In the world of fluid handling, ensuring the smooth and efficient operation of pumps and downstream equipment is paramount. Unwanted solids and debris flowing through pipelines can wreak havoc, causing damage, increasing downtime, and leading to costly repairs.

This is where Inline Basket Strainers play a vital role.

An Inline Basket Strainer is a crucial filtering device typically installed on the suction side of a pump. Its primary function is straightforward but critical: to remove solid particles or debris from a liquid flow.

These particles, often large enough to be seen with the naked eye, could otherwise damage sensitive equipment like pumps, meters, valves, or other components within the system.

Essentially, Inline basket strainers act as a coarse filter, capturing larger contaminants. For finer particles requiring more precise filtration, dedicated filters are generally employed further down the line.

The working principle of an inline basket strainer is elegantly simple yet effective. Key components include:

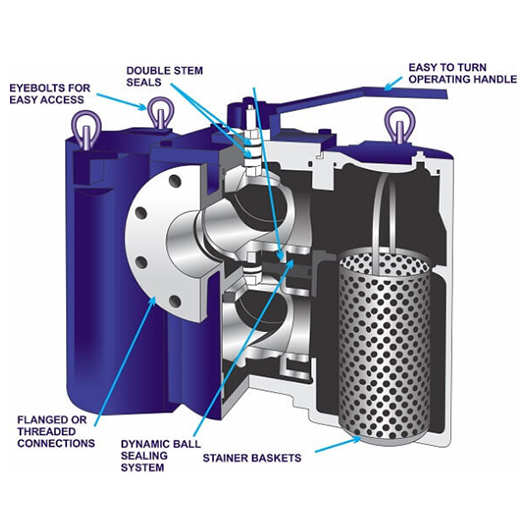

Housing (Casing): The main body of the strainer, featuring an inlet and an outlet for fluid passage.

Basket (Filter Element): Housed within the casing, this removable basket is typically made from perforated metal or wire mesh. The size of the openings in the mesh determines the smallest particle size the strainer will capture.

Top Cover: Seals the top of the housing, providing access to the basket for cleaning or replacement. Covers can be bolted down and may be solid or clear (allowing visual inspection of basket contents).

Optional Drain: Many housings incorporate a drain plug at the bottom. Since trapped solids tend to settle due to gravity, this allows for easy purging and removal of accumulated debris.

The Process: Fluid enters the strainer through the inlet, flows through the mesh basket, and any solids larger than the mesh openings are trapped inside the basket. The cleaned fluid then exits through the outlet, continuing its journey through the system, now protected from potentially damaging debris.

While the core function remains the same, basket strainers come in several designs, each suited for different applications and requirements:

Characteristics: Named for their distinctive shape, Y-Type strainers are often the most economical and compact option. A major advantage is their versatile mounting capability – they can be installed in either horizontal or vertical pipelines (with the draining leg pointing downwards).

Construction: Typically cast as a single piece, giving them excellent pressure tolerance.

Consideration: Due to their design geometry, Y-Type strainers generally introduce a higher pressure drop across the strainer compared to other types. They also tend to have a smaller debris-holding capacity.

Characteristics: Simplex strainers are designed for larger pipe sizes and applications where higher flow rates or larger amounts of debris are expected. They feature a significantly larger, vertically oriented basket within a larger housing.

Benefits: The increased surface area of the basket leads to a lower pressure drop and greater debris-holding capacity. Maintenance is often simplified thanks to a removable lid that allows easy access to the basket for cleaning without needing to drain the entire pipeline.

Limitation: Simplex strainers are generally restricted to horizontal installation only.

Characteristics: Duplex strainers are essentially two Simplex strainers integrated into one unit with diverting valves (like ball or plug valves). This ingenious design allows continuous, uninterrupted operation.

Key Advantage: While one basket is in service filtering the fluid, the flow can be diverted to the second basket. This allows the first basket to be taken offline for cleaning or maintenance without ever stopping the process flow – crucial for critical applications where downtime is unacceptable.

Design: Similar in principle to Simplex strainers regarding capacity and low pressure drop, but with the added benefit of redundancy and continuous flow.

Installing the right basket strainer offers significant benefits:

Equipment Protection: Prevents damage to pumps, meters, nozzles, and other sensitive components.

Reduced Downtime: Minimizes costly interruptions caused by debris-related equipment failure.

Improved Process Efficiency: Ensures cleaner fluid, contributing to optimal system performance.

Lower Maintenance Costs: Protects downstream equipment from wear and tear, extending its lifespan.

Inline Basket Strainers are indispensable components in countless fluid handling systems across various industries. By effectively removing unwanted solids, they safeguard valuable equipment, prevent process interruptions, and contribute to overall operational efficiency. Understanding the different types – Y-Type, Simplex, and Duplex – allows you to select the most appropriate design based on your specific application needs, flow conditions, maintenance requirements, and budget.