|

The Passive Intake Screens can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication.

Inquiry now

|

Wedge Wire Screen |

|

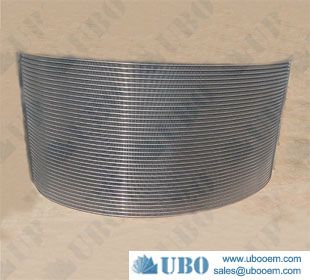

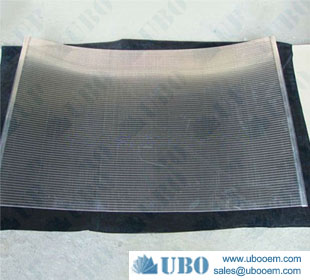

Gravity Fed Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.,Gravity Fed Screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Inquiry now

|

Wedge Wire Screen |

|

gravity fed boxes are typically applied to make The gravity fed boxes are typically applied to make coarse separations ahead of the degerminators and in multistage germ washing. The system uses a Wedge Wire dewatering screen to retain the solids while allowing effluent to run through the system. The slurry is gravity fed to the head box and flows to the screen. The solids retained from the screen gather for disposal or reuse.

Inquiry now

|

Wedge Wire Screen |

|

The Profile Wire Screen element included with the main housing as depicted below eliminates the migration and loss of expensive resin/media, whilst at the same time protecting your pumping equipment. A combination of different Profile Wire sizes and slot openings can be used depending on your circumstances. Completion Products will also determine the effective screen open area in order to improve upon efficiency and minimise the pressure drop.,In the event that there is resin/media build up with the Resin Trap Screen assembly, an increase in the pressure drop will result and if one is installed, the resin/media will be visible through the “sight glass”.

Inquiry now

|

Wedge Wire Screen |

|

The dewatering capacity of a Wedge Flapper Screens is primarily influenced by the screen width, the slot opening, and the wire size. Installation angle, feed velocity and uniform distribution across the screen are also very important.

Inquiry now

|

Wedge Wire Screen |

|

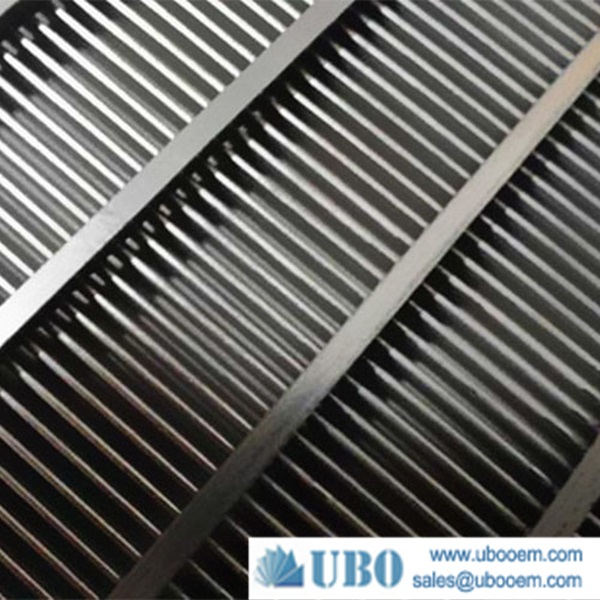

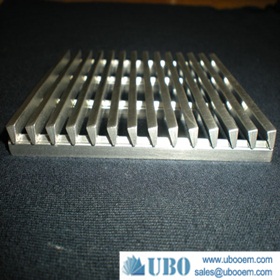

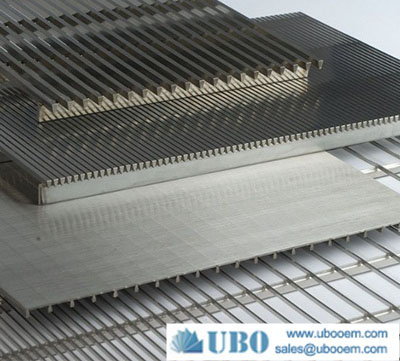

Stainless steel flat wedge screen panel is made of V shaped rod or Convex shape wire with an unique welding process, offering great strength precision ,long service life.

Inquiry now

|

Wedge Wire Screen |

|

Fine mesh woven wire cloth is used in thousands of applications requiring small particle size screening, sorting, sieving, classifying, sizing and separating. Fine mesh screens may be provided complete with screen-edge treatments.

Inquiry now

|

Wedge Wire Screen |

|

Fully welded Wedge Wire flat screens are used for dewatering, sizing, media recovery, and classification. Rigid flat panels are resistance-welded at every wire and support rod juncture.

Inquiry now

|

Wedge Wire Screen |

|

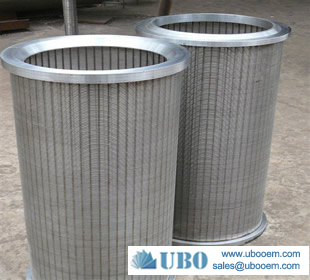

Ubo centrifugal screen baskets are the strongest and most robust in the mineral processing industry. The baskets are built to exacting specifications and quality standards. There are models to suit most centrifugal dryers. Screen wires are welded to support rods at every junction to ensure strong, rigid construction.

