One of the initial steps a wastewater treatment plant takes is to run water through a static screen. If your plant is not undergoing this preliminary treatment step, it may be worth considering as it is a cost-effective way to start wastewater treatment.

In wastewater treatment plants, the Static Screen filter is used for pre-treatment. It is used for both municipal and industrial applications, particularly for screening fibrous and non-greasy solids.

1. Static screens are essential for removing solids in wastewater treatment.

2. Proper design and installation are crucial for screen efficiency.

3. Maintenance of static screens is minimal but essential for performance.

When wastewater flows into a treatment plant, a static screen is in front of the remaining wastewater equipment. Wastewater enters the system, passing through a stationary static screen first to remove as many solids as possible.

In addition to a municipal wastewater treatment system, static screens benefit businesses that need to pre-treat industrial wastewater. The list includes companies such as chemical processing plants, paper mills, breweries, food processing plants, and plastic and metal processing plants.

If you have a stormwater system, the static screens are fantastic for removing plastics, trash, and fallen sticks and branches after a storm.

There are various types of static screens,there is primary one type most commonly used by most plants:

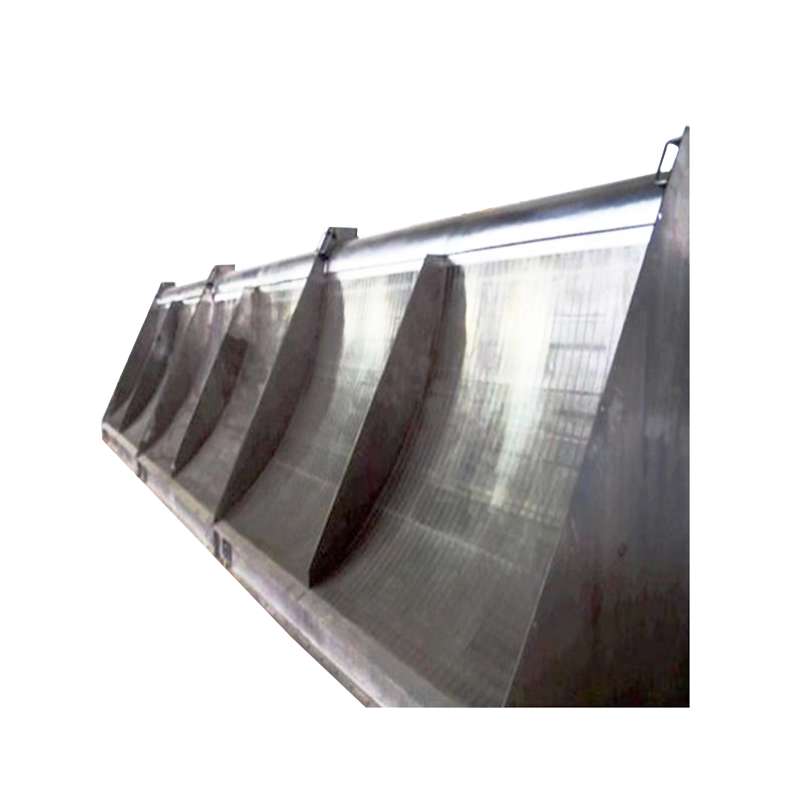

Wedge wire screens are self-supporting and either a cylinder or flat panel. Wastewater travels onto the panel or cylinder and falls through the mesh, while solids go over the top to the collection area. It’s usually made from stainless steel due to its durability and anti-corrosion qualities.

The static screen is equipped with a curved bend screen.

The system allows water fall through the screen and keep solids by sliding down in the collecting area.With the equipment is working alone without continuous maintenance.The design make the machine economic thanks to a zero energy consumption.

1. How do static screens function in wastewater treatment plants?

Static screens in wastewater treatment plants remove large solids and debris from the water by allowing the liquid to flow through the screens while trapping the solids.

2. What are the advantages of using wedge wire static screens in wastewater management?

Wedge wire static screens are known for their efficiency in solids removal, low maintenance requirements, and durability, making them a value-adding component in wastewater management.

3. How do the operational characteristics of bar screens differ from fine screens in wastewater processing?

Bar screens are a type of coarse screen that typically has larger openings to remove bigger solids, while fine screens have smaller openings to capture finer particles in the wastewater.

4. What types of screens are commonly employed in the treatment of water and wastewater, and how do they vary?

The treatment of water and wastewater utilizes various types of screens, such as coarse screens, fine screens, and micro screens, each differing by the size of particles they are designed to remove.

5. What factors should be considered when selecting screens for wastewater treatment facilities?

When selecting screens for wastewater treatment facilities, factors like the size and type of debris to be removed, flow rates, and ease of maintenance should be carefully considered for optimal operation and efficiency.