|

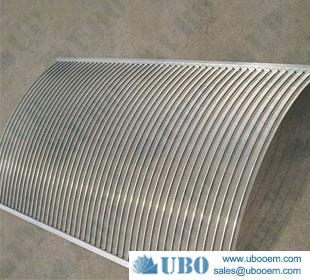

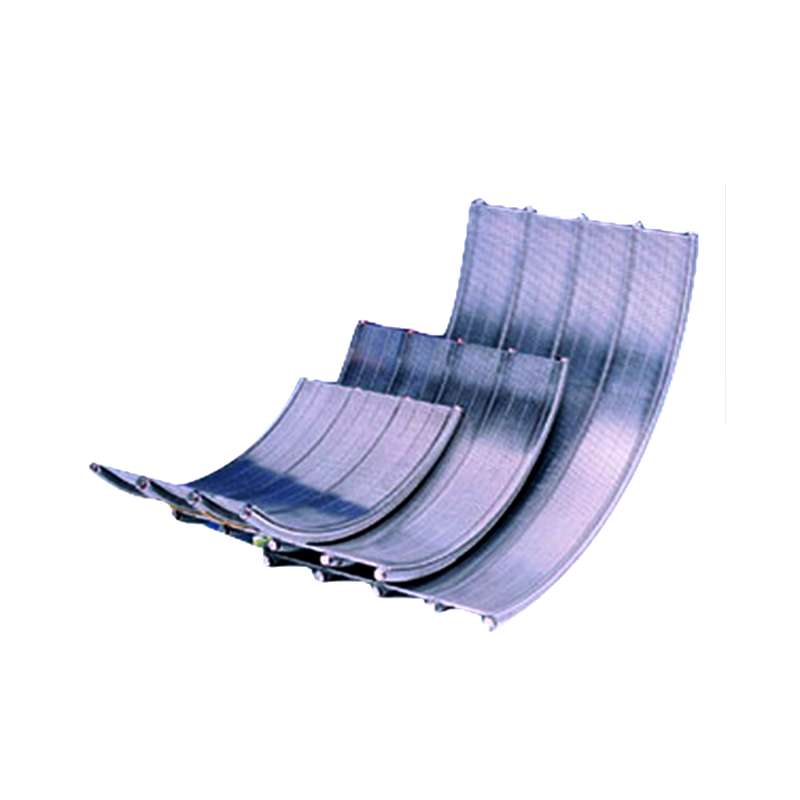

The fine wire sieve bend screen, also known as the wedge wire run down screen, wedge wire side hill screen, DSM screen, Parabolic screen, wedge wire curve screen and so on. The sever bend screen could be custom made and designed according to the application. They are usually used to separate solids from liquids. The curved screen of sieve bend provides greater capacity than flat wedge wire screen due to increased gravitaonal forces on material frowing against the curve.

Inquiry now

|

Wedge Wire Screen |

|

The dewatering capacity of a wedge wire cross flow sieve bend screen is primarily influenced by the screen width, the slot opening, and the wire size (width). The chart below shows typical dewatering capacities in US gallons per minute (GPM) per foot of screen width.

Inquiry now

|

Wedge Wire Screen |

|

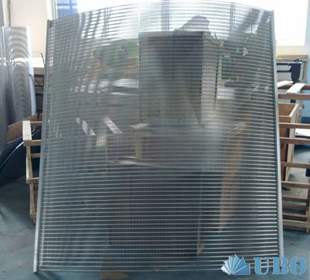

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media in dewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

Curved (rolled) wedge wire screen is utilized as conveyor and auger screening media indewatering applications. Wedge wire conveyor / auger screens usually have axial wires and are half cylinders. Other configurations are also produced.

