The DSM Screen (Dutch State Mines Screen or sieve bend screen) represents a pinnacle of engineering in solid-liquid separation technology. Designed with a curved concave wedge bar structure, DSM Screens are widely acclaimed for their efficiency and precision in various industrial applications ranging from wastewater treatment to mineral processing and beyond.

DSM Screens are meticulously crafted using high-quality stainless steel components to ensure durability and resistance to corrosion, making them suitable for demanding industrial environments. The key components include:

Wedge Wire Sieve Bend: The defining feature of DSM Screens is their curved concave wedge wire sieve bend design. This unique profile not only enhances structural integrity but also provides exceptional separation efficiency by facilitating precise cut points.

Support Structure: To maintain stability during operation, DSM Screens are reinforced with robust support rods and end bars. This structural framework ensures even distribution of material across the screen surface, optimizing separation efficiency and prolonging screen life.

Pneumatic Washing System: Many DSM Screens incorporate a pneumatically operated washing jet system. This feature enhances operational uptime by preventing material buildup and clogging on the screen surface, thereby extending maintenance intervals and maximizing productivity.

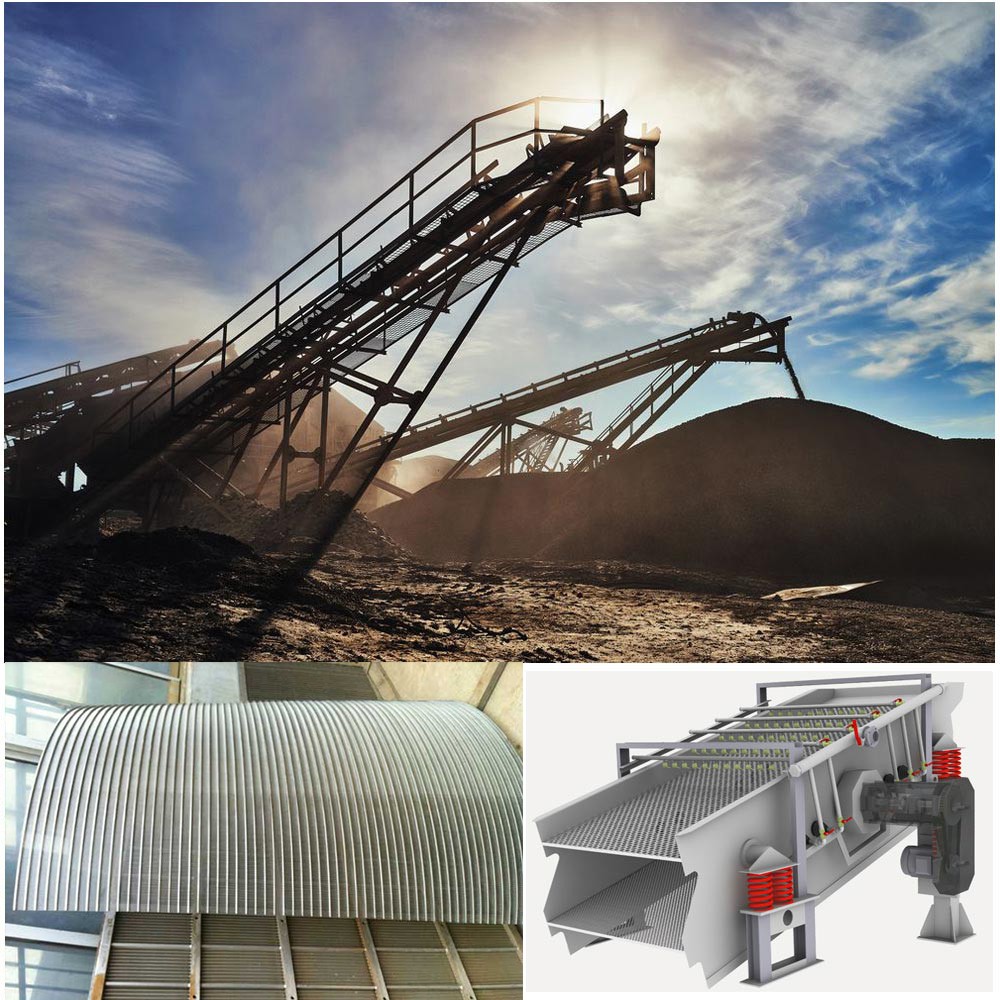

DSM Screens have a wide range of applications across diverse industries due to their versatility and effectiveness in solid-liquid separation processes:

Wastewater Treatment: In municipal wastewater treatment plants, industrial facilities, and agricultural operations, DSM Screens are pivotal in removing solids and impurities from wastewater streams. They play a critical role in meeting environmental regulations and producing clean water for reuse or discharge.

Mineral Processing: DSM Screens are indispensable in mineral processing operations for dewatering, classification, and sizing of mineral slurries. DSM Screens efficiently separates valuable minerals from gangue materials, contributing to improved resource recovery and downstream processing efficiency.

Sugar Refining: DSM Screens are used in sugar refineries to clarify and dewatering sugar juice. They effectively separate sugar crystals from the juice, ensuring the production of high-quality refined sugar with minimal impurities.

Paper Processing: DSM Screens play a crucial role in pulp screening and thickening applications within the paper industry. They help remove debris, fibers, and contaminants from pulp slurries, thereby enhancing paper product quality and production efficiency.

Food and Beverage Industry: DSM Screens are integral to various food and beverage processing applications, including fruit and vegetable processing, brewery operations, and dairy production. They aid in liquid separation and clarification, ensuring compliance with stringent food safety standards and maintaining product quality.

In chemical and pharmaceutical manufacturing, DSM Screens are employed for solid-liquid separation, product classification, and wastewater treatment. They contribute to maintaining product purity, consistency, and environmental sustainability by minimizing waste generation.

DSM Screens come in several configurations tailored to specific industrial needs:

Ideal for thickening and screening applications, this screen type is designed to handle dense slurries and achieve effective solid-liquid separation.

Used primarily for separating water suspensions, this screen type optimizes the separation of fine particles and liquids, making it suitable for a wide range of industrial processes.

Overall, DSM Screens stand as a versatile and reliable solution for numerous industrial applications, offering enhanced process efficiency, product quality, and environmental sustainability. Their innovative design and robust construction make them essential tools in modern industrial operations, making them suitable for various sectors.

QUICK CONTACT

YUBO is the Wedge wire DSM screen manufacturer in China, we can provide the custom filter solution service as your project requirements, please contact us if you have any questions.

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.