In the field of well completion and water filtration, pipe base screens are a versatile and efficient solution. These Pipe Base Screens, combining the hydraulic efficiency of a continuous slot wedge wire screen with the robustness of a pipe, are ideal for a variety of demanding environments.

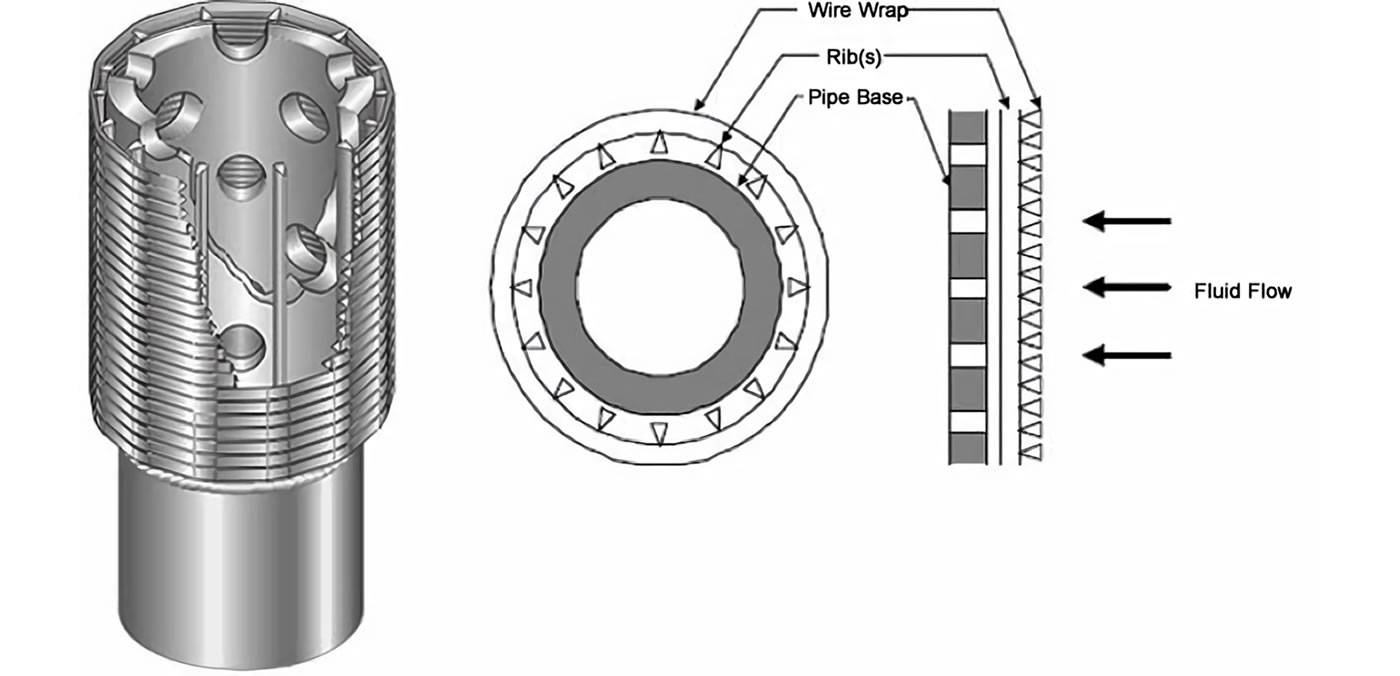

A pipe base screen is essentially a combination of a wrap wire screen pipe and a perforated or slotted base pipe. This dual-layer design is known for its reliability in deep vertical wells and long horizontal remediation of supply wells. The base pipes, which can be made from stainless steel or API 5CT carbon steel casing, are meticulously inspected and cleaned to ensure there are no burrs or imperfections. The screen and pipe are welded together to create a durable and reliable unit that can withstand high collapse pressures and longitudinal constraints.

The Wrapped Wire Screen is a critical component of the pipe base screen. Keystone-shaped wires are helically wrapped around vertical ribs, with each point of contact welded for added strength. This specific design minimizes the risk of sand plugging the screen, promotes self-cleaning, and reduces flow friction. The diameter and number of support rods are tailored to meet the screen's strength and size requirements.

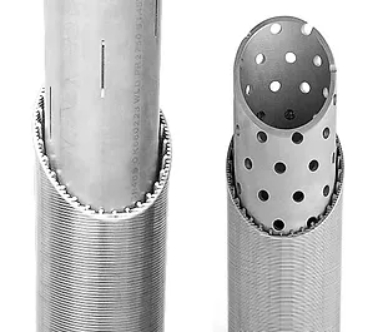

The base pipe screen can be either perforated or slotted, depending on the application needs. Perforated pipes feature circular holes, while slotted pipes have elongated slots. Both types are visually inspected and cleaned to remove any burr material, ensuring a smooth and efficient operation.

1. Reliable Sand Control: Pipe-based screens provide superior sand control, reducing the risk of sand plugging and ensuring optimal well performance.

2. Mechanical Strength: The combination of a wire-wrapped jacket and a perforated pipe provides exceptional mechanical strength, making it an ideal solution for high-collapse resistance applications.

3. Corrosion and Erosion Resistance: Pipe-based screens are designed to withstand the harsh conditions of oil and gas production, offering excellent resistance to corrosion and erosion.

4. Maximized Production: With a larger inflow area, pipe-based screens maximize production, making them an attractive option for operators seeking to optimize well performance.

Pipe base screens are suitable for both casing pipe and open hole environments. Their versatility makes them ideal for a variety of well-configured installations.

These screens can be used in standalone or in combination with gravel-packed completions. Their robust design ensures reliable performance in both scenarios.

Pipe base screens are particularly effective in vertical or horizontal wells that are free from sand. Their design minimizes the risk of sand entering the well, ensuring smooth and efficient operation.

Pipe-based screens offer a unique combination of hydraulic efficiency, mechanical strength, and corrosion resistance, making them an attractive option for oil and gas operators. With their ability to provide reliable sand control, maximize production, and withstand harsh operating conditions, pipe-based screens are the ultimate solution for optimal well performance.

Pipe base screens offer a reliable, efficient, and durable solution for well completion and water filtration. Their unique design combines the hydraulic efficiency of wire-wrapped screens with the mechanical strength of a pipe, making them ideal for a variety of demanding applications.

For more information on how pipe base screens can enhance your operations, feel free to contact us at YUBO today.

Emails: sales@ubooem.com