Inquiry now

|

Wedge Wire Screen |

|

Sieve Bend Screens have another name as DSM sreens because the Dutch State adapts sieve bend in mine development first. Sieve bends are manufactured to suit a wide range of industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Widely used for fiber removal in Starch industry.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Arc Curved Screen Plate is called Wedge Wire wedge wire hillside screen ,sieve bend screen and DSM screen etc

Inquiry now

|

Stainless Steel Filter Element |

|

The sieve bend screen is one of the fine screening equipment used in the treatment plant.

Inquiry now

|

News&Trends |

|

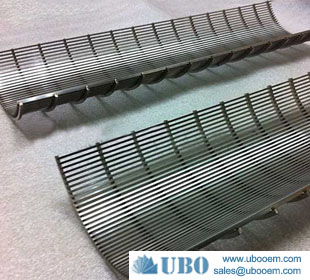

Wedge wire screen arc sieve bend screen plate consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow.

Inquiry now

|

Wedge Wire Screen |

|

Sieve bend arc screen wedge profile wire screem filter plate for wastewater treatment is a screen surface for the arc to open away from wet fine screening equipment.

Inquiry now

|

Wedge Wire Screen |

|

The Looped wire sieve bend screen panel for food processing of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire wedge v wire sieve bend curved screen plate also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens, can be custom designed to separate solids from liquids in various applications including food processing, pulp and paper, waste water cleanup, surface water intakes, corn wet milling, coal preparation, and gold recovery.

Inquiry now

|

Wedge Wire Screen |

|

Using a sieve bend screen eliminates the risk of stringing and of plugging the water nozzles.

Inquiry now

|

Wedge Wire Screen |

|

It is manufactured by a v or wedge shaped wire around an internal array of longitudinal supportrods. Each intersecting point of these wire is fusion welded.

Inquiry now

|

Wedge Wire Screen |

|

Sieve bend screen also called curved screen or arc screen. The working principle and the structures of the screen helps a lot in many fields.

Inquiry now

|

News&Trends |

|

Wedge Wire v wire water well bending v wire curve screen panel consist of shape profile wire and the longitudinal support rods. Each intersecting point the Vshape section plane can avoid blockage ,and make sure of the unimpeded water. The consecutive slot have more open area ,and it can reduce the speed of the water entering to of these wires is fusion welded ,so it has sturdy constriction and good mechanical property. Avoid the sand entering the screen under the great pressure ,so it can filter sand better.

Inquiry now

|

Wedge Wire Screen |

|

Wedgewire panels have a high open area by comparison with woven wire screen media. Supplied in mainly flat forms or curved panel forms. High opening screen gives lower entrance velocities and higher flow rates through the screen. In the case of pump in-taking screens, pumping costs are lower.

Inquiry now

|

Technical Information |

|

UBO wedge wire screen curved plate can be used in a variety of applications ranging from classifying to recovering usable products that would end up in sewer lines to capturing solids from effluents. A continuous slot screen sieve bend gives you a great amount of open area, is significantly more affordable and requires less maintenance than vibrating or rotary drum options.

Inquiry now

|

Wedge Wire Screen |

|

A sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface

Inquiry now

|

Wedge Wire Screen |

|

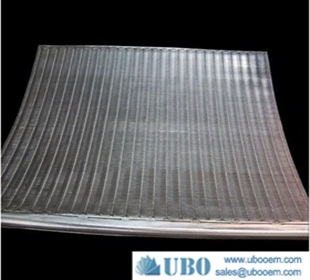

Stainless steel wedge wire sieve bend screen panel can be fabricated in a range of both flat panels and tubes. Wedge-wire and support profiles are resistance welded with accurate slot dimensions. The screens can be mechanically and electropolished, and given additional surface hardening treatments.

Inquiry now

|

Wedge Wire Screen |

|

Sieve plate is easy to penetrate, having good wear-resisting and corrosion resistance. With Trapezoidal cross-section, even gap, stable welding quality, large opening area, long life time, high strength and high load capacity, it can be made into various shapes. The dimensions, wire diameter, slot and frame structure can be customized.

Inquiry now

|

Wedge Wire Screen |