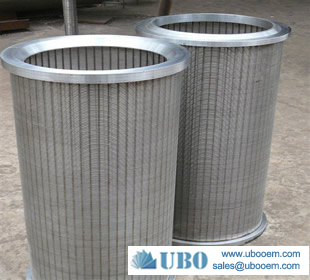

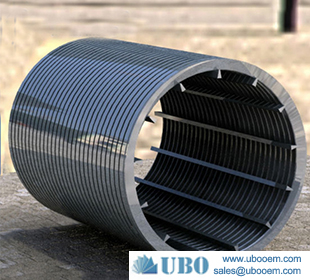

Chip Wringer Oil Screens support cores is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine. Each profile wire and support rod is welded by resistance welding.

Inquiry now

|

Wedge Wire Screen |

|

TheFish Protection Screens System design utilizes low velocity flow(typically < 1/2 fps) through the wedge wire screen surface which minimizes impingement and danger to aquatic life.,Profile wire fish screens prevent entrainment, injury, or death of the targeted aquatic species by physically precluding fish from entering a water intake.

Inquiry now

|

Wedge Wire Screen |

|

The lauter tun wedge wire screen allows the solid grain components of the mash to act as a filter to separate the wort.

Inquiry now

|

Wedge Wire Screen |

|

YUBO is one of the leading wedge wire screen manufacturers/suppliers. Our water intake screens have high quality and competitive prices.

Inquiry now

|

Wedge Wire Screen |

|

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media in dewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

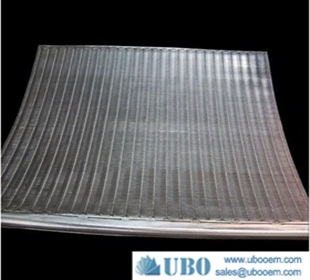

Crimped wire screen can withstand the rigorous treatment and survive the day and night attrition experienced in quarries, sand and gravel pits and all types of ore treatment.,Atlas crimped screen is renowned for their extremely high resistance to abrasion. Close checks on raw materials, production processes and constant quality control at all stages of manufacture guarantee a top quality finished product.,

Inquiry now

|

Wedge Wire Screen |

|

Run down screens offer a high capacity, cost effective method of solids/liquids separation utilizing stainless steel wedge wire as the screening medium.

Inquiry now

|

Wedge Wire Screen |

|

Stainless steel Wedge Wire oil well screen filter tubes have become the predominant screen type in the water well industry.

Inquiry now

|

Wedge Wire Screen |

|

Woven wedge wire screens supplied by Atlas feature precise profile shapes and slot spacing which mean greater open area and reliable slot openings.

Inquiry now

|

Wedge Wire Screen |

|

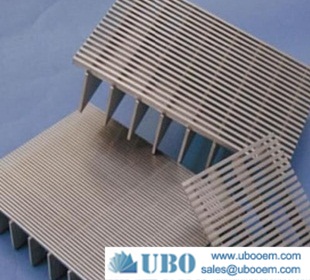

Sieve Bend Screens have another name as DSM sreens because the Dutch State adapts sieve bend in mine development first. Sieve bends are manufactured to suit a wide range of industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Widely used for fiber removal in Starch industry.

Inquiry now

|

Wedge Wire Screen |

|

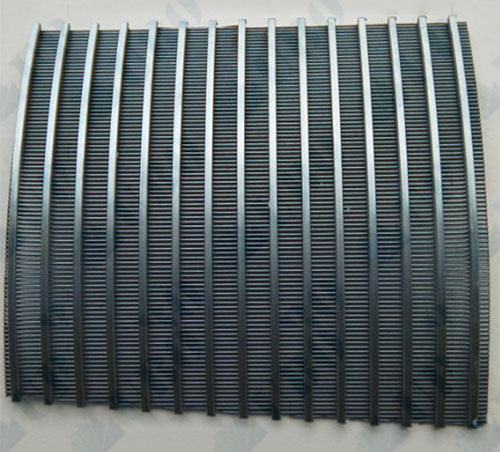

Welded wedge wire screen is manufactured by flat welded screen in panel or cylinder type. ,Flat welded wedge wire panels offer a perfectly flat and smooth surface with rectangular openings,

Inquiry now

|

Wedge Wire Screen |

|

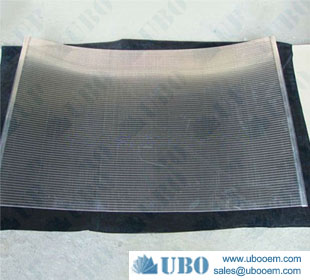

oil vibration sieve screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.,A oil vibration sieve screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.,oil vibration sieve screens are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.

Inquiry now

|

Wedge Wire Screen |

|

wedge wire arc screen has a wide range of applications in the field of process, engineering such as sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals etc.

Inquiry now

|

Wedge Wire Screen |

|

stainless steel Water treatment products water filters is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). It has a structure and high open area, as well as accurate slot dimension.,

Inquiry now

|

Wedge Wire Screen |