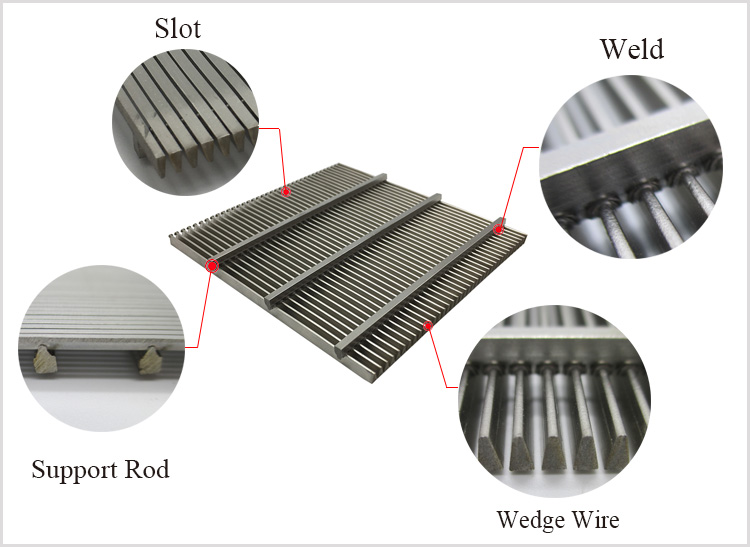

UBO is a wedge wire screen suppliers which can provide wholesale wedge wire screen products which are made from V shaped profile wire, with an unique welding process, offering great strength, precision, long service life and a wide range of applications in the field of process, engineering such as sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals. And the Wedge Wire wedge wire sieve screen offer a perfectly flat and smooth surface with rectangular openings.This kind of wedge wire scren can can be used in a wide range of applications — including filtration, extraction, dehydration, fluidized bed, absorption, sorting and sifting, solid or water separation, cleaning, rinsing, drying, sizing, recycling and transport — in the processing of meat and poultry, sugar, fruits and vegetables, and beverages. Our professionals are happy to help you determine the most effective, efficient processes and screens for your particular needs. UBO wedg wire screens can meet the needs of the food and beverage industry with their abilities to withstand pressure, effectively filter and extract, prevent plugging and simplify maintenance. Beyond that, the type of screen you use depends on the specific food or beverage you manufacture.

Lateral Strength

Increases rapidly with the width of the profile and sufficient is needed to avoid the likelihood of the wedge wire screens being bent sideways and the accuracy of the slot being thereby lost.

Easy Clearing

The narrowest part of the aperture comes at the top and the steady opening out from that point promotes easy clearing.

Load Carrying Capacity Or Vertical Strength

Increases rapidly with the depth of the profile. And it is needed to a greater degree than is lateral strength.

Percentage Open Area

For any given aperture size, this depends on the number of apertures per foot width of screen. The wider the profile, the fewer the apertures, and the less is open area. Like that the smaller the number of pressed wedge wires per foot, the greater the open area.

Better Sand Filtration

Due to specialize manufacturing process, wide range of slot opening is available down to 0.15mm to allow proper slot selection depending upon the size of sand in particular area. This gives better sand control and reduced pump maintenance and longer tube well life.

Wearing Life

With abrasive materials the top surface of the profile becomes worn away and inevitably the aperture must increase. With a small angle of opening the increase is gradual, but with a large angle it is rapid. The apertures quickly reach the oversize limit and the working life is reduced.

Energy Saving

Due to reduce frictional head losses and increased discharge, the pump load reduces the power required to pump same quantity of water. Power saving of around 20-25% is observed.

Non Clogging Slots

V-Shape wire which gives inwardly widening V-Shape slots. This shape doesn’t give space for any sand particle to get stuck inside the slot and these screens are non clogging. Hence, the efficiency of tube well isn’t reduced over years due to clogging.