Inquiry now

|

Wedge Wire Screen |

|

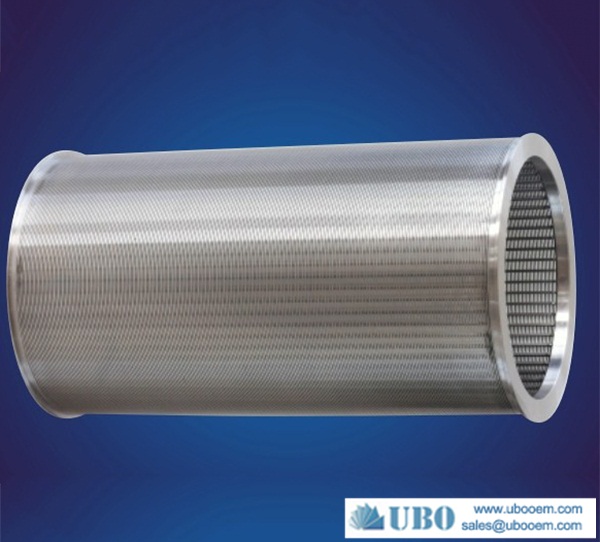

Wedge Wire Screening Systems is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine.

Inquiry now

|

Wedge Wire Screen |

|

Wedge Wire Screen Panels are used in the filtration industry,dewatering,desliming,jigging machines,sieve bend,wedge wire grating and vibrating screens.

Inquiry now

|

Wedge Wire Screen |

|

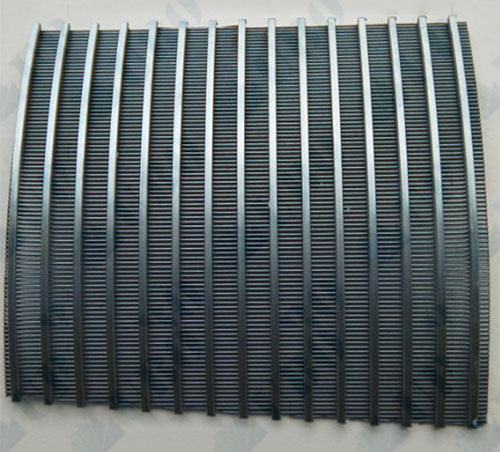

Wedge Wire Screens column covers are made of SS V shaped and SS V shaped or SS V shaped and SS rod or SS V shaped and SS Convex shaped rod with the unique computer controlled machinery in which a continuous length of profile wire of a triangular section is fusion welded into support rods. This V shaped profile wire is wound around the support rods over the full length of the screen thus creating a continuous slot opening.

Inquiry now

|

Wedge Wire Screen |

|

Profile wire Screens consist of V-shape profile wire and the longitudinal support rods. each intersecting point of these wires is fusion welded. So Profile wire Screens has sturdy constriction and good mechanical property. The V-shape section plane can avoid blockage, and make sure of the unimpeded water. The continuous slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so Profile wire Screens can filter sand better. Meanwhile ,the slot size can be changed according to the real condition of the customer requirements

Inquiry now

|

Wedge Wire Screen |

|

stainless steel static wedge wire screen panels for ventilation is made by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods under automatic wire screen machine, then be made to screen panel through cutting and edge welding. Each profile wire and support rod is welded by resistance welding.,

Inquiry now

|

Wedge Wire Screen |

|

UBO supply numerous combination of Dewatering Screens for static dewatering equipments. The dewatering Screens has gravidity feed. The solid particles and the liquid are separated on a bend or folded wedge wire screen. The liquid flow through the panel screen, although the solid particles roll down.

Inquiry now

|

Wedge Wire Screen |

|

Screw presses are used in a wide variety of dewatering applications, often in the same applications as belt presses, centrifuges, and filter presses. The screw press is a simple, slow moving mechanical device. Dewatering is continuous and is accomplished by gravity drainage at the inlet end of the screw and then by reducing the volume as the material being dewatered is conveyed from the inlet to the discharge end of the screw press.

Inquiry now

|

Wedge Wire Screen |

|

Vibrating Screen Panels consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

Inquiry now

|

Wedge Wire Screen |

|

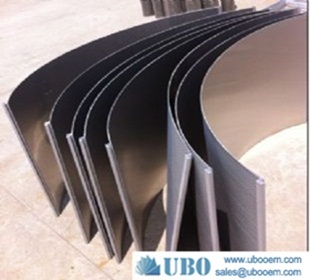

Deep arch Sieve Screens is manufactured by a V or wedge shaped wire around an internal array of longitudinal support rods. Each intersection point of this wire is fusion welded. The V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening

Inquiry now

|

Wedge Wire Screen |

|

UBO manufactures a variety of Sidewall Screens used in the sugar industry – including sidewall tower and cossette mixer screens. These high quality, long lasting screens are looped wedge wire constructed to provide the ultimate value to the market.,

Inquiry now

|

Wedge Wire Screen |

|

Water well stainless steel sand free screen is made by winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights.

Inquiry now

|

Wedge Wire Screen |